Visual inspection method of electron beam welding pool shape parameter

A technology of electron beam welding and shape parameters, which can be used in measurement devices, image data processing, instruments, etc., and can solve problems such as large noise interference and inability to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

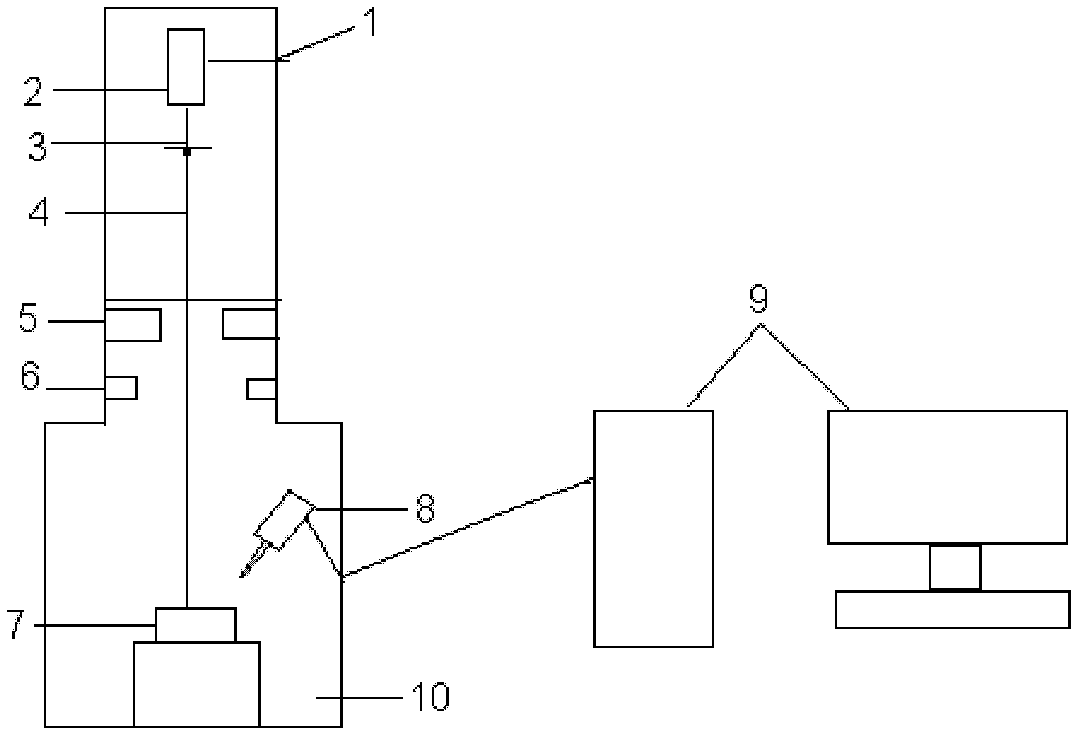

[0049] Specific Embodiment 1: The specific process of a visual inspection method for the shape parameter of the electron beam welding molten pool according to the present embodiment is as follows:

[0050] Step A, putting the workpiece to be welded into a vacuum chamber and fixing it;

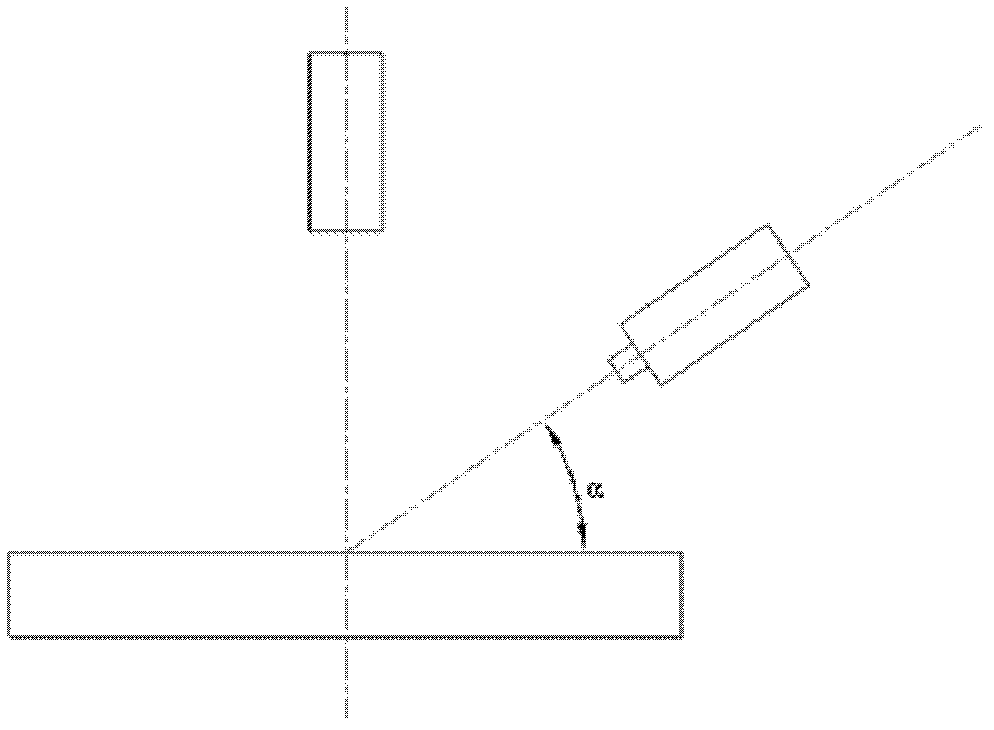

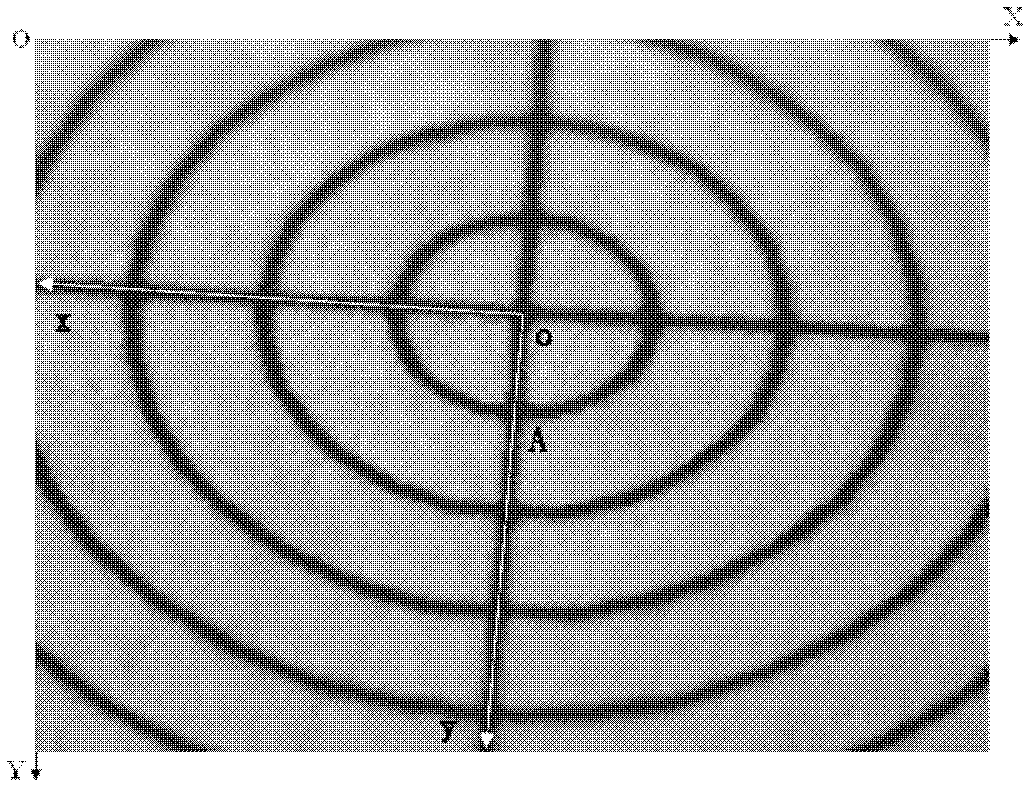

[0051]Step B. Start the camera in the vacuum chamber to calibrate the color molten pool image visual sensing system for electron beam welding: 1. The welding starting point on the surface of the welding workpiece is taken as the coordinate origin o, and the welding direction is the positive direction of the x-axis, which is perpendicular to the welding direction The following is the positive direction of the y-axis, establish the coordinate system oxy, which is the workpiece coordinate system; 2. Then draw a group of concentric circles with the workpiece coordinate system as the reference system. The radius of the smallest circle is 1 mm, and the radius of each concentric circle is The unit is ...

specific Embodiment approach 2

[0082] Embodiment 2: This embodiment differs from Embodiment 1 in that the structural elements described in step B include 2 to 5 pixels and 1 center point. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0083] Embodiment 3: The difference between this embodiment and Embodiments 1 to 2 is that the structural element B described in step B is in the shape of a disc, square, rhombus or hexagon. Others are the same as the specific embodiment 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com