Modularized steam waste pressure and waste heat power generation and balanced steam and heat supply system

A waste heat power generation and heating system technology, which is applied in steam applications, steam engine installations, machines/engines, etc., can solve problems such as the inability to solve the needs of different steam parameters of steam heat users and their matching problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

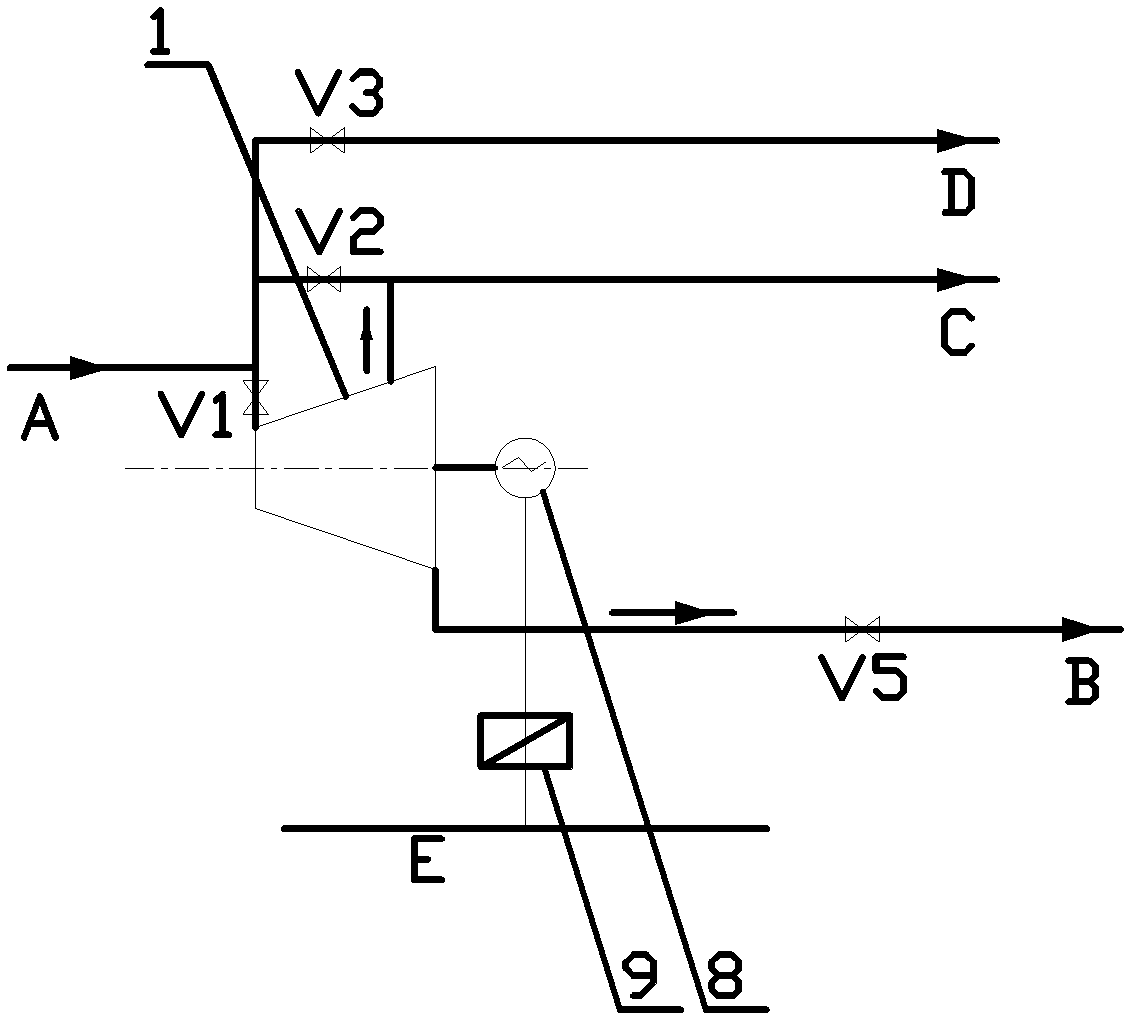

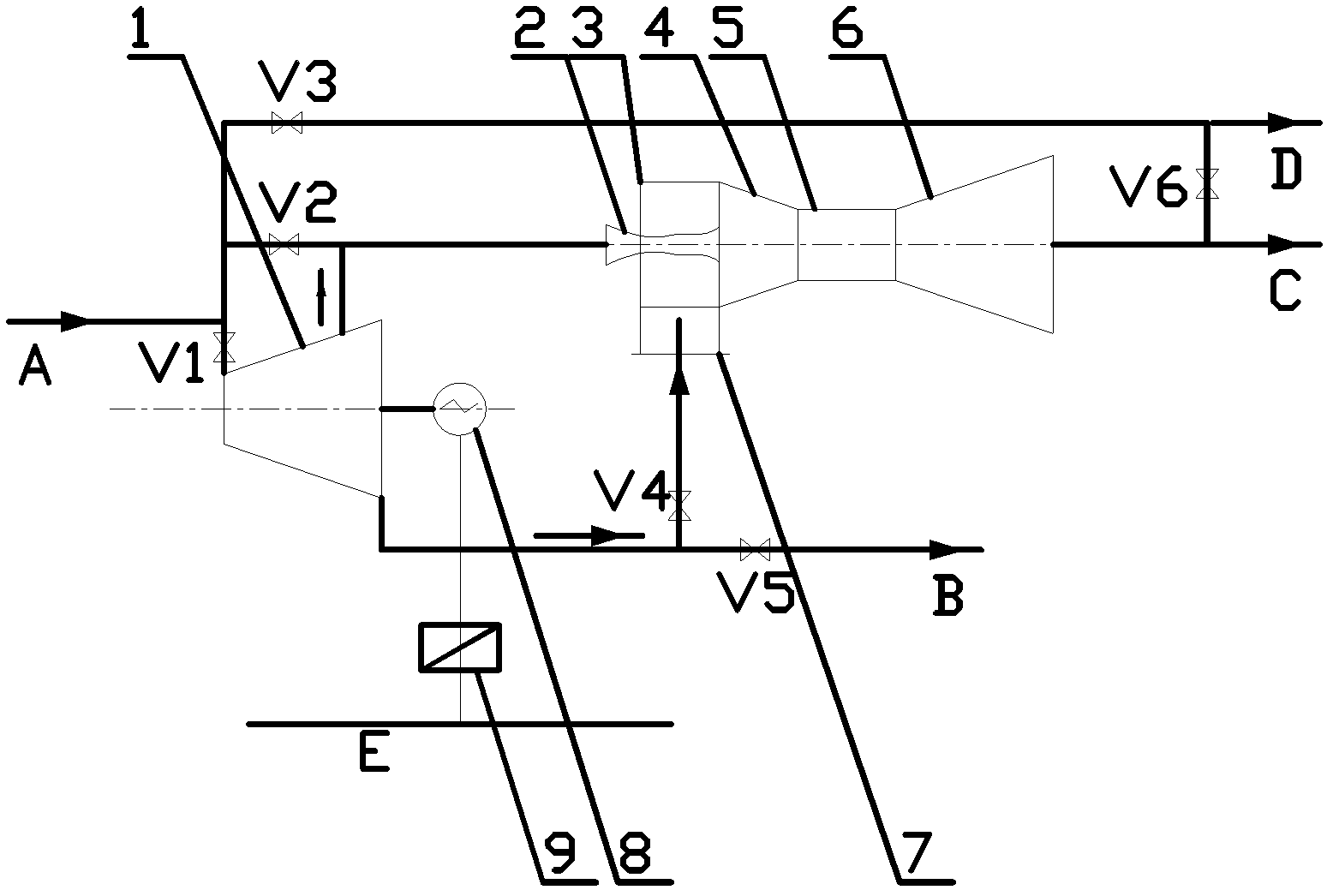

[0023] Embodiment 2 may also include a pipeline connecting the medium-pressure steam extraction port of the back-pressure steam turbine 1 with the inlet of the steam jet pump 3 driving the steam nozzle 2 .

[0024] The steam jet pump 3 of this embodiment can adopt a single-stage structure, which is mainly composed of a nozzle 2, an injection port 7, a mixing section 4, a throat 5, and a diffuser section 6. After the nozzle 2 is connected to the injection port 7 It is connected with the mixing section 4, the throat 5 and the diffuser section 6, and its nozzle 2 adopts an adjustable nozzle structure. It is also possible to adopt a multi-stage cascade structure with multiple stages connected in series and parallel to drive the fluid to do work in stages. Both the nozzle and the final injector are composed of an inlet section with a nozzle, a mixing section, a throat and a diffuser section connected in sequence (similar to the single-stage structure), and the final flow distributo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com