Packing material capable of improving humidity resistance of frozen drinks and production method of packing material

A packaging material and production method technology, applied in the field of packaging, can solve the problems of biscuits not being brittle, poor moisture-proof effect, etc., and achieve the effect of beautiful surface printing, improved grade, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

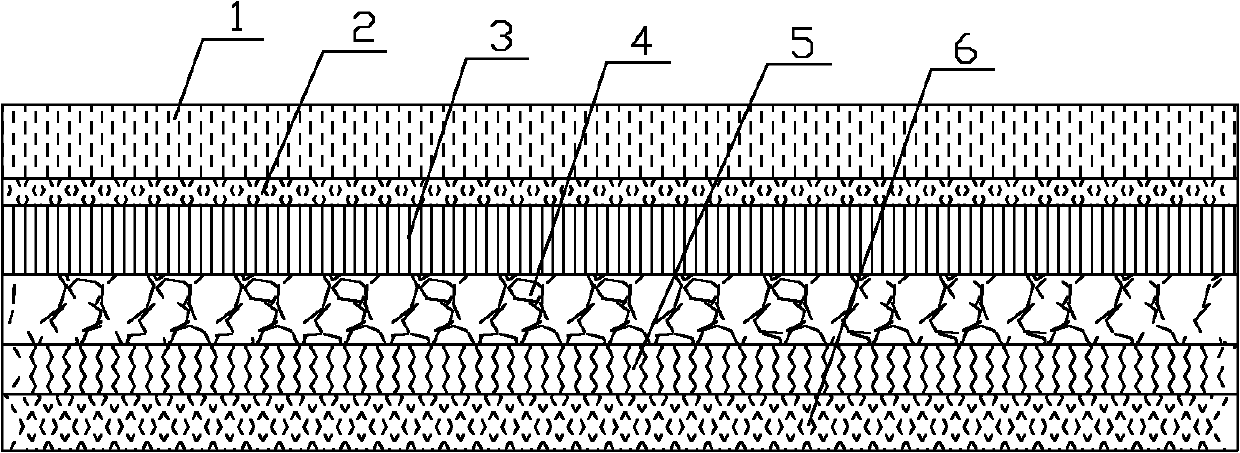

[0046] The packaging material consists of aluminum film 2, polyethylene resin adhesive layer 3, and 60 g / m 2 Food grade kraft paper 4 and 12 g / m 2 Polyethylene film 6 composition.

Embodiment 2

[0048] The packaging material consists of aluminum film 2, polypropylene resin adhesive layer 3, and 65 g / m 2 Food grade kraft paper 4 and 13 g / m 2 Polyethylene film 6 composition.

Embodiment 3

[0050] The packaging material consists of aluminum film 2, polyvinyl chloride resin adhesive layer 3, and 70 g / m 2 Food grade kraft paper 4 and 14 g / m 2 Polyethylene film 6 composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com