Safe self-destroying syringe

A self-destructing syringe technology, applied in the field of medical devices, can solve the problems of affecting tightness, no adjustment space, high injection cost, etc., and achieve the effect of preventing abnormal displacement, avoiding repeated use, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

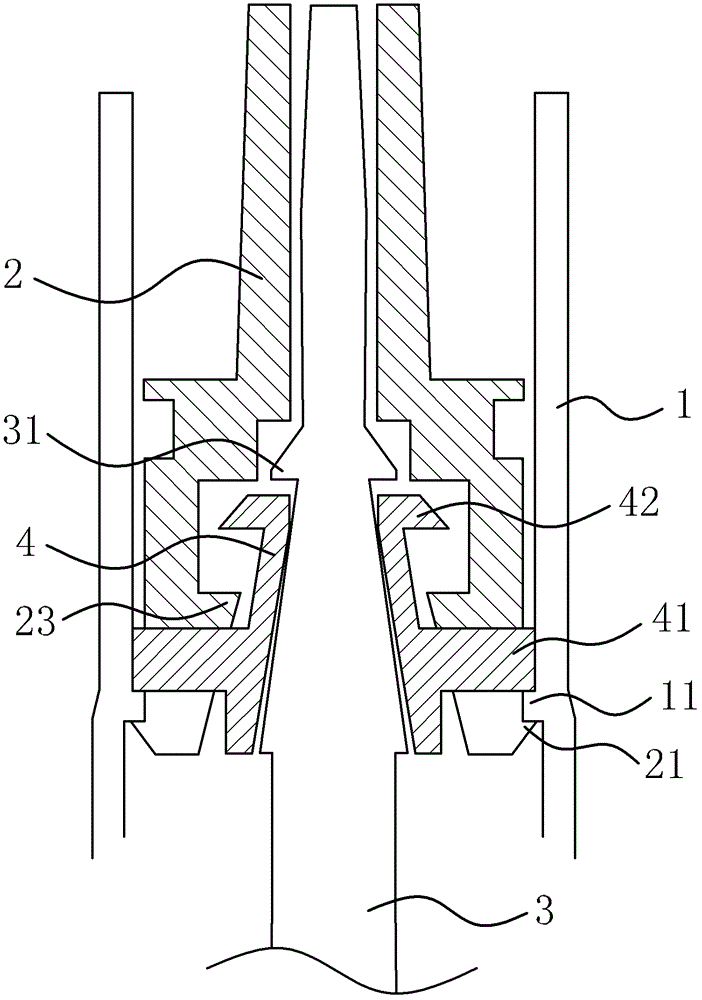

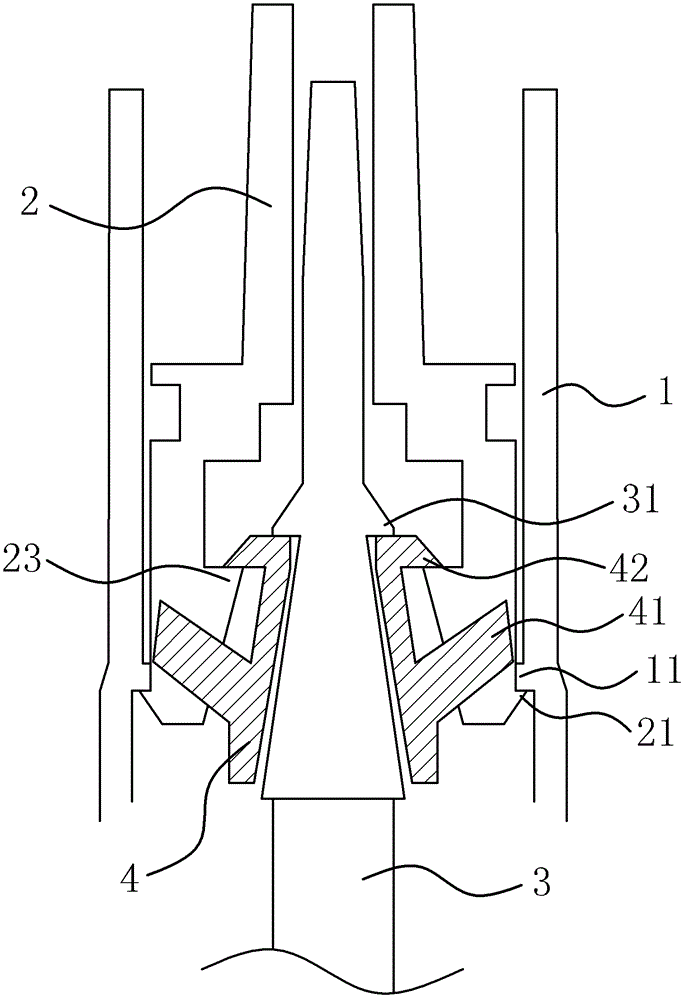

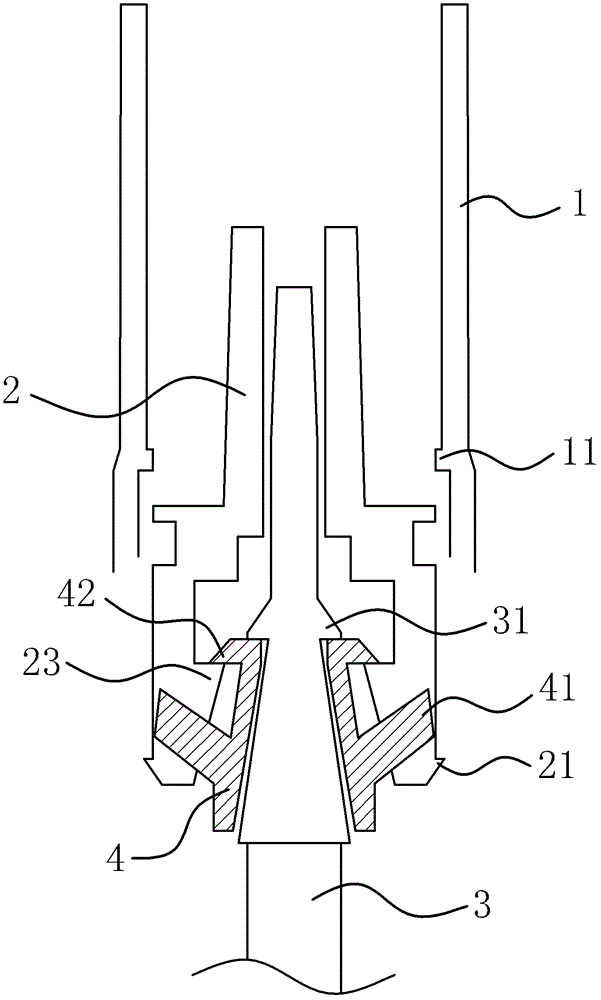

[0035] Such as figure 1 , figure 2 and image 3 The safety self-destructing syringe shown mainly includes a syringe 1, a needle seat 2 sealed inside the front end of the syringe 1 and a needle bar 3 inside the syringe 1, the front end of the needle bar 3 can be inserted into into the needle seat 2. Such as Figure 1-4 As shown, the inner side of the front end of the syringe 1 is provided with an annular step 11 capable of limiting the needle base 2 , and the needle base 2 has a limiting boss 21 which can abut against the inner surface of the annular step 11 .

[0036] Such as Figure 5 As shown, the needle holder 2 is located at one end of the limiting boss 21 and is provided with a plurality of locking grooves 22 along its axial direction. Such as figure 1 , figure 2 and image 3 As shown, the needle bar 3 is sleeved with a cylindrical elastic limiter 4, the side of the elastic limiter 4 has a number of elastic limiters 41 corresponding to the slot 22, the elastic l...

Embodiment 2

[0046] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that: Figure 8 and Figure 9 As shown, there are two elastic limiting parts 41 , the elastic limiting parts 41 are arranged symmetrically, and there are also two locking slots 22 , and the two elastic limiting parts 41 are respectively located in the locking slots 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com