Silicone rubber composite rubber tube lined with polytetrafluoroethylene and manufacturing method thereof

A technology of polytetrafluoroethylene and composite rubber hose, which is applied in the direction of rubber layered products, laminated, layered products, etc., and can solve the problem of large thickness of polytetrafluoroethylene lined pipe, poor oil resistance, poor solvent resistance, and low sealing performance And other problems, to achieve the effect of improving the scope of use, low equipment cost, and perfect sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

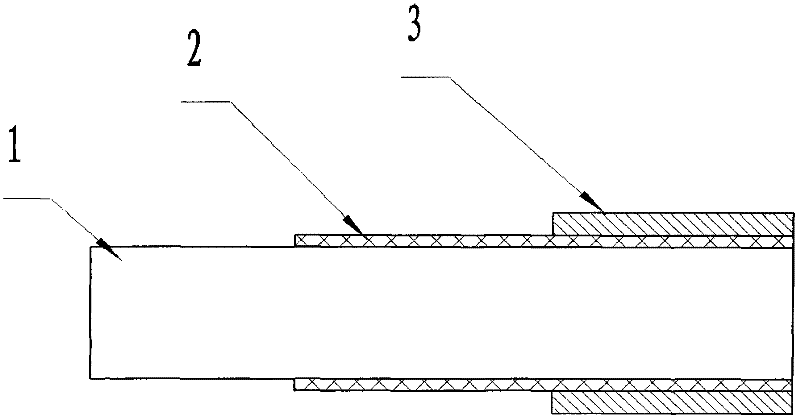

[0020] Attached below Figure 1-2 The silicone rubber composite hose of the present invention and its manufacturing process will be described in detail.

[0021] A manufacturing process of a silicone rubber composite hose with polytetrafluoroethylene as an inner liner, comprising the following steps: performing plasma treatment on a polytetrafluoroethylene film strip 2; winding the polytetrafluoroethylene film strip 2 after plasma treatment on the On the mold core 1 of the required size, different layers can be wound according to needs; the glass tape 3 is wound on the outer layer of the polytetrafluoroethylene film tape 2, and then heated and shaped. After the shaping is completed, the glass tape 3 is removed to form a polytetrafluoroethylene inner layer. For the liner 4, evenly coat the surface of the tetrafluoroethylene liner 4 with sodium-naphthalene-tetrahydrofuran solution or directly immerse in the sodium-naphthalene-tetrahydrofuran solution; use alcohol and water to cl...

Embodiment 2

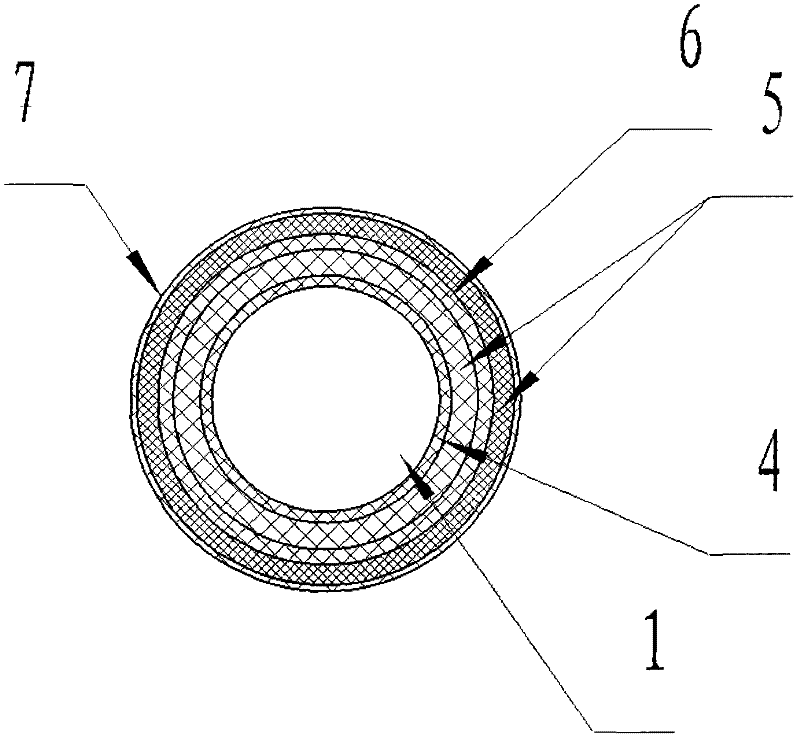

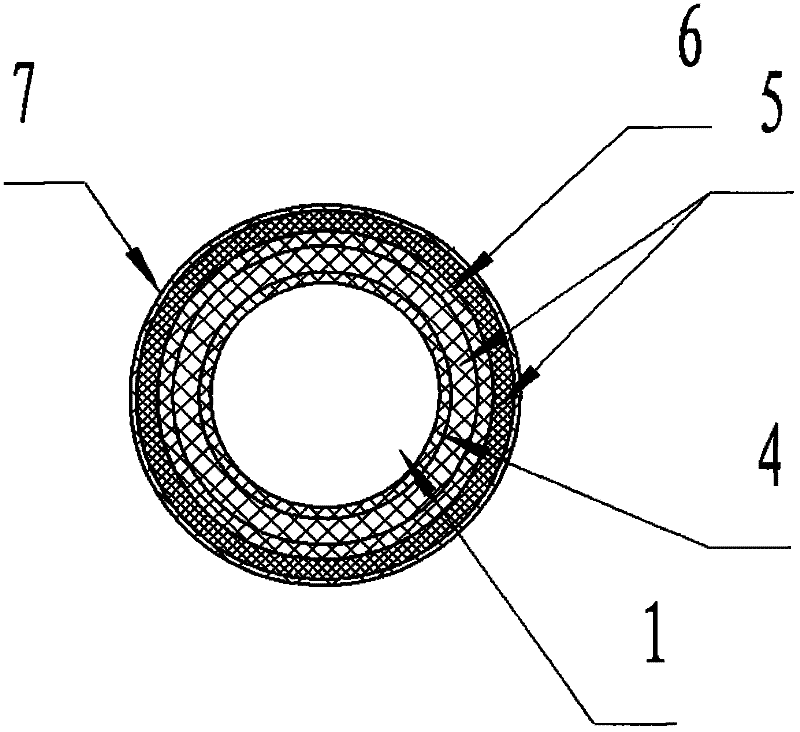

[0031] see figure 2 , a silicone rubber composite hose comprises from the inside to the outside in sequence: a polytetrafluoroethylene liner 4; a first silicone rubber layer 5; a reinforcing layer 6; and a second silicone rubber layer 5. Preferably, the reinforcing layer 6 may preferably include polyester fiber cloth, glass cloth, or carbon fiber cloth.

[0032] Preferably, the silicone rubber composite hose can be manufactured through the following manufacturing process. Specifically, 1 firstly, place the polytetrafluoroethylene film strip 2 in the plasma chamber, under the pressure of 100pa, the oxygen flow of 10L / min and the power of 350W, do plasma bombardment treatment for 3min; 2 place the polytetrafluoroethylene film after plasma treatment Belt 2 is wound on the mold core 1 of the required size, and different layers can be wound according to needs; after 3 is wound, a layer of glass tape 3 is wound on the outer layer of PTFE film tape 2, and then it can be heated in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com