Method and device for optimizing naphtha

A technology of naphtha and raffinate, which is applied in the petroleum industry, naphtha processing, etc., can solve problems such as naphtha-free process flow, achieve the effects of reducing energy consumption, benefiting sustainable development, and improving the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

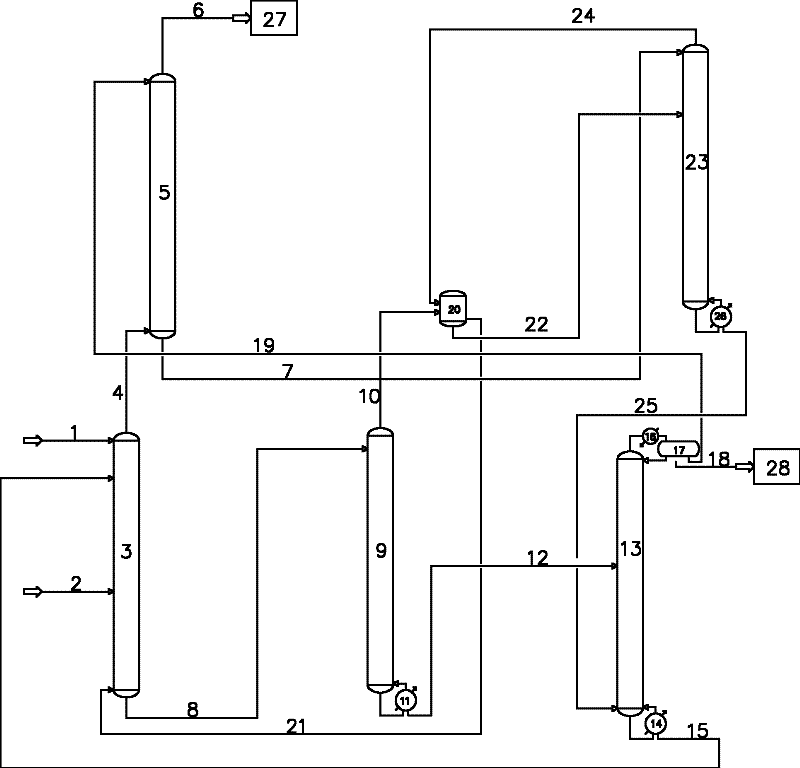

[0022] Below in conjunction with accompanying drawing, technology and equipment provided by the present invention are further described:

[0023] Through extraction and separation, the naphtha is divided into raffinate oil rich in alkanes and extract oil rich in naphthenes and aromatics; and then through water washing, stripping, rectification and other separation methods, the extract oil is separated from the extractant used . The separated and purified raffinate oil enters the ethylene cracking unit as a high-quality cracking raw material, and the extracted oil enters the catalytic reforming unit as a high-quality reforming raw material. The process flow includes: extraction tower, water washing tower, stripping tower, water fractionation tower and recovery tower. Technology, recovery of extractant, and recycling.

[0024] For the sake of clarity, this example uses a mixed solvent prepared from sulfolane and toluene as the extraction agent, the ratio range is 2:1 to 20:1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com