Technical method for constructing reference surface of assembled folio cartridge receiver and special clamp

A technology for opening the case and establishing a benchmark, which is applied in the field of mechanical processing, and can solve problems such as secondary clamping errors, low processing efficiency, and mass production restrictions, and achieve the effects of low manufacturing cost, high processing efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Describe the present invention below in conjunction with specific embodiment:

[0027] The present embodiment is aimed at processing the ring wool of the opening case.

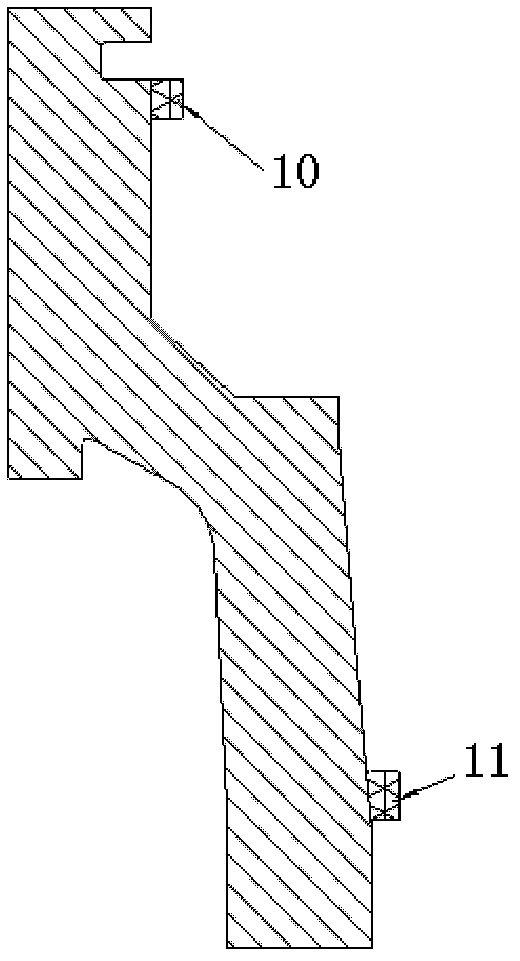

[0028] Step 1: Carry out rough turning processing on the ring wool of the opening case, and leave a circle of process reference blocks with an axial width of 12mm on the outer surface of the ring wool close to both ends of the ring wool; then mill the two circles of process reference blocks Groove processing, two flanges with a thickness of 20mm in the circumferential direction are left after the groove milling of each process reference block, such as figure 2 As shown, the axial centerlines of the four flange sides are in the same plane, and the plane passes through the central axis of the ring wool. image 3 A cross-sectional view of one side of the casing ring obtained after processing is given, in which the front flange edge 10 is the remaining flange edge after milling grooves of a process refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com