Automatic control method for evaporation treatment of wet flue gas desulphurization wastewater

A wet flue gas desulfurization and desulfurization wastewater technology, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Affecting the effect of flue gas desulfurization and other issues to achieve the effect of improving reliability, improving operating efficiency, and reducing malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

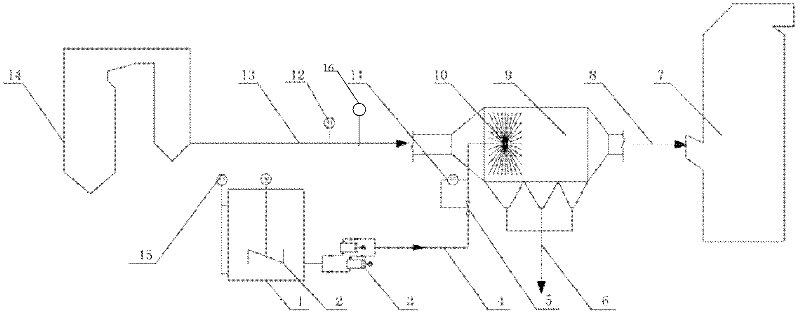

[0026] Such as figure 1 The waste water evaporation treatment process comprises a waste water tank 1, a waste water metering pump 3 connected to the waste water tank 1, a waste water pipe 4 drawn from the waste water metering pump 3, an atomizing nozzle 10 communicated with the waste water pipe 4, and a dedusting device for accommodating the atomizing nozzle 10 9, the flue gas channel 13 connected to the inlet of the dust collector 9 for inputting boiler flue gas, the desulfurization absorption tower 7 connected to the outlet of the dust collector 9 and the precipitated solid conveying pipeline 5 connected to the dust collector 9, and the flue gas channel 13 An air preheater 16 is set above, the boiler flue gas is provided by the boiler 14, and the dust collector 9 is an electric dust collector.

[0027] The waste water pipe 4 is provided with a nozzle regulating valve 5, and the pipe from the nozzle regulating valve 5 to the atomizing nozzle 10 is provided with a pressure mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com