Formaldehyde-free cementing compound for profiled artificial board and preparation method thereof

A technology of wood-based panels and adhesives, which is applied in manufacturing tools, joining of wooden veneers, polyurea/polyurethane coatings, etc., can solve problems such as insufficient bonding strength and rebound performance, increase manufacturing costs, and affect product quality. Guaranteed resilience performance, reduced scrap rate, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

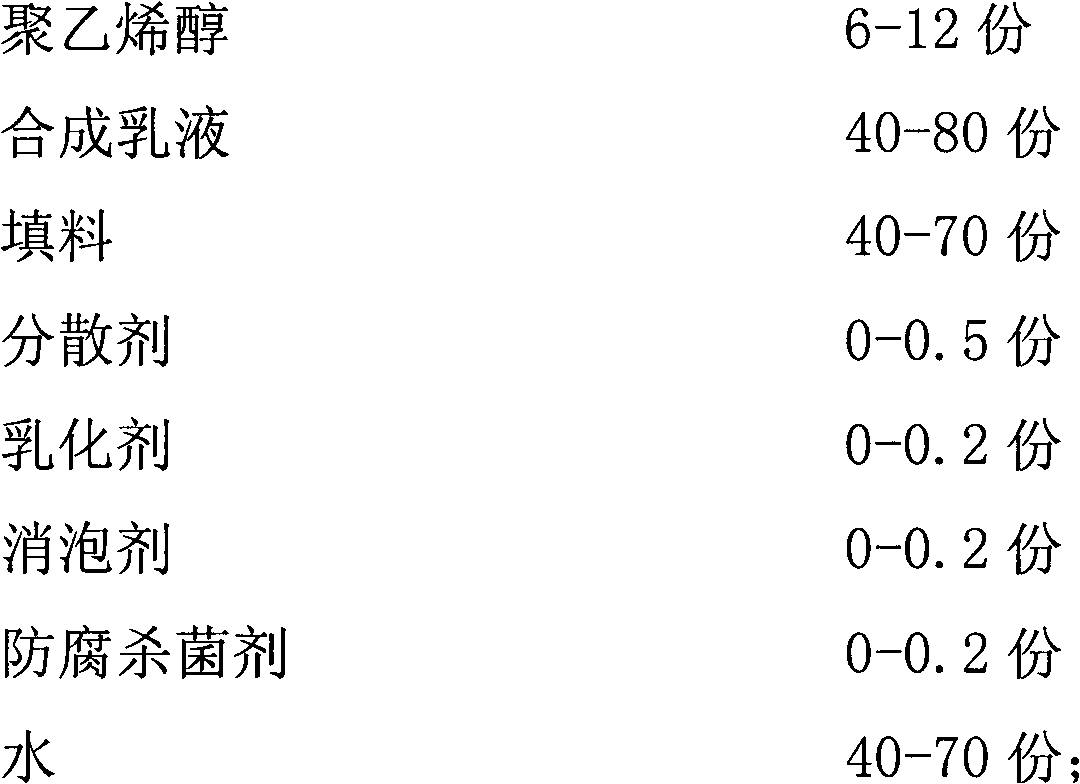

[0023] A formaldehyde-free adhesive for special-shaped wood-based panels, including A component and B component, A component is formed by mixing the following components by weight:

[0024]

[0025] Component B is isocyanate; wherein, component A: component B = 100 parts: 8-20 parts.

[0026] Wherein, the polyvinyl alcohol can be selected from one of PVA1788, PVA1799, PVA2088, PVA2099, PVA2288, PVA2299, PVA2488, PVA2499 or a mixture of two or more. Polyvinyl alcohol is preferably one or a mixture of PVA1788, PVA2088, and PVA2488;

[0027] The filler is preferably ground calcium carbonate;

[0028] The emulsifiers are preferably sodium lauryl sulfate, sodium dodecylbenzenesulfonate, octylphenol polyoxyethylene ether OP series;

[0029] Defoamers are preferably non-ionic silicones and mineral oils;

[0030] Antiseptic and fungicides are preferably sorbates and isothiazolinones;

[0031] The isocyanate is preferably polyphenylpolymethylene polyisocyanate.

[0032] Applied...

Embodiment 2

[0041] A formaldehyde-free adhesive for special-shaped wood-based panels, including A component and B component, A component is formed by mixing the following components by weight:

[0042]

[0043] Component B is isocyanate; wherein, component A: component B = 100 parts: 8-20 parts.

[0044] Applied to specific components, the implementation results are as follows:

[0045] Add 585kg of water to a 2t reactor equipped with a stirring device. After heating to 40°C, slowly add 110kg of polyvinyl alcohol while heating. When the temperature rises above 90°C, the polyvinyl alcohol is completely dissolved, then stop heating and keep it warm for 1h. ; Cool down to 50°C; Add 400kg of polyvinyl acetate-ethylene emulsion, 400kg of acrylic acid emulsion, 20kg of 20% sodium hexametaphosphate solution, 20kg of 10% OP-10 solution, and 2kg of non-ionic mineral oil defoamer , add 2kg of potassium sorbate, stir and mix for 10-15min; add 500kg of heavy calcium carbonate, disperse at high sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com