Atmosphere isolation device between vacuum chambers

A technology of isolation device and vacuum chamber, which is applied in vacuum evaporation plating, electrical components, ion implantation plating, etc., can solve the problems of uneven film layer, impact, increase equipment complexity and cost, etc., and achieve good isolation effect, The effect of reducing equipment cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The feature of the present invention is that it combines the gas sealing technology and the differential technology while avoiding the design of the isolation chamber. The present invention will be described in further detail below in conjunction with the accompanying drawings.

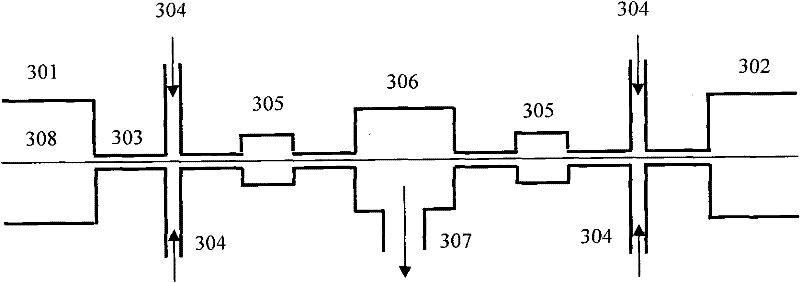

[0024] Such as image 3 As shown, the vacuum chamber atmosphere isolation device provided by the preferred embodiment of the present invention includes adjacent reaction chambers 301 and 302 , an air inlet 304 is provided on the slit 303 , gas mixing chambers 305 , 306 and an air extraction port 307 . The flexible substrate 308 is coated in different reaction chambers. The air inlet is filled with inert gas or gas shared by adjacent reaction chambers, such as H2 or N2, through the control of the mass flow meter. The pumping system of the pumping port 307 adopts a separate mechanical pump or a pumping system composed of a molecular pump and a mechanical pump. The gas flow rate of the gas inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com