Method of preparing biomass charcoal with biomass material and carbonization furnace

A technology of biomass materials and biochar, applied in the direction of biofuels, fixed carbonization furnaces, coke ovens, etc., can solve the problems of uncontrollable pyrolysis temperature, etc., and achieve the effects of compact structure, reduced pollution, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

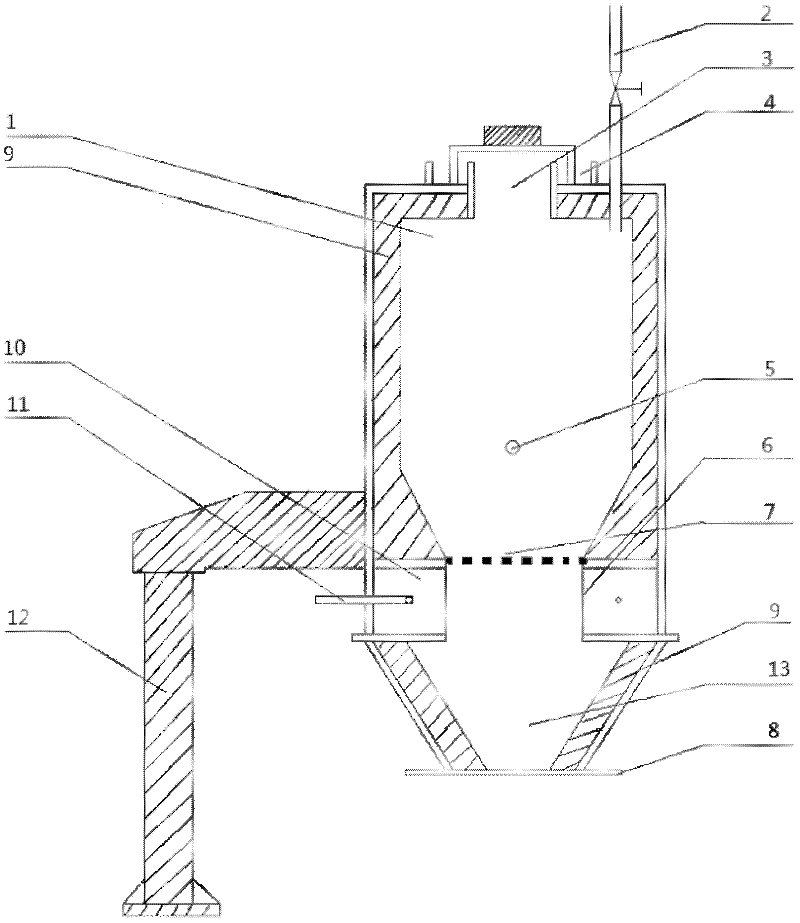

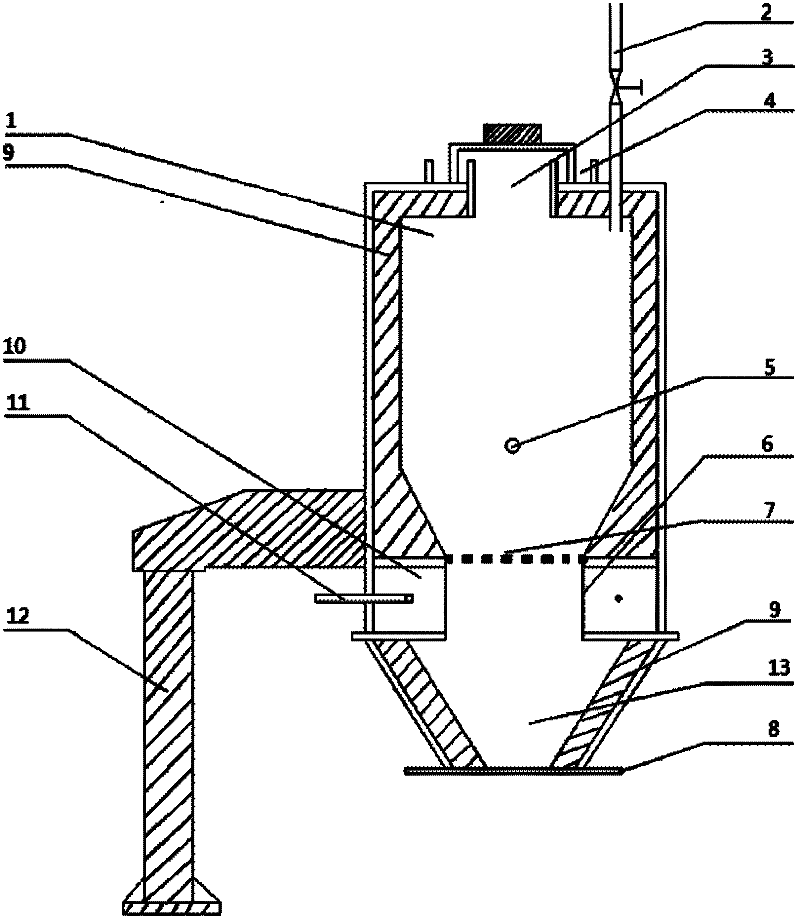

[0026] The carbonization furnace involved in the present invention includes a furnace body. The inner wall of the furnace body is covered with a high temperature resistant heat insulating material. Zone 6 and bucket-shaped unloading zone 13, wherein, the lower part of the carbonization chamber 1 is a bucket-shaped structure, and the center of the electric heating zone 6 is a straight-through channel for discharging, the lower edge of the bucket-shaped structure is connected with the upper edge of the straight-through channel for discharging, and the electric heating zone and The intersection of the carbonization chamber is provided with a mesh-shaped movable fire grate 7, the movable fire grate 7 can be switched on and off through the connecting rod, and the annular electric heating tube 11 is coiled around the discharge channel; the feeding port 3 is equipped with a sealing cover 4. The sealing cover is sealed with water, and the outlet of the bucket-shaped discharge area 13 i...

Embodiment 2

[0030] Corn stalks are used as the main raw material, and after being dried in the sun to remove residual soil impurities, they are chopped into pieces with a length of about 10cm. Fill the above-mentioned crushed corn stalks into the carbonization chamber 1 through the feed port of the carbonization furnace described in Example 1 (the same below), and compact them in layers until the entire carbonization chamber is filled (10 kg of corn stalks) , cover the sealing cover 4, the sealing baffle plate 8 of the outlet of the bucket-shaped discharge area 13, open the airflow adjustment device 2 at the top of the carbonization chamber 1, turn on the power controller, and adjust the temperature of the carbonization chamber 1 through the annular electric heating tube 11 After the temperature of the carbonization chamber reaches 90°C and keeps for 6 hours, adjust the carbonization chamber to 200°C and keep it warm for 2 hours for pre-carbonization. After the pre-carbonization is comple...

Embodiment 3

[0033] Rice straw is used as the main raw material, after being dried in the sun to remove residual soil impurities, it is chopped into fragments with a length of about 10cm. Fill the processed rice straw fragments into the carbonization chamber 1 from the carbonization furnace feed port, tamp them in layers, cover the sealing cover 4 until the entire carbonization chamber is filled (the rice straw fragments are 8 kg), and then cover the sealing cover 4. Close the sealing baffle 8 of the outlet of the bucket-shaped discharge area 13, open the airflow adjustment device 2 at the top of the carbonization chamber 1, turn on the power controller, and adjust the temperature in the carbonization chamber 1 to 90 through the annular electric heating tube 11. ℃, keep it for 6h, then adjust the carbonization chamber to 200℃, keep it warm for 2h for pre-carbonization. After the pre-carbonization is completed, the airflow regulating device 2 is closed, the carbonization temperature in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com