Method for controlling movement of knee joints of artificial limbs

A control method and knee joint technology, applied in the field of prosthetic knee joints, can solve problems such as acquisition methods, complicated problems, and lack of multi-axis prosthetic knee angle information, so as to avoid easy wear, simplify detection difficulty, and eliminate multi-valued problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The situation of the wearer of the prosthesis belt of the four-link above-the-knee prosthesis knee joint is: male, 23 years old, with a height of 170cm and a weight of 62kg, who has worn the prosthetic knee joint for 3 years.

[0037] The method for controlling the motion of the prosthetic knee joint of the prosthetic wearer, the steps are as follows:

[0038] The first step is to install the control parts of the prosthetic knee joint

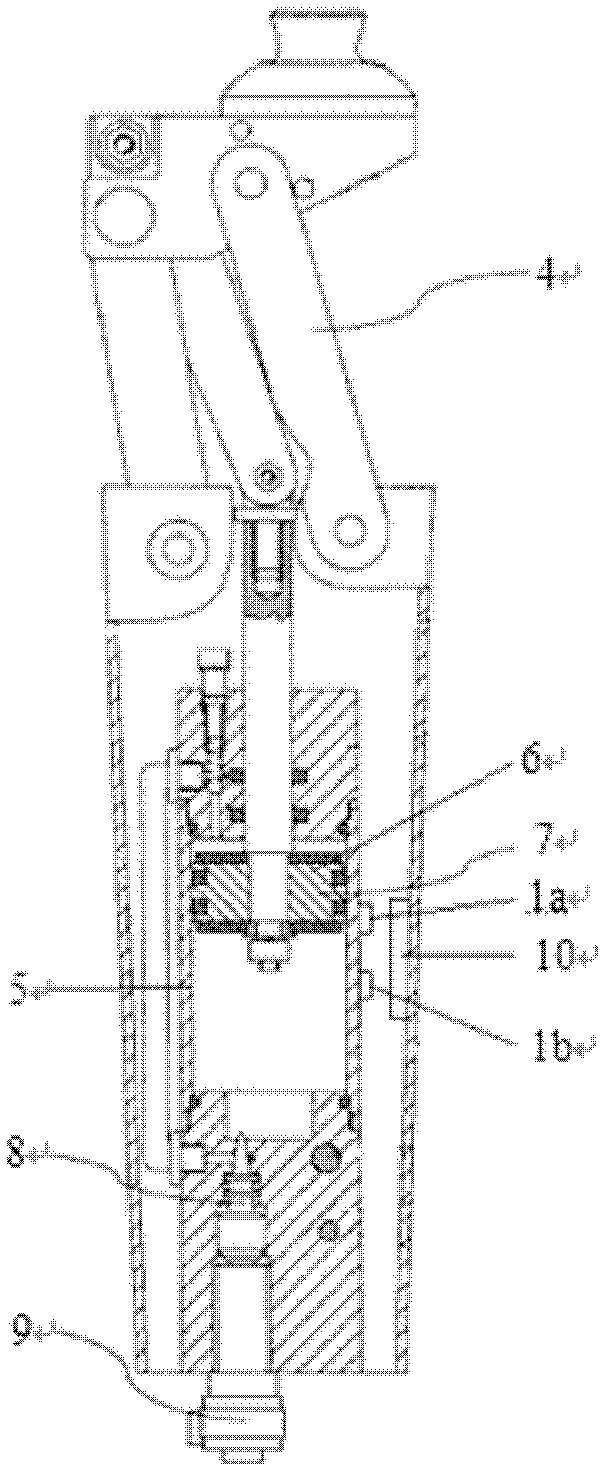

[0039] The structure of the knee joint body of the four-link upper knee prosthesis used is as above figure 2 The illustrated embodiment includes a four-bar linkage mechanism 4 , a cylinder block 5 , a cylinder piston 6 , a magnet 7 embedded in the cylinder piston, an air cavity needle valve 8 , a stepping motor 9 and a microcontroller 10 .

[0040] The four-link over-the-knee prosthetic knee joint body is installed on the limb of the prosthetic wearer according to known methods, and the walking speed and current step of the prosthetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com