Multilayer heat-insulating and sound-insulating self-insulation hollow brick

A multi-layer heat insulation and self-preservation technology, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of large amount of mortar, increased difficulty in making blind hole bricks, and affecting the overall wall insulation and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

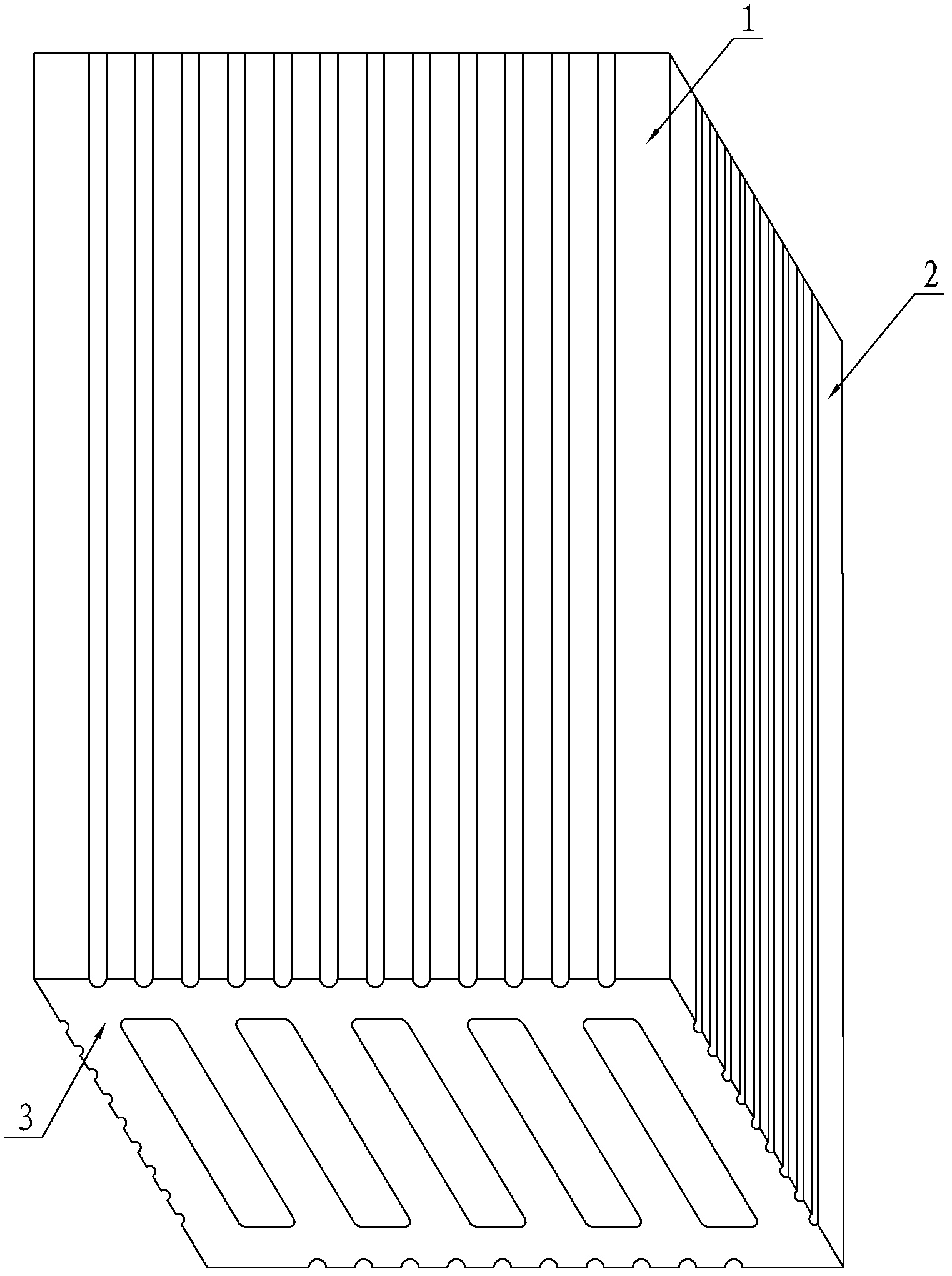

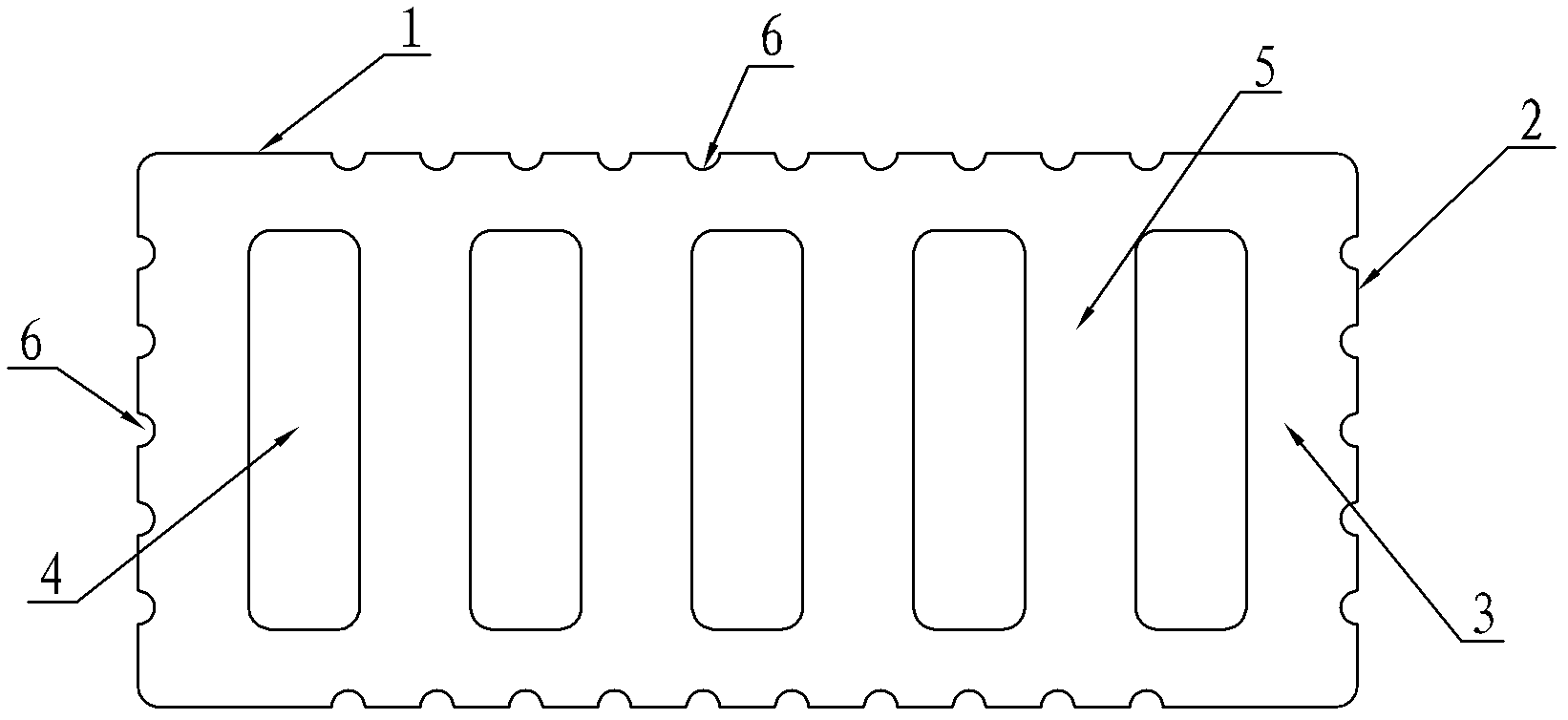

[0018] Embodiment 1: A kind of multi-layer heat insulation and sound insulation self-insulation hollow brick, such as Figure 1~3 As shown, it includes an upper and lower laminated surface 1, an exposed surface 2, and a butt joint surface 3. On the butt joint surface 3, five thermal insulation cavities 4 and four vertical pressure ribs 5 are arranged alternately. The thermal insulation cavities 4 are arranged along the The thickness direction of the brick body is vertically and equidistantly distributed, the wall thickness of the upper and lower laminated surface 1 is 8 mm, the thickness of the vertical pressure rib 5 is 8 mm, and the width of the thermal insulation cavity 4 is 8 mm. The exposed surface 2 is equipped with a slurry groove 6, and the depth of the slurry groove 6 is 1 millimeter, and the slurry groove 6 is parallel to the long side of the brick body.

Embodiment 2

[0019] Embodiment 2: Compared with Embodiment 1, the difference lies in the angle between the long side of the slurry tank 6 and the brick body. In this example, the angle between the slurry tank 6 and the long side of the brick body is 30° ~90°.

Embodiment 3

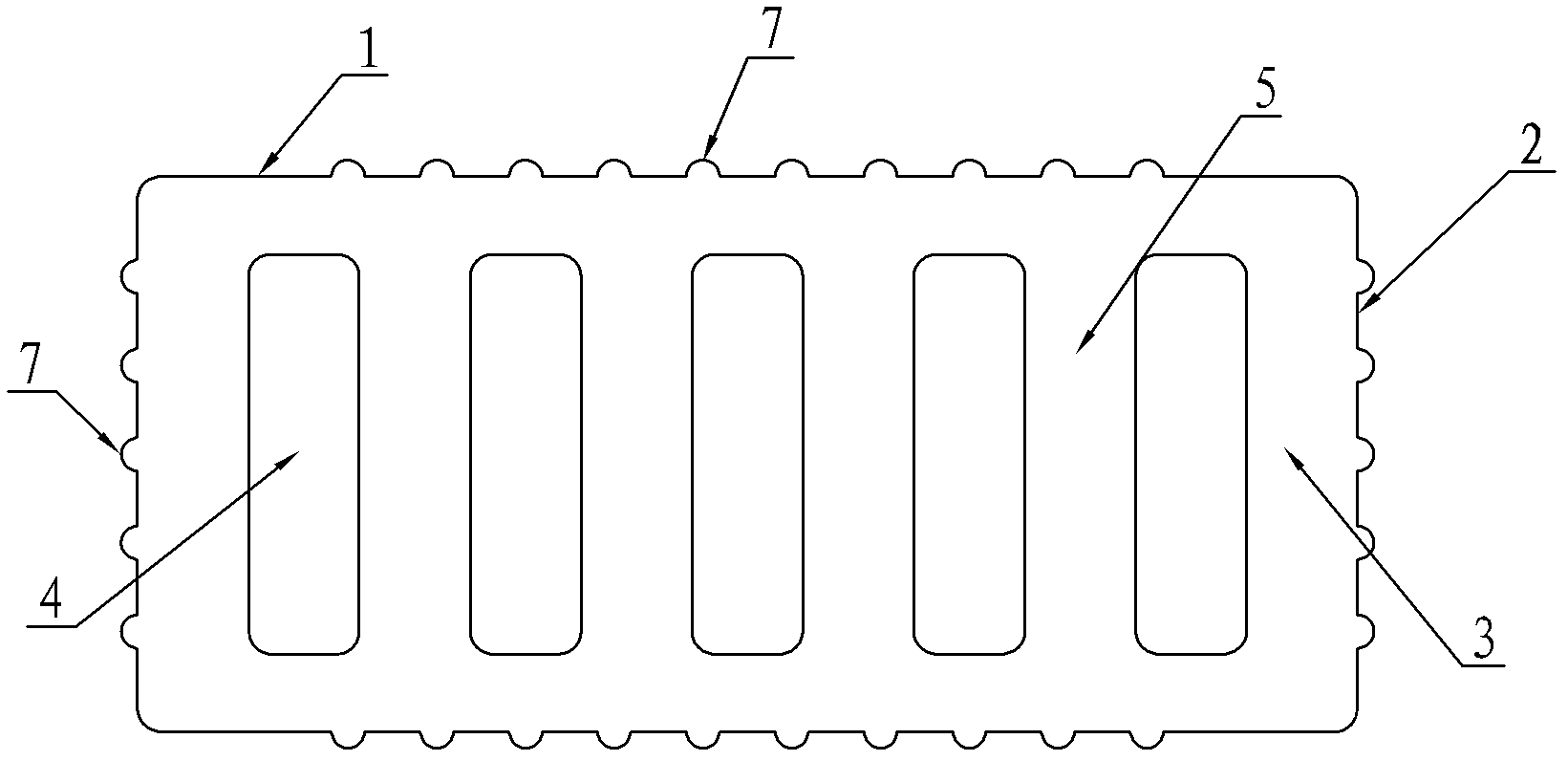

[0020] Embodiment 3: Compared with Embodiment 1, the difference is that the upper and lower laminated surfaces 1 and the exposed surface 2 are provided with convex body strips 7, and the height of the convex body strips 7 is 1 mm, and the convex body strips 7 and the brick body The angle between the long sides is 0°~90°.

[0021] There are many embodiments of the present invention, which cannot be exhausted. For example, the size of the heat insulation and sound insulation cavity 4 and the vertical pressure rib 5 can be designed according to people's requirements, as long as they have sufficient pressure bearing strength and heat insulation and sound insulation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com