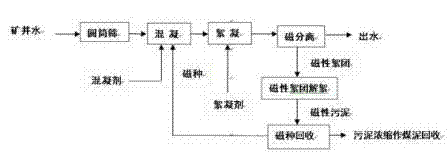

Treatment process for mine water of coal deep well

A treatment process and technology for mine water, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unreasonable underground mine water treatment, complicated equipment and operation process, and low service life, so as to achieve a small footprint and use The effect of long life and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The site of a coal deep mine water purification treatment project, with a treatment scale of 6000m3 / d. Utilize the technical scheme described in claim 7 of the present invention to process, and the cylindrical sieve screen mesh is 1mm; The high-speed stirring speed is 3000r / min; The equipment used is a drum magnetic separator with a magnetic field strength of 2500Gs; the magnetic separator used in the magnetic separation process is a magnetic disk structure.

[0028] The specific experimental conditions are as follows:

[0029] The influent SS is 505.4mg / L, the effluent SS is 8.6mg / L, and the removal rate is 98.3%. When the influent turbidity is 610NUT, the effluent turbidity is 8NTU, and the removal rate is 98.6%. When the influent TP is 0.625mg / L, the effluent TP is 0.087mg / L, and the removal rate is 86.1%. The influent COD is 127mg / L, the effluent COD is 47mg / L, and the removal rate is 63%. The yield of sludge was 0.1%, and the recovery rate of magnetic seeds was...

Embodiment 2

[0031] The site of a deep mine water purification treatment project in a coal mine, with a treatment scale of 10,000m3 / d. Utilize the technical scheme of claim 8 of the present invention to process, the cylindrical sieve screen is 5mm; the high-speed stirring speed is 1500r / min; the magnetic seed is a magnetic iron mineral, and its particle diameter is at 0.03mm; the equipment used in the magnetic seed recovery process is Drum type magnetic separator, the magnetic field strength is 4000Gs; the magnetic separator used in the magnetic separation process is a magnetic disk structure.

[0032] The specific experimental conditions are as follows:

[0033] The influent SS is 494mg / L, the effluent SS is 6.0mg / L, and the removal rate is 98.7%. When the influent turbidity is 532NUT, the effluent turbidity is 6.6NTU, and the removal rate is 98.8%. When the influent TP is 0.17mg / L, the effluent TP is 0.013mg / L, and the removal rate is 92.4%. The influent COD is 54mg / L, the effluent CO...

Embodiment 3

[0035] The test site of deep mine water purification treatment in a coal mine, with a treatment scale of 1400m3 / d. Utilize the technical scheme of claim 8 of the present invention to process, and the cylindrical sieve screen mesh is 3mm; The high-speed stirring speed is 2000r / min; The magnetic seed is a magnetic iron mineral, and its particle diameter is at 0.15mm; The equipment used in the magnetic seed recovery process is Drum type magnetic separator, the magnetic field strength is 3000Gs; the magnetic separator used in the magnetic separation process is a magnetic disk structure.

[0036] The specific experimental conditions are as follows:

[0037] When the influent SS is 604.7mg / L, the effluent SS is 14.2mg / L, and the removal rate is 97.6%. When the influent TP is 0.705mg / L, the effluent TP is 0.108mg / L, and the removal rate is 97.1%. The influent COD is 56.7, the effluent COD is 23.2, and the removal rate is 58.2%. The yield of sludge was 0.2%, and the recovery rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com