Automatic cleaning device for garbage

A cleaning device and garbage technology, applied in the direction of road cleaning, cleaning methods, construction, etc., can solve the problems of inaccessible pedestrian streets and enterprise cleaning work, high production cost and use cost, large volume, etc., to achieve flexible contact or leave the ground, The effect of low production cost and use cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

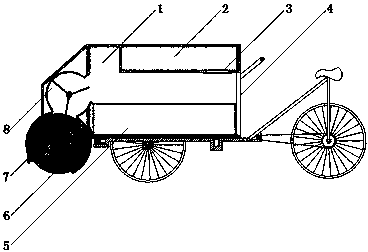

[0009] Such as figure 1 As shown, an automatic garbage cleaning device of the present invention includes a cleaning device, a vacuum cleaner 8 and a dustbin 1 . The cleaning device includes a dust suction chamber, a cleaning cylinder 6 and a power unit. There is an opening at the bottom of the dust suction chamber, and the outer wall of the dust suction chamber is welded together with the dustbin. Of course, common methods such as threaded fasteners can also be used for fixed connection. The cleaning cylinder 6 includes a transmission shaft and a brush cylinder fixed on the transmission shaft. The cleaning cylinder 6 is placed in the dust suction chamber, and the transmission shaft is connected with the side wall of the dust suction chamber through a bearing. The brush cylinder is fixedly connected to the transmission shaft of the cleaning cylinder th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com