Method for manufacturing individually assembled printed products

A kind of printed matter, special technology, applied in printing, printing machine, rotary printing machine, etc., can solve the problem of high cost and achieve the effect of reliable distinction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

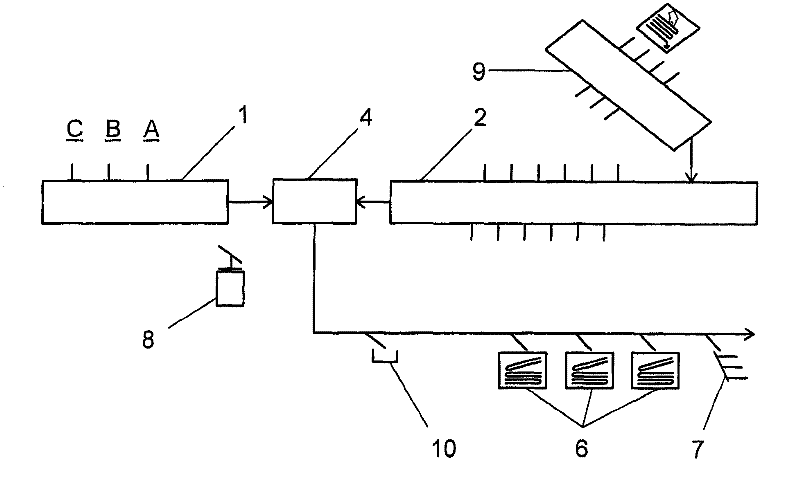

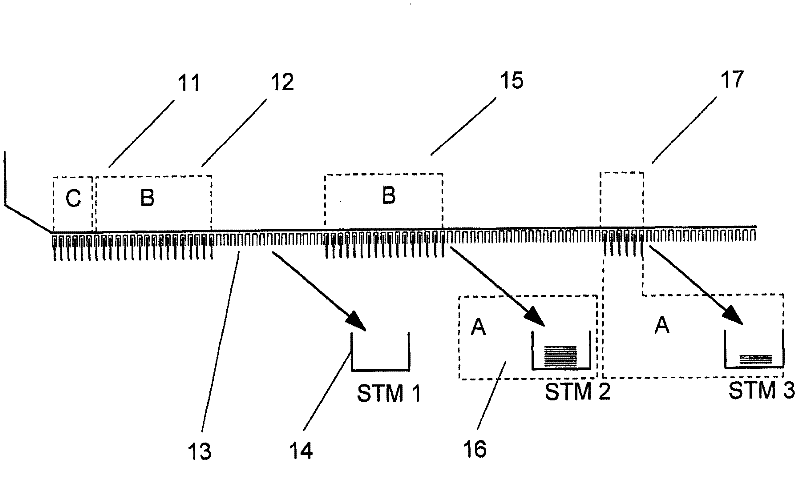

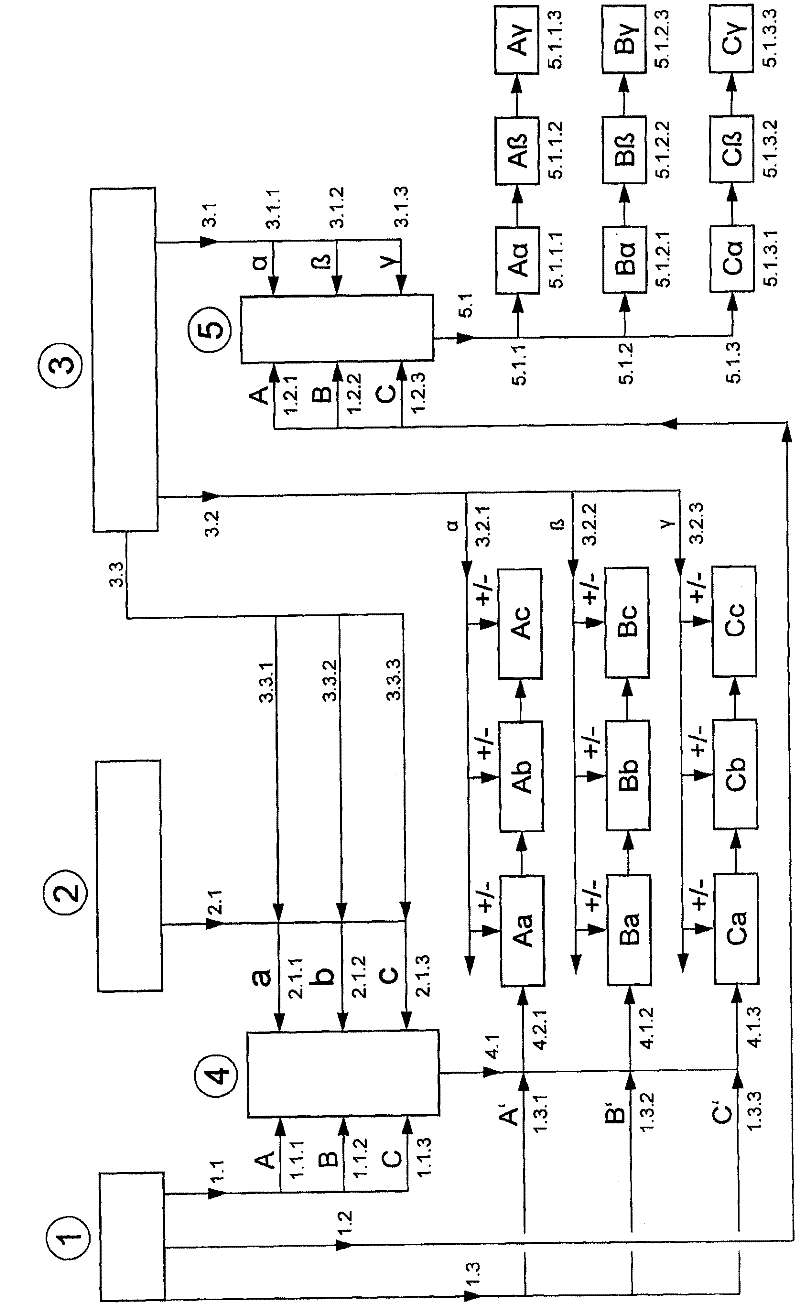

[0055] figure 1 The working principle of a device consisting of different elements in operative connection with each other is shown. The first mechanical device 1 fulfills the task of removing the different jacket articles A, B, C in such a way that there is no gap between the two jacket articles. The mechanical device 1 constitutes one of the branches of the plant. The other branch of the device is formed by a second mechanism 2 , which undertakes the task of ensuring the transport and provision of any accessory composition. The two branches formed by the first and second devices 1 , 2 converge into a splicing device 4 , in which the integration of a specific cover article with a specific accessory composition takes place. Furthermore, the device is widened by a further mechanism 9 for modularly widening the insertion possibilities. As a result, the space conditions within such a device can be used optimally. In this case, a combination of two gathering elements results w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com