Hierarchical zeolite, preparation and application thereof

A channel and zeolite technology, applied in the field of catalyst preparation and application, can solve problems such as poor crystallization, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

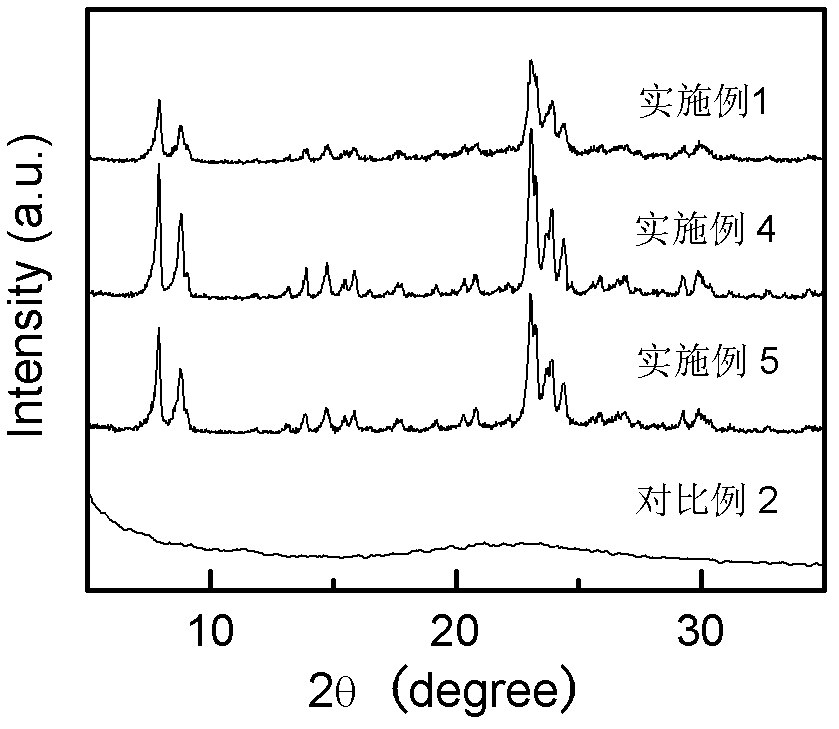

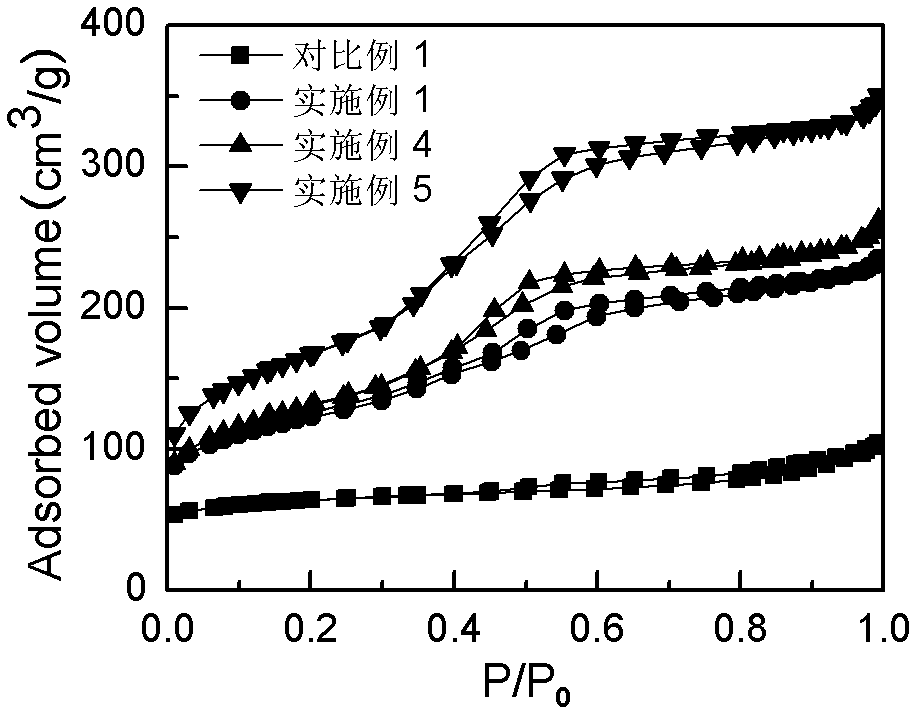

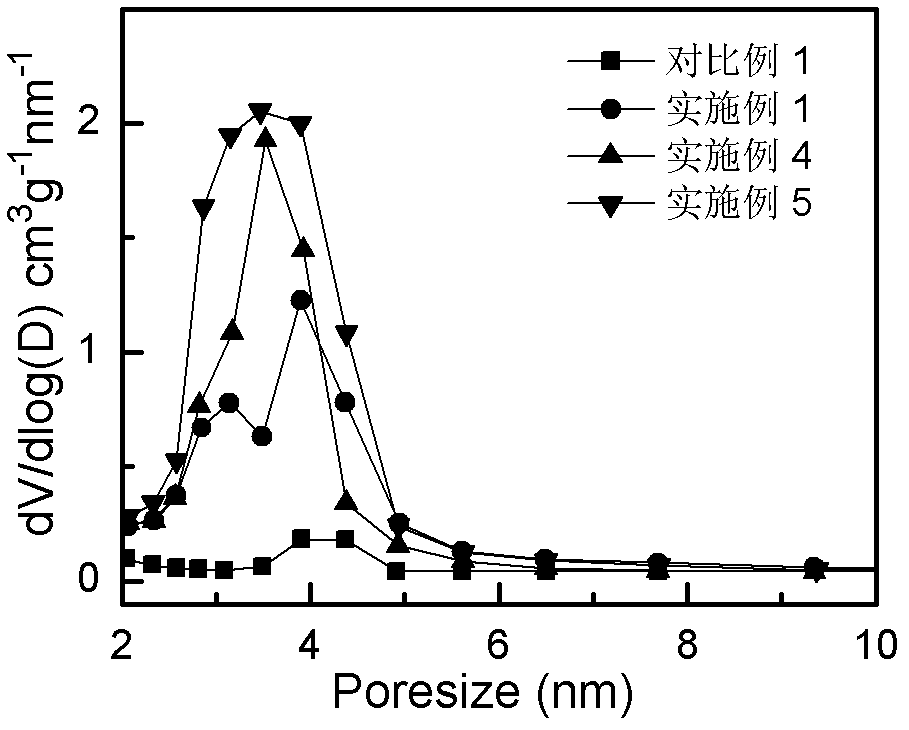

[0033] According to the ratio of SiO 2 :TPOAC:TPAOH:Na 2 O:Al 2 o 3 :H 2 O=1:0.03:0.3:0.06:0.02:80 to configure the solution, the specific steps are as follows: TPAOH, H 2 O, NaOH, NaAlO 2 Prepare a solution with TPOAC (trimethoxysilylpropyldimethyloctadecylammonium chloride), stir evenly, then add TEOS dropwise, stir for 18 hours, heat with microwave power of 800W, and crystallize at 80°C for 0.5 h, and then crystallized at 165°C for 3h, the obtained product was filtered, washed with deionized water until neutral, dried at 110°C for 12h, and then calcined at 550°C for 6h to remove the template to prepare the multi-level channel ZSM-5. The XRD spectrum can be seen as MFI structure, and the SEM and TEM photos can be seen that the synthesized zeolite is about 2 μm in size and has a mesoporous structure. The nitrogen adsorption results show that it is a type IV isotherm, indicating that it has a mesoporous structure and a pore size of 4 nm. left and right, such as Figure ...

Embodiment 2

[0035] According to the ratio of SiO 2 :TPOAC:TPAOH:Na 2 O:Al 2 o 3 :H 2 O=1 : 0.01 : 0.3 : 0.06 : 0.02 : 80 to prepare the solution, and the other process steps and process conditions are the same as in Example 1, and the multi-level channel ZSM-5 can be prepared.

Embodiment 3

[0037] According to the ratio of SiO 2 :TPOAC:TPAOH:Na 2 O:Al 2 o 3 :H 2 O=1 : 0.05 : 0.3 : 0.06 : 0.02 : 80 to prepare the solution, and the other process steps and process conditions are the same as in Example 1, and the multi-level channel ZSM-5 can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com