Acrylate adhesive for spot welding process

An acrylate and adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of troublesome spot welding process, easy to catch fire, etc. Effect

Active Publication Date: 2012-07-04

HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Generally speaking, acrylic adhesives are flammable, especially when spot welding is easy to catch fire and burn, which brings great trouble to the spot welding process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

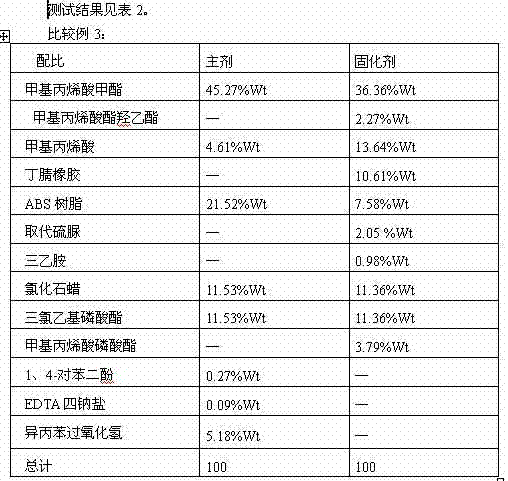

[0023] The following Examples and Comparative Examples will illustrate the present invention in more detail, but the present invention is not limited thereto.

[0024]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

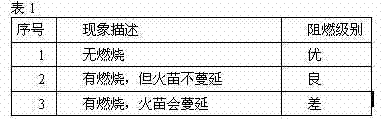

The invention relates to an acrylate adhesive for a spot welding process and belongs to the technical field of a double-component acrylate structural adhesive, and is mainly used for solving the problems that the existing acrylate adhesive is extremely easy to ignite and burn when in spot welding. The acrylate adhesive is characterized by mainly comprising a main agent component and a solidifyingagent component, wherein (1) the main agent component comprises the following raw materials by weight percent: 42%-85% of acrylate monomer containing at least one vinyl group, 0%-12% of methacrylic acid, 0%-30% of elastomer, 0.01%-1% of stabilizing agent, 0%-30% of toughening resin, 0%-20% of fire retardant and 0.5%-8% of peroxide; (2) the solidifying agent component comprises the following raw materials by weight percent: 40%-90% of acrylate monomer containing at least one vinyl group, 0%-23% of elastomer, 0%-20% of methacrylic acid, 1%-10% of accelerating agent, 0%-30% of toughening resin and 0%-20% of fire retardant; and (3) at least one component in the main agent and the solidifying agent contains 10%-30% of elastomer. The acrylate adhesive disclosed by the invention has the characteristic that the adhesive can be used for the spot welding process and can be widely applied to the fields of machinery manufacturing and maintenance.

Description

technical field [0001] The invention belongs to the technical field of two-component acrylate structural adhesives. In particular, it relates to an acrylic adhesive for spot welding process. Background technique [0002] Because the fast-curing acrylate structural adhesive has the remarkable characteristics of rapid curing at room temperature, high strength, good toughness, oily surface bonding, strong adaptability, and simple process, it is widely used in aerospace, aviation, automobiles, machinery, ships, Structural bonding, small-piece assembly, large-piece assembly, emergency repair, anti-seepage plugging, nameplate pasting, etc. It has also been well applied in cutting-edge technology and high technology. [0003] Generally speaking, acrylate adhesives are flammable, especially during spot welding, they are very easy to catch fire and burn, which brings great trouble to the spot welding process. In order to adapt to the spot welding process, it is necessary to develo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J4/02C09J4/06

Inventor 桂武标韩胜利马燕

Owner HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com