Hanging side formwork of cradle

A side formwork and suspension technology, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of heavy weight of hanging basket side formwork, difficult deformation control, and high construction cost, so as to reduce equipment investment costs and solve instability , to overcome the effect of horizontal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

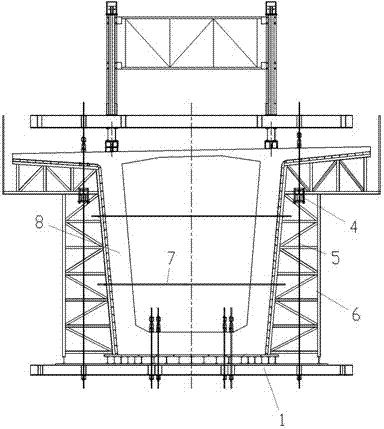

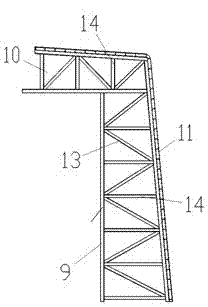

[0017] like figure 1 As shown, the suspension side formwork of the hanging basket of the present invention includes a side formwork 6, a finish-rolled rebar 7, and a suspension device 5.

[0018] 1) The side formwork 6 retains the necessary ground support steel, and the flange formwork is mainly a cantilever structure to minimize the amount of materials used.

[0019] 2) The side template 6 rests on the track beam 4, and is suspended on the poured beam section 8 and the front beam of the hanging basket through the track beam 4. The suspension device 5 is Φ36 fine-rolled rebar and matching nut backing plate. The finish-rolled rebar is stretched and pre-tightened to adjust the elevation of the side formwork, and make the side formwork 6 close to the poured beam section 8 .

[0020] 3) The two left and right side formworks 6 are pulled against each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com