White tea-withering machine

A technology of withering machine and white tea, applied in the field of white tea withering machine, can solve the problems of affecting work efficiency, long production time, increase labor cost, etc., and achieve the effects of reasonable structure design, shortening withering time, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

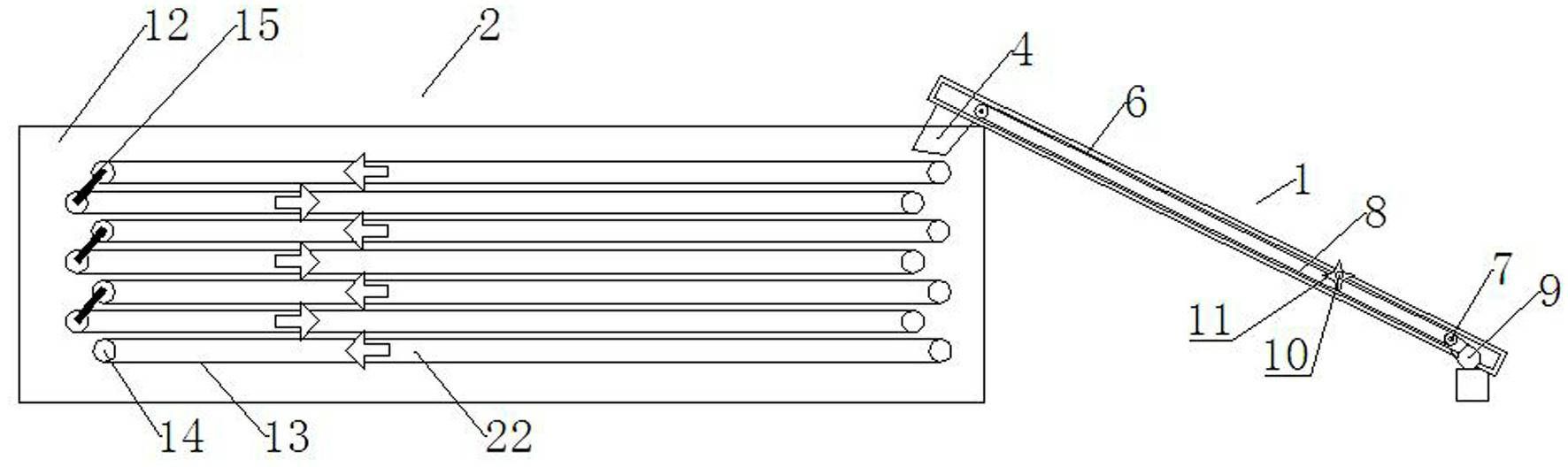

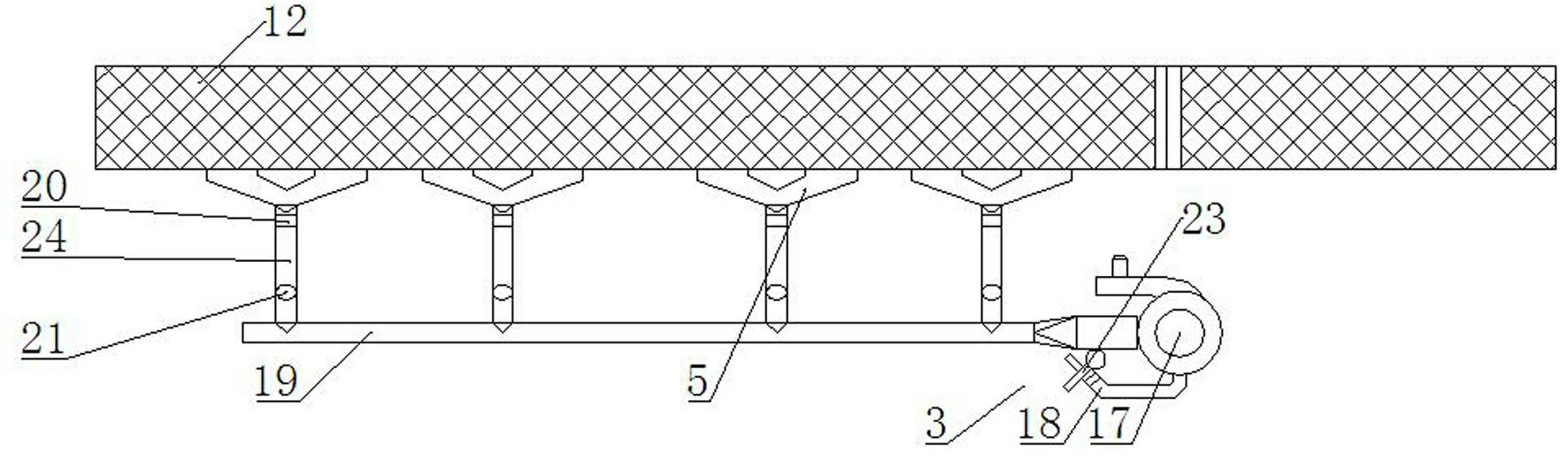

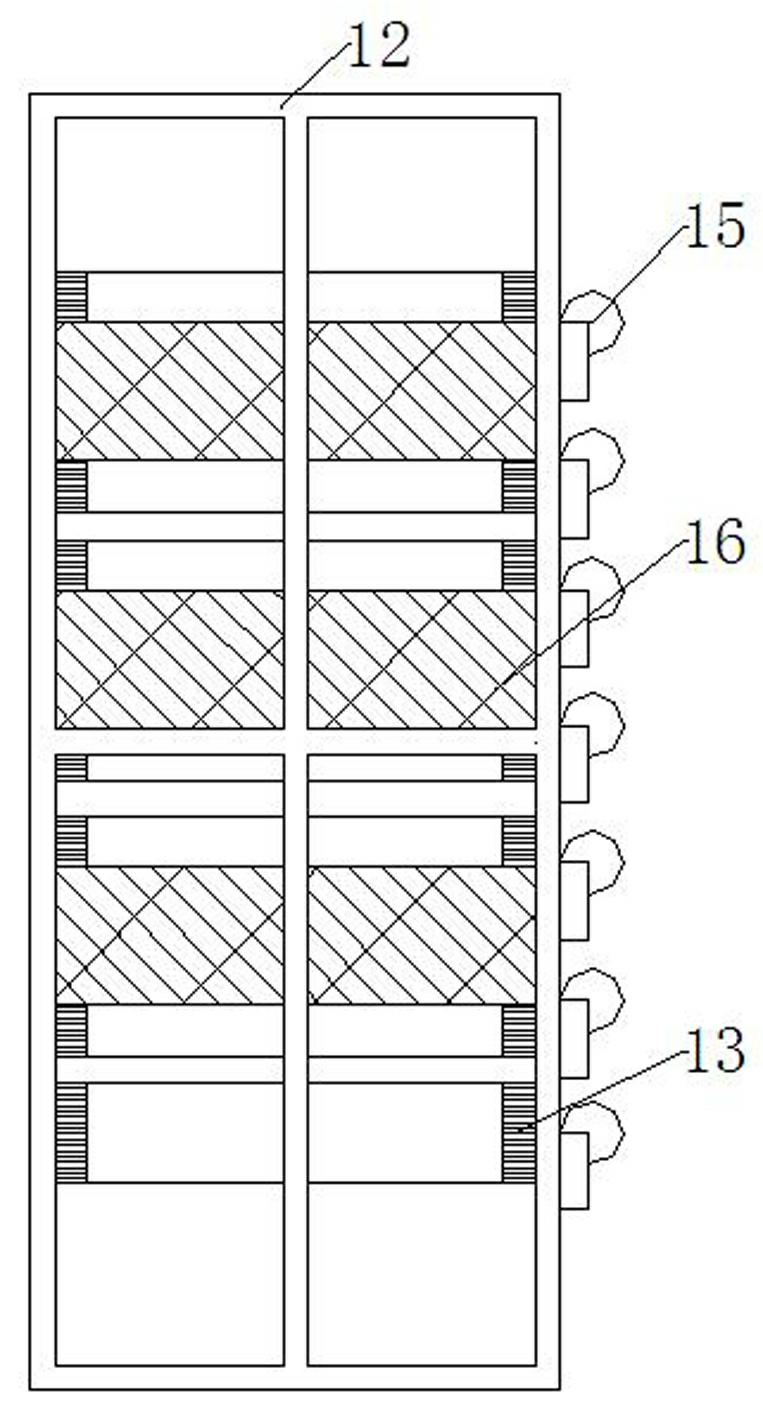

[0014] Such as figure 1 , figure 2 , image 3 As shown, a white tea withering machine is composed of a transmission device 1, a circulation device 2 and a temperature adjustment device 3. One end of the transmission device 1 is connected to the circulation device 2 through a feed hopper 4, and the temperature adjustment device 3 is heated through a branch circuit. The air pipe 5 is connected to the circulation device 2 . Described transmission device 1 comprises transmission frame 6, and described transmission frame 6 two ends are respectively provided with transmission shaft 7, and transmission shaft 7 at both ends is connected by transmission belt 8, wherein the transmission shaft 7 of one end is driven by motor 9, and the other end It is fixed on the circulation device 2, and a stirring shaft 10 is arranged in the middle of the transmission frame 6, and a stirring blade 11 is arranged on the stirring shaft 10. The circulation device 2 includes a circulation box 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com