Material torsion testing machine

A technology of torsion testing machine and driving column, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of high cost, poor test accuracy, large error, etc., and achieve the effect of eliminating cumulative error, good product quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

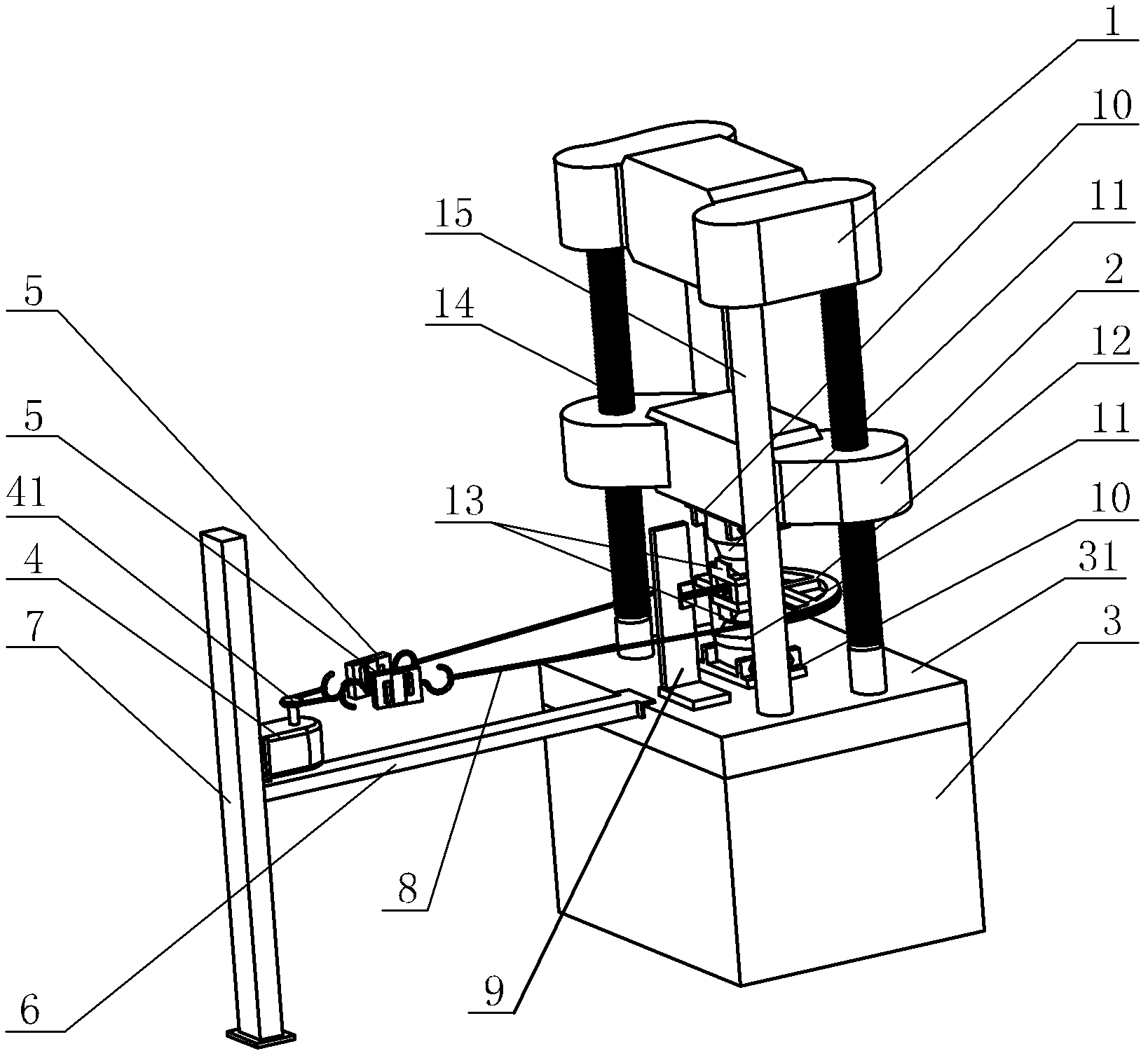

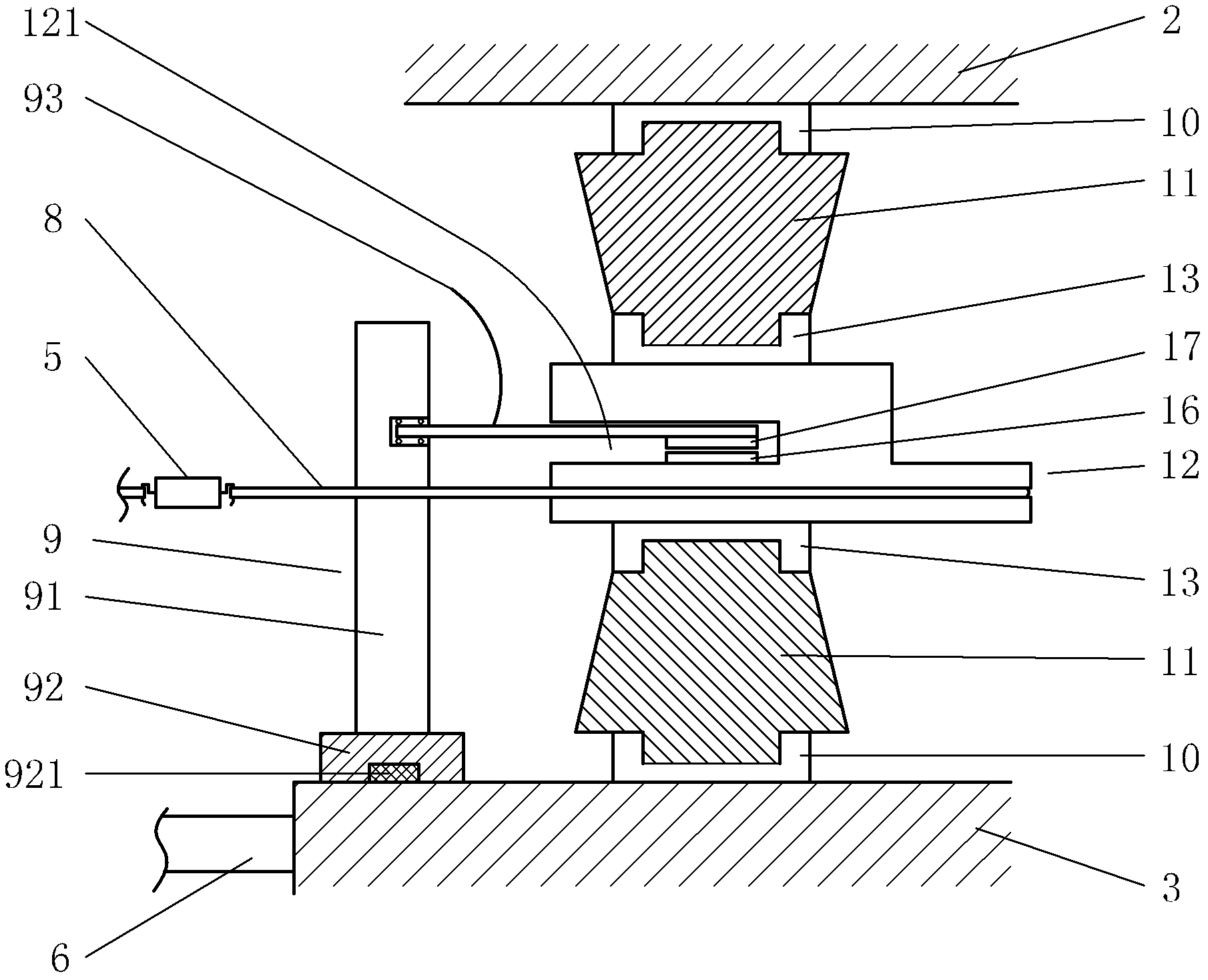

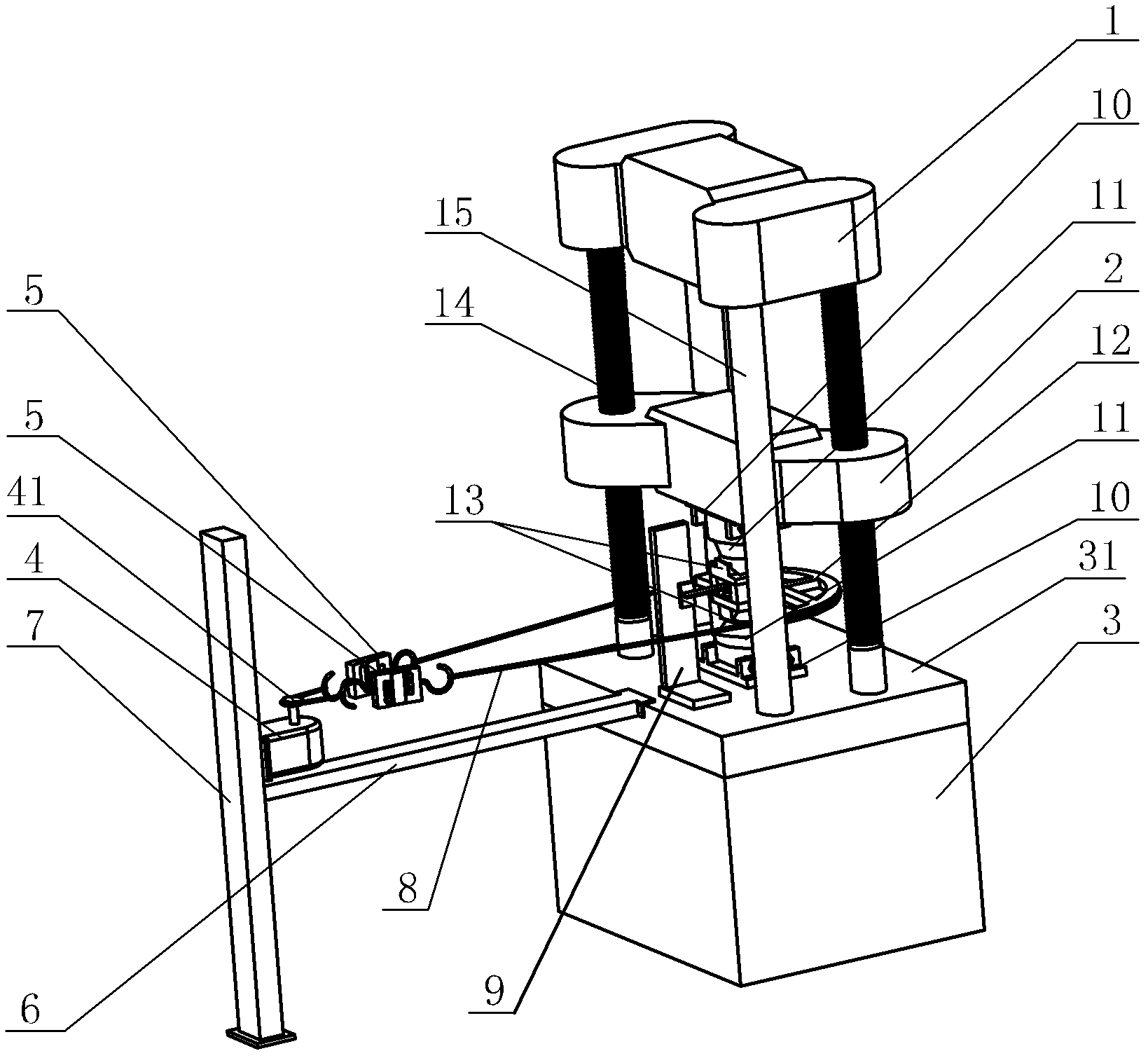

[0019] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 :

[0020] A material torsion testing machine, the base 3 is provided with a drive column 14 and a column 15, the drive column 14 and the column 15 are arranged parallel to each other and perpendicular to the upper table 31 of the base 3, the upper end of the column 15 is connected to the top beam 1, A movable beam 2 is arranged between the top beam 1 and the base 3, and the movable beam 2 is driven to move up and down by the driving column 14 driven by the power device. Fixing seats 10 for installing the workpiece 11 to be tested are respectively arranged on the surface, and a turntable 12 is arranged between the two fixing seats 10. The upper and lower ends of the turntable 12 are respectively provided with fixing positions 13 for installing the workpiece 11 to be tested. The middle parts of the two fixing positions 13 A sensor ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com