Resin plug-hole apparatus of PCB back borehole and method thereof

A technology of resin plugging and back drilling, which is applied in the direction of electrical connection formation of printed components, etc., and can solve problems such as many stepped through holes, large air bubbles, and poor reliability of circuit boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

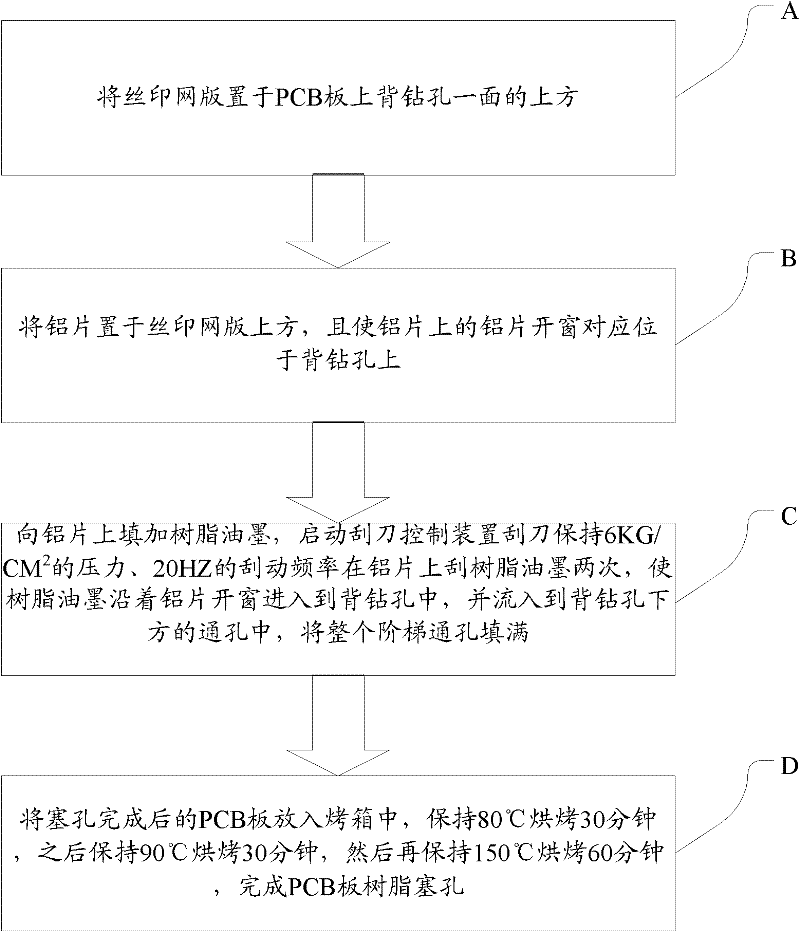

[0020] To illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] The invention provides a resin plug hole device and method for PCB back drilling. It is mainly used in the production of some current PCB boards. Due to the stepped through holes, the resin ink is relatively sparsely combined in the hole during the resin plugging process. As a result, more and larger bubbles are generated in the stepped through holes, which leads to the problem of poor reliability of the entire circuit board.

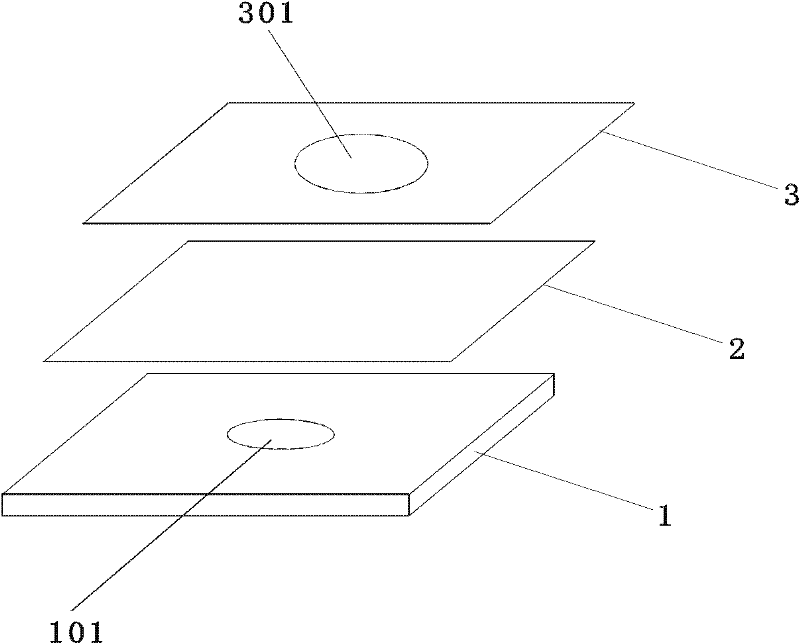

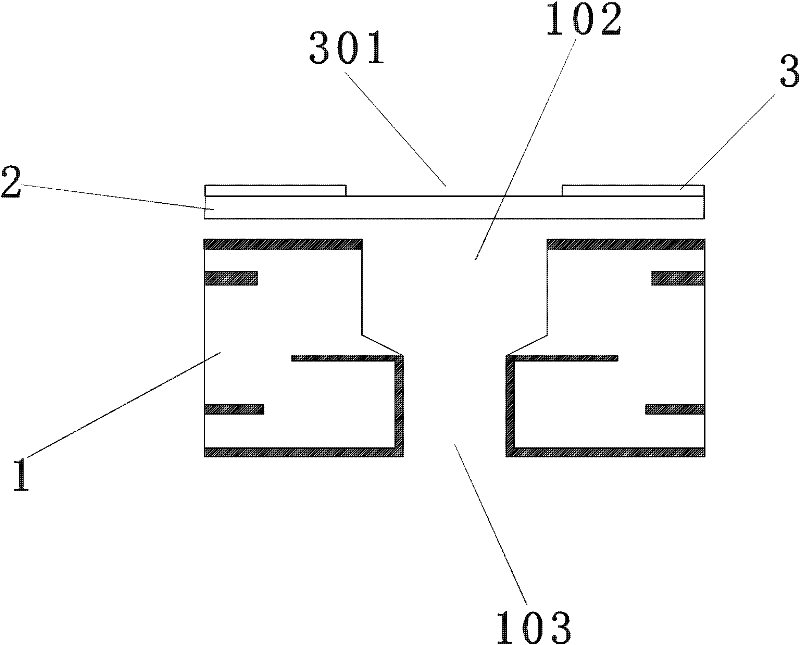

[0022] See figure 1 , figure 2 As shown, figure 1 It is a schematic diagram of the structure of the resin plug hole device for drilling the PCB back of the present invention; figure 2 for figure 1 Cutaway view. The resin plugging device for PCB back drilling of the present invention includes a PCB board 1, a screen printing screen 2 and an aluminum sheet 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com