Stepping type pipeline arranging device

A step-by-step, pipeline technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of pipeline interruption, increase, and inability to ensure the continuity of pipeline delivery, so as to ensure the continuity of pipeline delivery and improve the efficiency of pipeline delivery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

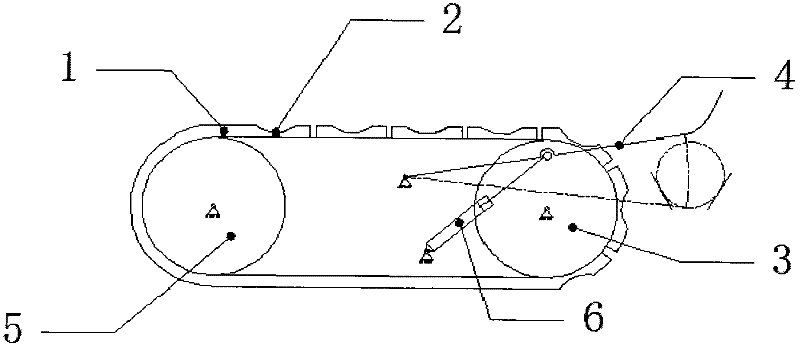

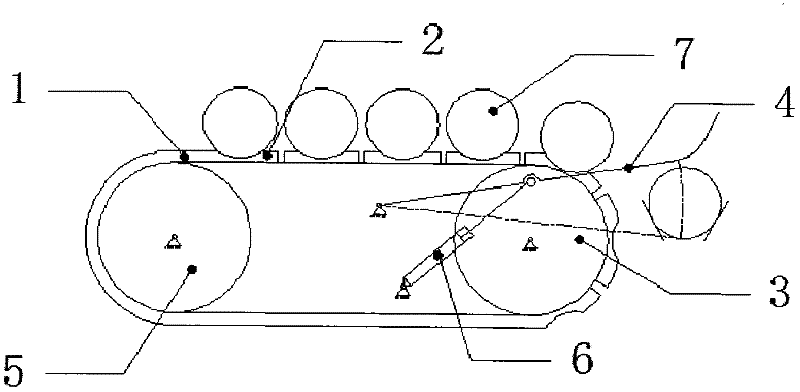

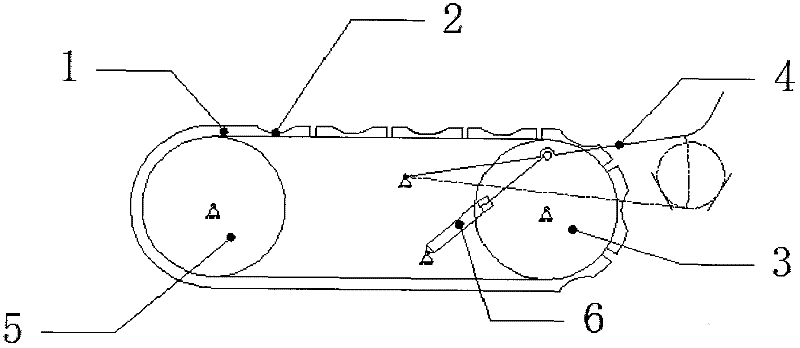

[0015] Such as figure 1 As shown, the present invention comprises: crawler conveyor belt 1, the swing arm 4 of end arc and the hydraulic cylinder 6 of control swing angle, and crawler conveyor belt 1 is provided with the driving wheel 3 that can rotate bidirectionally, and crawler conveyor belt Each crawler plate of 1 is provided with arc-shaped buffer isolation groove 2, in order to place pipeline 7. A swing arm 4 with an arc-shaped end is installed on one side of the frame of the crawler conveyor belt 1, and the hydraulic cylinder 6 is hingedly installed on the frame at the lower side of the swing arm 4, and the piston rod of the hydraulic cylinder 6 is hinged on the swing arm 4 , to control the swing angle of the swing arm 4 through the expansion and contraction of the piston rod. The initial angle of the swing arm 4 is: make its arc slightly lower than the horizontal plane of the crawler conveyor belt 1 . The two queuing machines are arranged at about 1 / 3 and 2 / 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com