System for accurately controlling the rotation of excavation end of loader digger

A backhoe loader and control system technology, applied in mechanically driven excavators/dredgers, etc., can solve the problems of seal impact, inaccurate positioning, difficult control, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

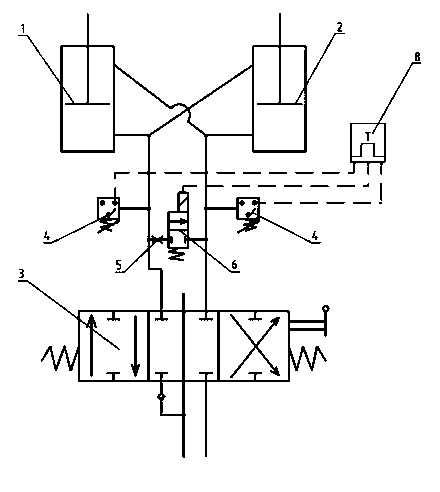

[0008] As shown in the figure, a backhoe loader digging end rotation precision control system includes a left cylinder 1, a right cylinder 2, a reversing valve 3, the small chamber of the left cylinder 1 and the large chamber of the right cylinder 2 connected, the large cavity of the left cylinder 1 is connected with the small cavity of the right cylinder 2, and the large chambers of the left cylinder 1 and the right cylinder 2 are respectively connected with the two reversing oil ports of the reversing valve 3, The large chamber oil circuits of the left oil cylinder 1 and the right oil cylinder 2 are respectively provided with a pressure switch 4, and the two oil circuits are connected by an oil circuit with a throttle valve 5 and a solenoid valve 6; the two pressure switches 4. Control the solenoid valve 6 through the delay relay 8 respectively. When the digging end turns back to the pointing position, the reversing valve 3 is operated to cut off the oil supply and return ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com