Stone board unloader

A kind of unloading machine, stone technology, applied in conveyors, loading/unloading, mechanical conveyors and other directions, can solve the problems of harsh working environment, prone to accidents, joint injuries and cracks, etc., to improve the working environment, avoid Work-related accidents, the effect of work comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

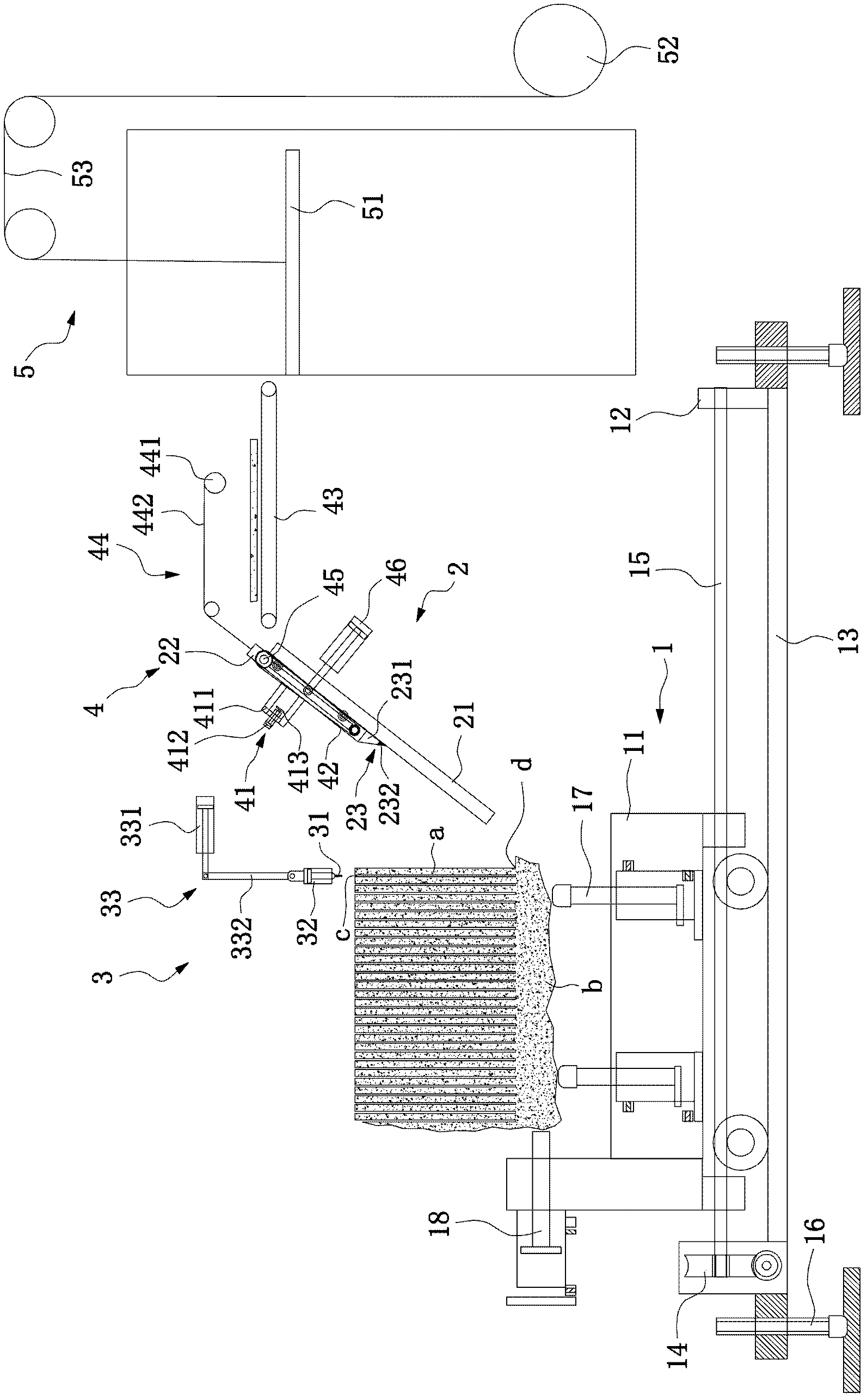

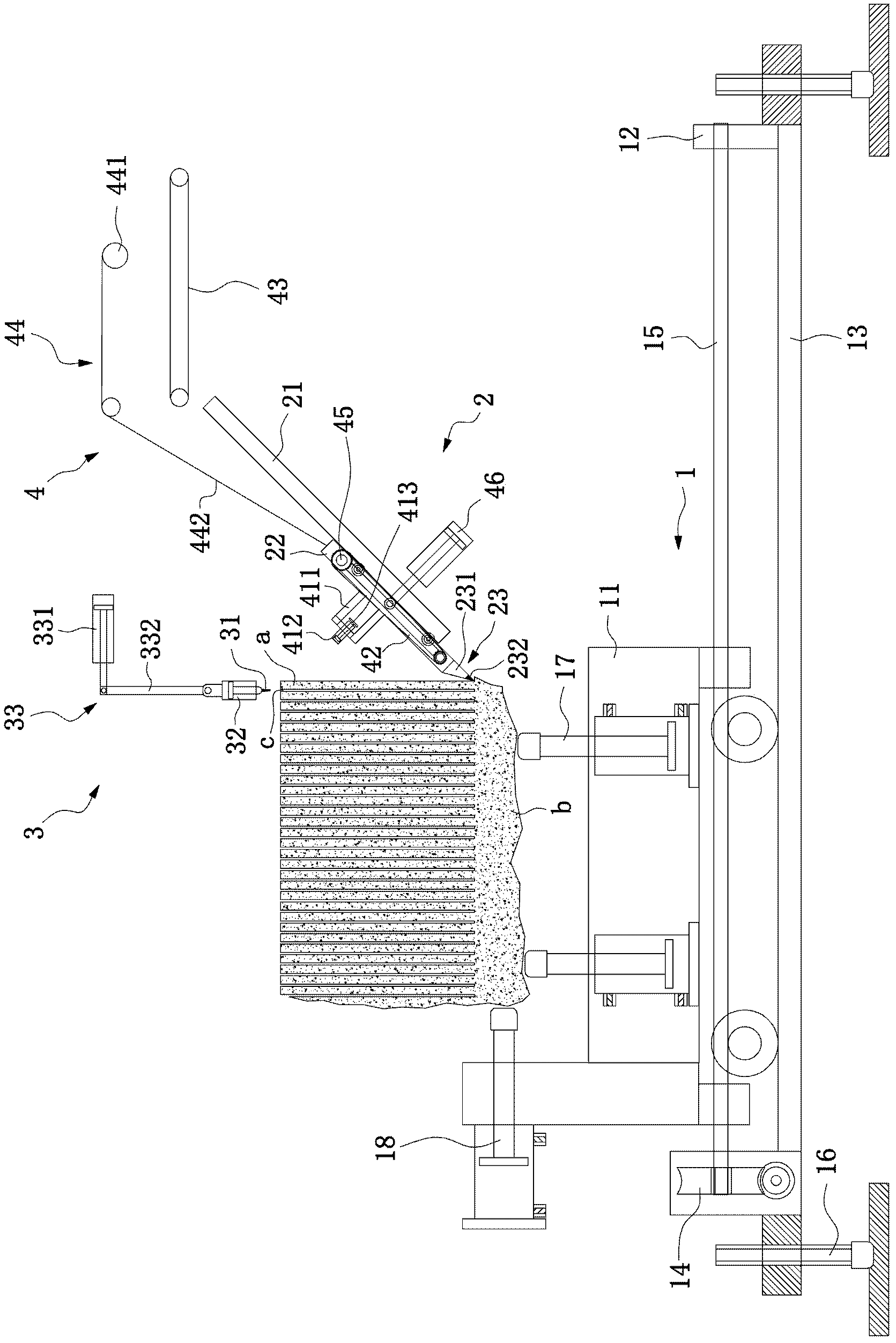

[0034] The technical solution will be further described below in conjunction with the accompanying drawings.

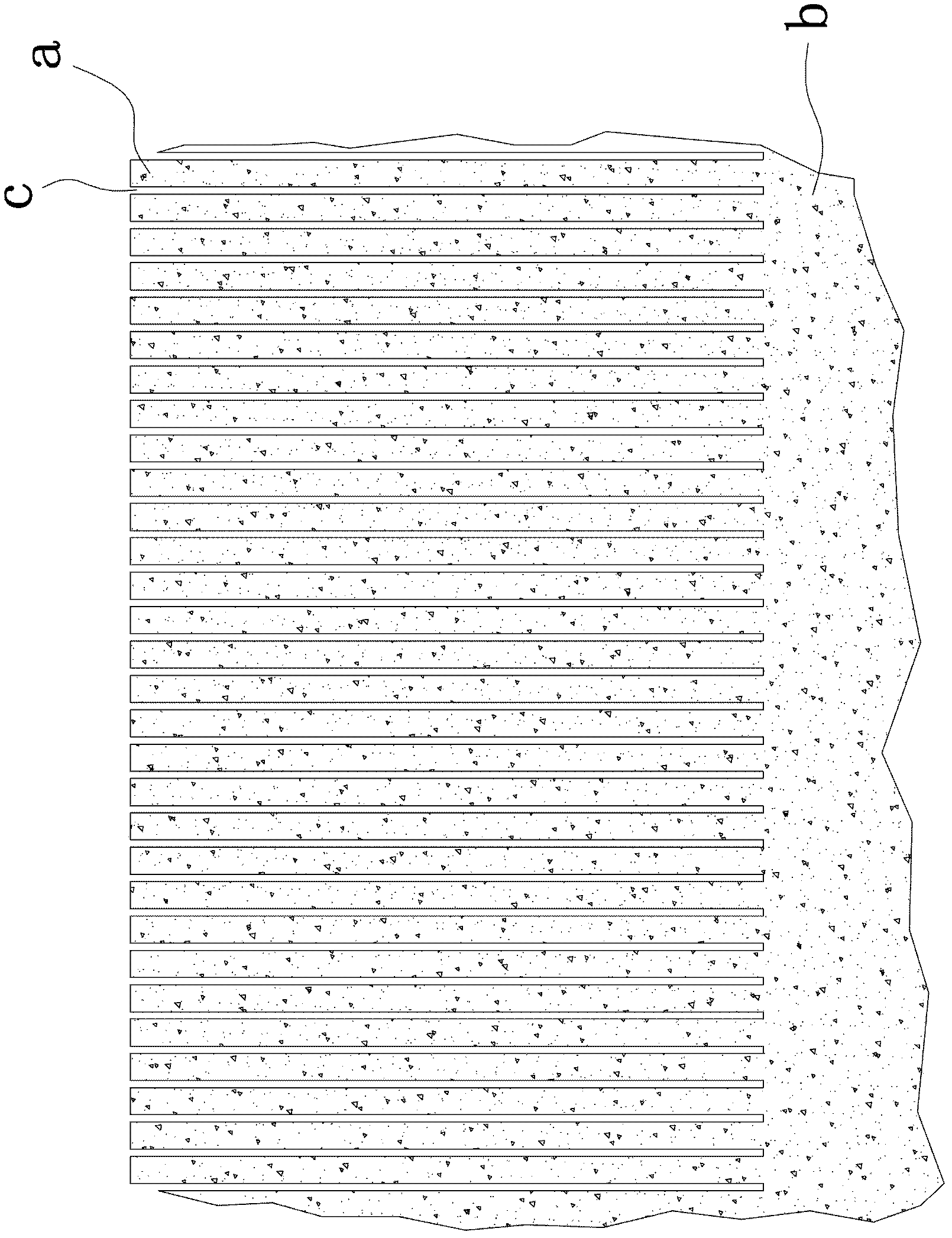

[0035] The stone unloading machine of this embodiment includes a stone transporting device 1 capable of stepping movement, an impact device 2 that hits the joint between the stone slab a and the stone main body b, and a stone slab that separates the stone slab a after the joint is injured from the stone main body b Device 3, the stone slab conveying device 4 for transporting the stone slab a and the stacking device 5 for stacking the stone slabs a, the conveying device 4 is located on the trajectory where the stone slab is detached from the stone body b and turned over after being pried by the detachment device 3, and the stacking device 5 is located at the conveying device 4 behind.

[0036] Below we describe the above devices in detail one by one:

[0037] Stone transportation device: The stone transportation device 1 is composed of a stone transportation vehicle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com