steel bar bending machine

A hoop bending machine and steel bar technology, applied in the field of steel bar hoop bending machines, can solve the problems of high manufacturing precision, complicated equipment, labor intensity of time-consuming and laborious workers, etc., and achieve the effect of improving work efficiency, good dimensional consistency, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

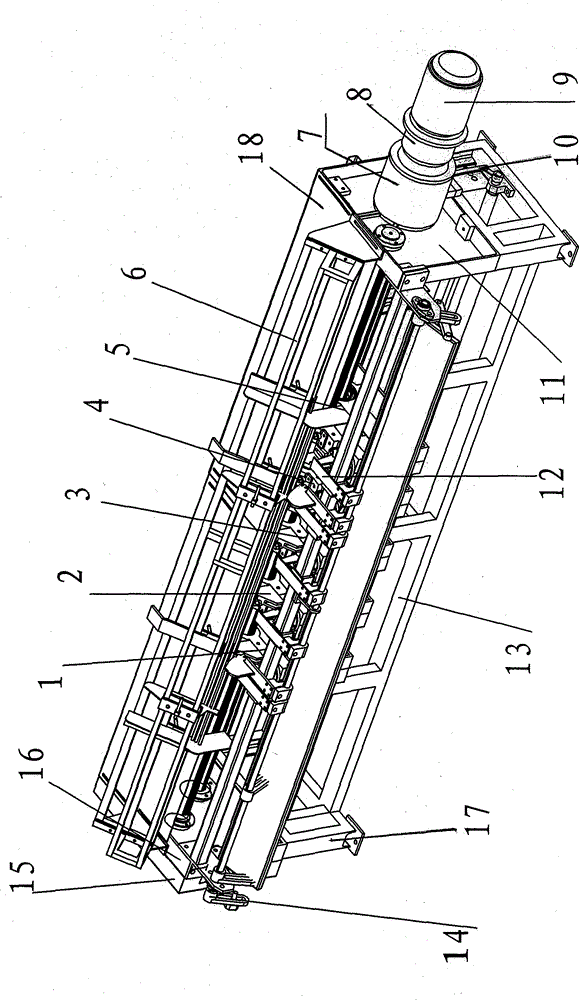

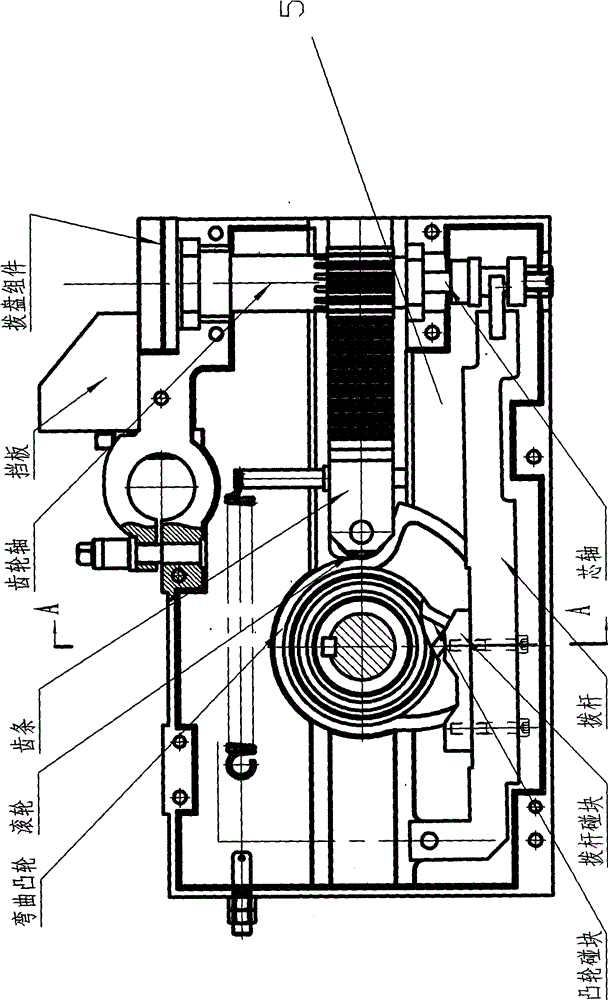

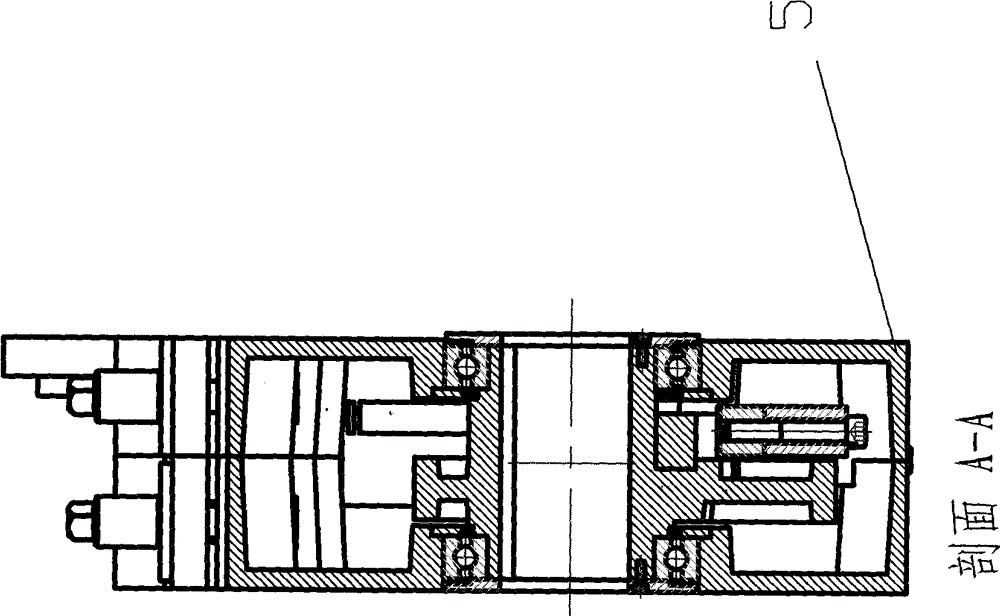

[0019] A steel hoop bending machine according to the present invention comprises: a left chassis, a middle chassis 3, a right chassis, a discharge rack assembly 6, a clutch box 7, a reducer 8, a motor 9, a pedal clutch assembly 10, and a right end plate 11 , binder plate 12, front beam assembly 13, cam swing rod assembly 14, protective cover 15, left end plate 16, frame 17, upper cover plate 18, bending cam 19, roller 20, rack 21, rack return spring 22 , Hollow gear shaft 23, mandrel 24, dial assembly 25, cam bumper 26, lever bumper 27, lever 28, dial slot 29, damping pad 30, adjustment nut 31, adjustment screw 32, adjustment rod 33. Flat pin 34, rotating arm 35, dial 36, and baffle 37, characterized in that: the left and right parts of the frame 17 are combined and assembled, the top has an upper cover 18, and both ends are equipped with a left end plate 16 and a righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com