Molding device and molding method for long spiral extruding rock-entering cast-in-place pile

A forming device and a long screw technology, applied in drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., can solve the problems of reducing pile end resistance, difficulty in ensuring pile body quality, and inability to effectively ensure grouting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

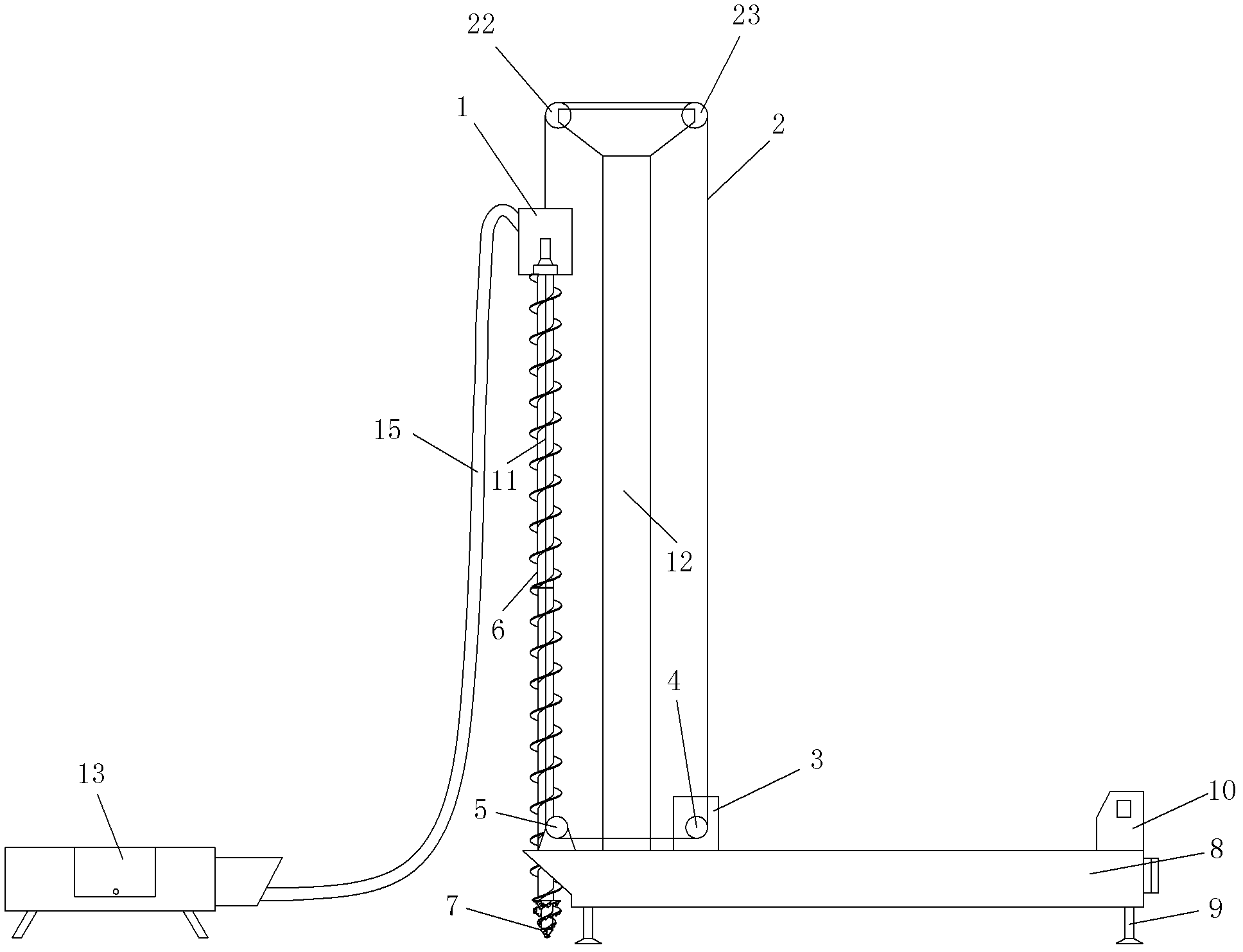

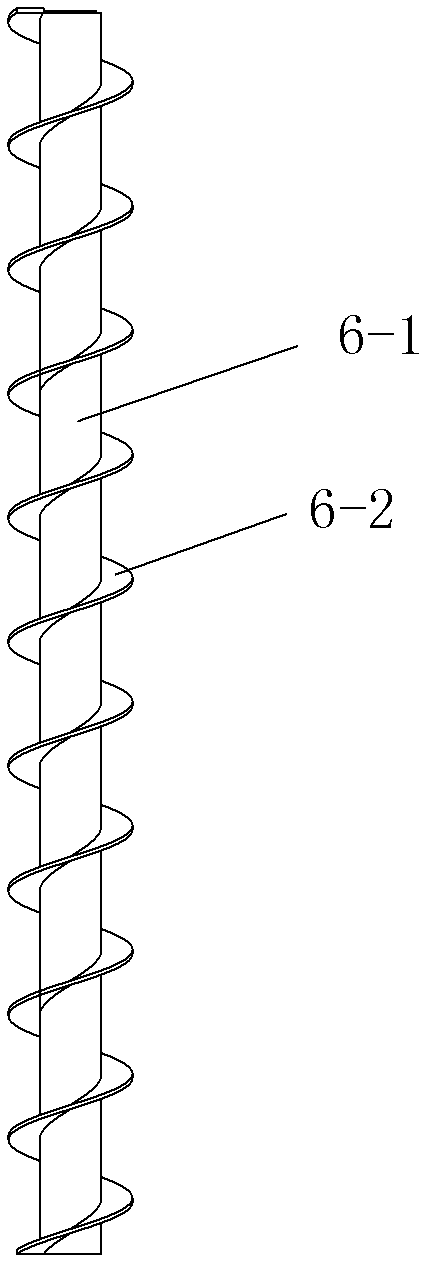

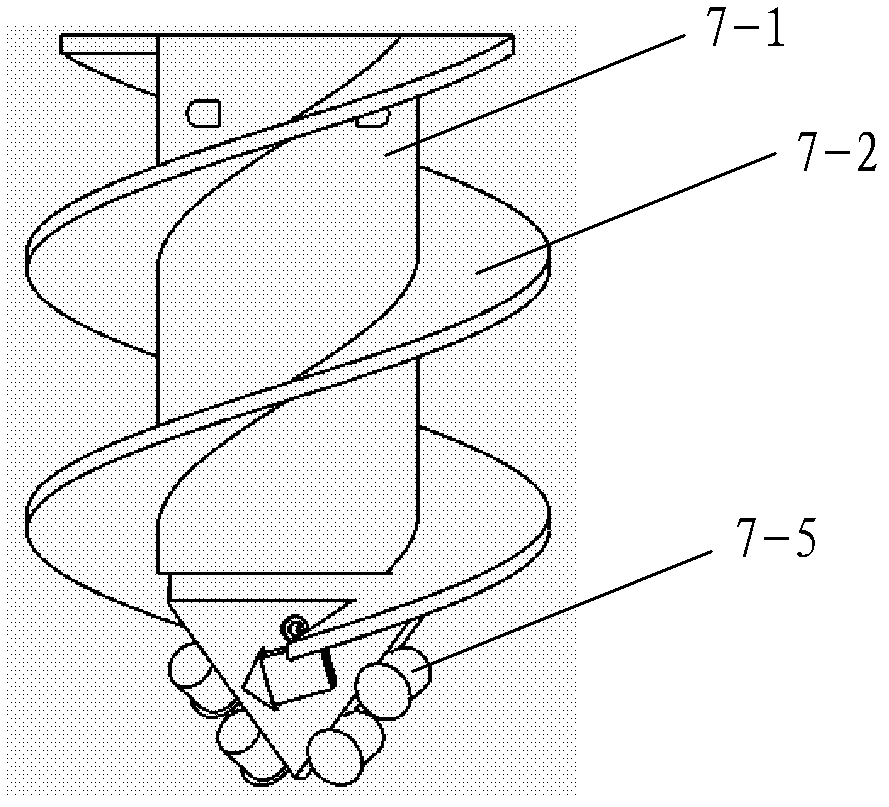

[0077] Such as figure 1 , Figure 9 A forming device for long spiral extruded cast-in-place piles shown includes drilling equipment formed by assembling a drill pipe 6 and a drill bit 7 coaxially installed at the bottom of the drill pipe 6. The lowering / lifting system for lifting the drilling equipment along the drilling direction after the drilling equipment is lowered and drilled in place, the electric rotary drive mechanism for driving the drilling equipment to rotate continuously, the lowering / lifting During the lifting process of the drill pipe 6, the system continuously injects grout into the formed borehole through the drill pipe 6 to form a grouting equipment for bored piles, and monitors the actual drilling depth of the drilling equipment in real time during the drilling process. The drilling depth / lifting height detection unit 4 that detects the actual lifting height of the drilling equipment in real time during the detection and lifting process, the drill rod torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com