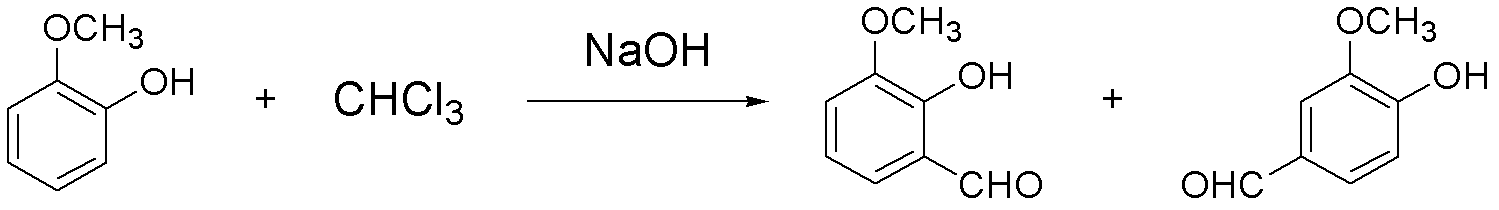

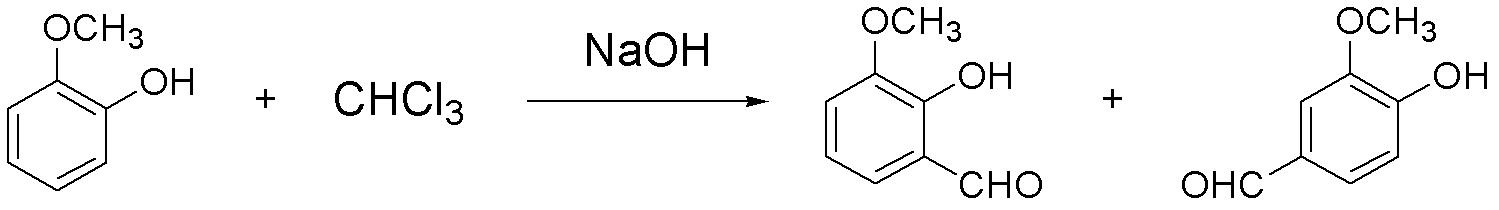

Method for preparing mixture of ortho vanillin and vanillin

An ortho-vanillin and mixture technology, applied in the field of pharmaceutical synthesis, can solve the problems of low reaction conversion rate, low vanillin content, unsuitable for industrial production and the like, and achieve the effect of high weight yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1. Reaction operation method

[0012] 100 grams of guaiacol, 480 milliliters of methanol, and 66 milliliters of chloroform were added to a 1-liter four-necked flask to obtain a mixed solution, which was stirred and heated to 50° C.; the prepared aqueous sodium hydroxide solution (130 grams of sodium hydroxide (dissolved in 160 ml of water) was slowly added dropwise to the mixed solution, the reaction temperature was controlled at about 55°C, and the dropping process was about 1 hour; PH to 6, filter with suction, wash the filter cake with recovered methanol until it is colorless, and combine the washing liquid and the filtrate.

[0013] 2. Steam methanol

[0014] 40°C water pump decompression distillation evaporated methanol to dryness, layered to separate the upper layer of oil; after washing with water, separated into layers, and separated the oil layer; 60°C diaphragm pump decompressed distillation for 30 minutes, finally obtained oily liquid, weighed, and the ortho...

Embodiment 2

[0018] 1. Reaction operation method

[0019] 80 grams of guaiacol, 400 milliliters of methanol, and 40 milliliters of chloroform were added to a 1-liter four-necked flask to obtain a mixed solution, which was stirred and heated to 50° C.; the prepared aqueous sodium hydroxide solution (100 grams of sodium hydroxide (dissolved in 160 ml of water) was slowly added dropwise to the mixed solution, the reaction temperature was controlled at about 55°C, and the dropping process was about 1 hour; PH to 6, filter with suction, wash the filter cake with recovered methanol until it is colorless, and combine the washing liquid and the filtrate.

[0020] 2. Steam methanol

[0021] 40 ℃ water pump decompression distillation to evaporate methanol to dryness, separate the upper oil layer by layer; separate the layers after washing with water, and separate the oil layer. 60 DEG C diaphragm pump vacuum distillation for 30 minutes, finally obtained oily liquid, weighed, and the total weight y...

Embodiment 3

[0025] 1. Reaction operation method

[0026] 120 grams of guaiacol, 560 milliliters of methanol, and 90 milliliters of chloroform were added to a 1-liter four-neck flask to obtain a mixed solution, which was stirred and heated to 50° C.; the prepared aqueous sodium hydroxide solution (160 grams of sodium hydroxide (dissolved in 160 ml of water) was slowly added dropwise to the mixed solution, the reaction temperature was controlled at about 55°C, and the dropping process was about 1 hour; PH to 6, filter with suction, wash the filter cake with recovered methanol until it is colorless, and combine the washing liquid and the filtrate.

[0027] 2. Steam methanol

[0028] 40°C water pump decompression distillation evaporated methanol to dryness, layered to separate the upper layer of oil; after washing with water, separated into layers, and separated the oil layer; 60°C diaphragm pump decompressed distillation for 30 minutes, finally obtained oily liquid, weighed, and the ortho p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com