Biological template based preparation method for magnetic photonic crystals

A technology of photonic crystals and biological templates, applied in the field of materials science, can solve the problems that limit the theoretical research and application of magneto-optical devices, and achieve the effects of good controllability, simple process, and improved response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

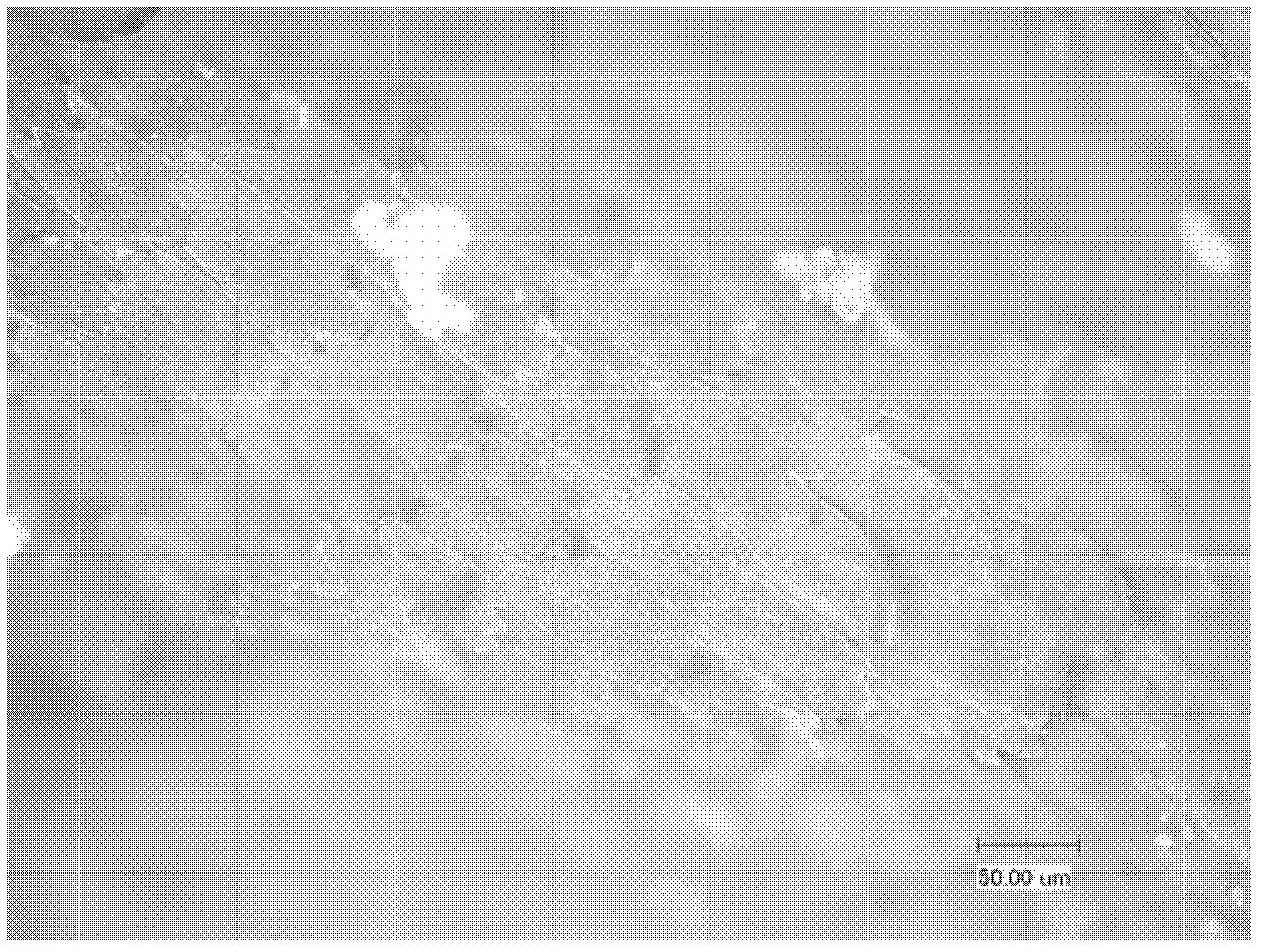

Image

Examples

Embodiment 1

[0027] In the first step, put butterfly wings into 40wt% CH 3 After 4 hours in the COOH solution, the minerals that are not easy to be removed by sintering are dissolved, and then rinsed with distilled water and dried for later use.

[0028] The second step is the preparation of the precursor solution. FeCl 3 The preparation scheme of the solution: under the condition of a hot water bath, prepare a ferric chloride ethanol solution with a concentration of 0.1mol / L.

[0029] The third step is to soak the processed butterfly wings in the prepared precursor solution for 12 hours

[0030] In the fourth step, after soaking, take out the sample, rinse it with distilled water, and then put it into an oven for drying at a temperature range of 50°C for 10 hours. After drying, sintering at a temperature of 450°C to remove the biological template to obtain a functional material of ferric oxide with a photonic crystal structure of the biological template;

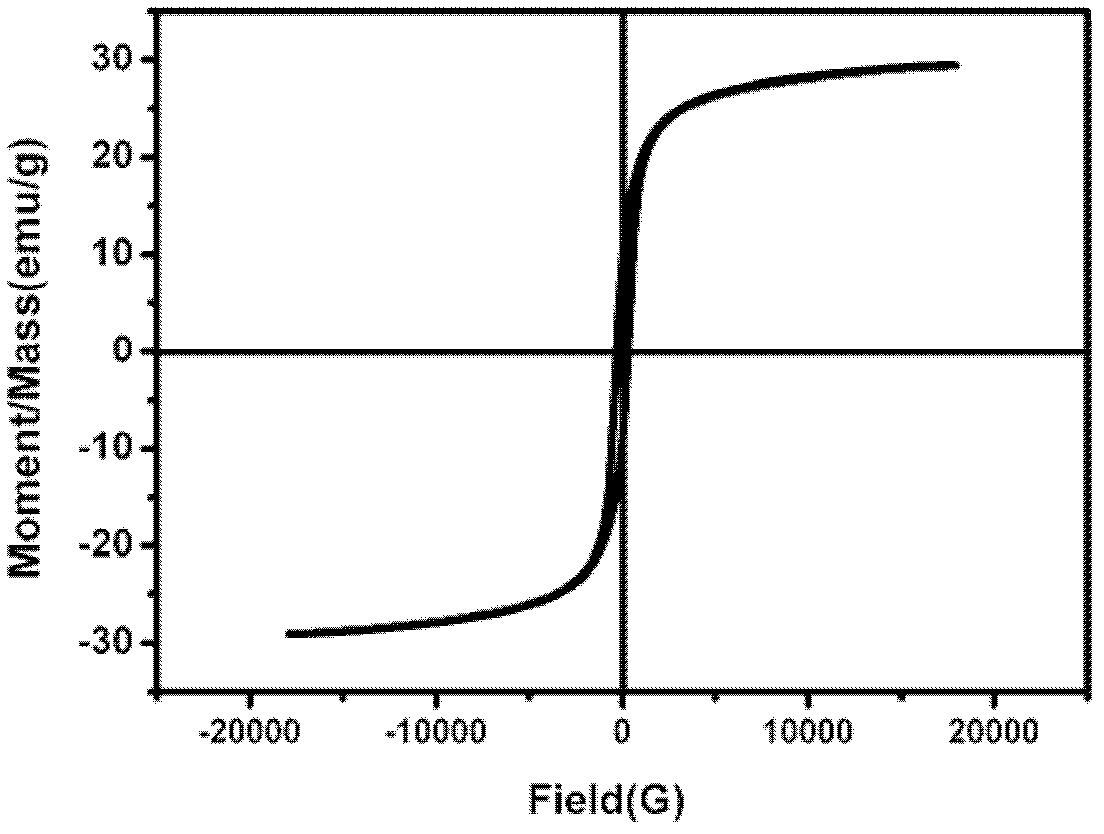

[0031] In the fifth step, th...

Embodiment 2

[0036] In the first step, put butterfly wings into 40wt% CH 3 After 4 hours in the COOH solution, the minerals that are not easy to be removed by sintering are dissolved, and then rinsed with distilled water and dried for later use.

[0037] The second step is the preparation of the precursor solution. FeCl 3 The preparation scheme of the solution: under the condition of a hot water bath, prepare a ferric chloride ethanol solution with a concentration of 0.1mol / L.

[0038] The third step is to soak the processed butterfly wings in the prepared precursor solution for 20 hours

[0039] In the fourth step, after soaking, take out the sample, rinse it with distilled water, and then put it into an oven to dry at a temperature range of 60°C for 10 hours. After drying, sintering at a temperature of 500°C to remove the biological template to obtain a functional material of ferric oxide with a photonic crystal structure of the biological template;

[0040]In the fifth step, the abo...

Embodiment 3

[0042] In the first step, put butterfly wings into 40wt% CH 3 After 4 hours in the COOH solution, the minerals that are not easy to be removed by sintering are dissolved, and then rinsed with distilled water and dried for later use.

[0043] The second step is the preparation of the precursor solution. FeCl 3 Solution preparation scheme: under the condition of hot water bath, prepare ferric chloride ethanol solution with a concentration of 1mol / L.

[0044] The third step is to soak the processed butterfly wings in the prepared precursor solution for 48 hours

[0045] In the fourth step, after soaking, take out the sample, rinse it with distilled water, and then put it into an oven to dry at a temperature range of 80°C for 10 hours. After drying, sintering at a temperature of 800°C to remove the biological template to obtain a functional material of ferric oxide with a photonic crystal structure of the biological template;

[0046] In the fifth step, the above-mentioned pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com