Collector for bipolar lithium ion secondary battery

A secondary battery and current collector technology, applied in secondary batteries, secondary battery manufacturing, large flat batteries/batteries, etc., can solve the problem of reduced output power, unfavorable battery space, reduced battery output power density, and energy density, etc. problems, to achieve the effect of preventing penetration and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105]

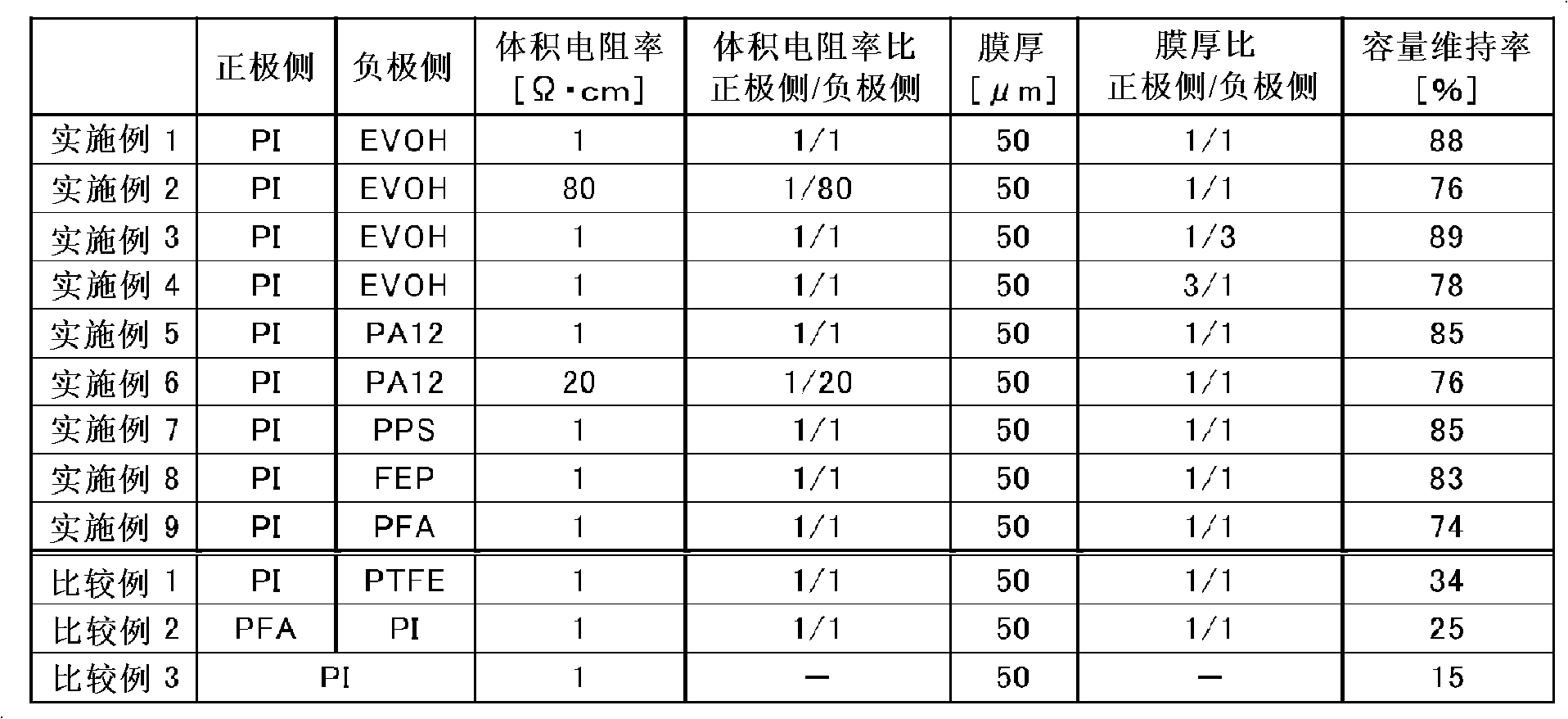

[0106] As a 1st electroconductive layer, the electroconductive resin film (film thickness: 25 micrometers) which mixed 10 mass % of ketjen blacks to 100 mass % of polyimide (PI) was prepared.

[0107] On the other hand, 10% by mass of Ketjen Black was mixed with 100% by mass of ethylene-vinyl alcohol copolymer (ethylene composition: 38 mol%) (EVOH) just melted, and a conductive resin film (film thickness: 25 μm), as the second conductive layer.

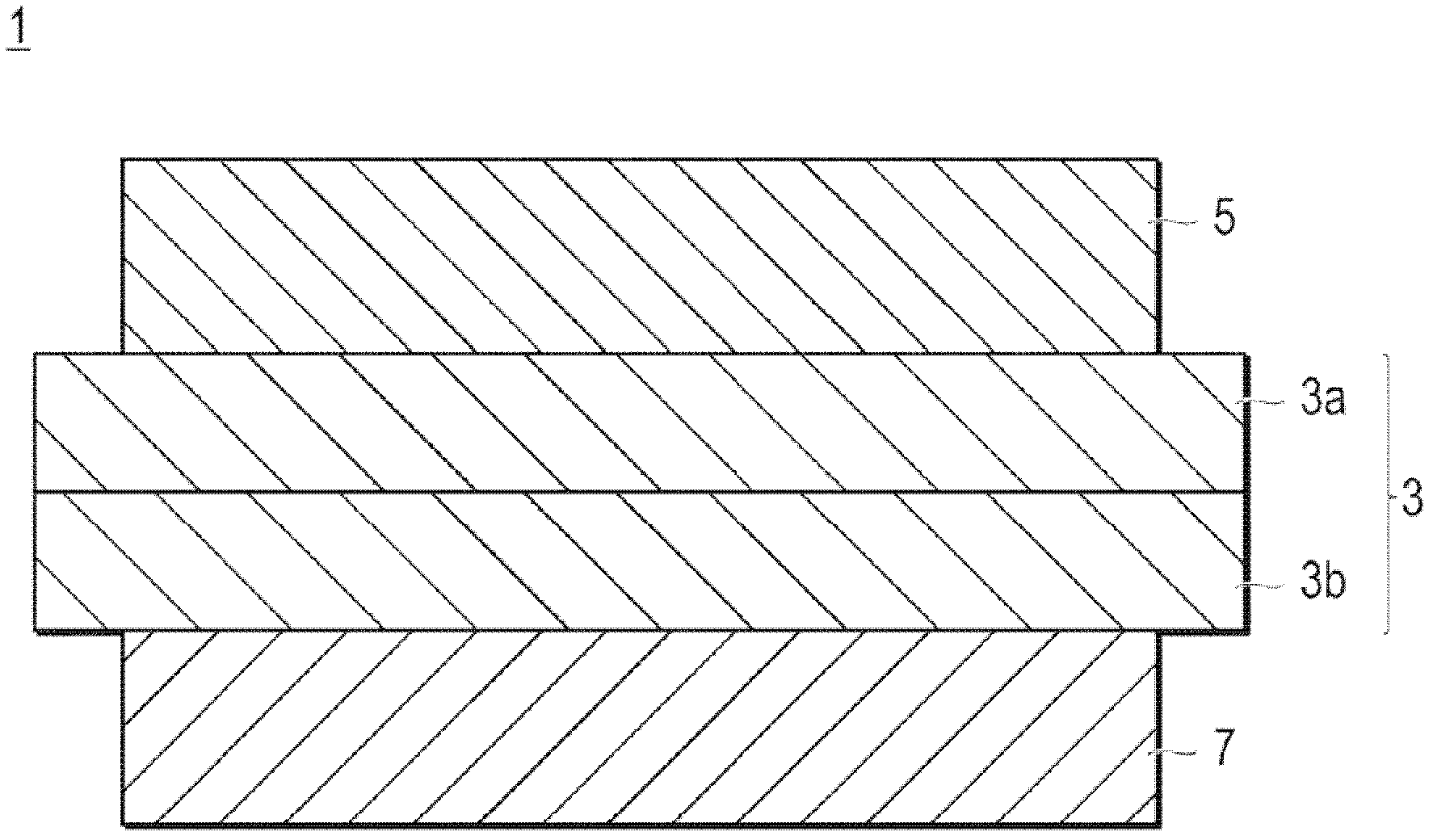

[0108] The first conductive layer and the second conductive layer prepared and fabricated as described above were stacked and heat-sealed at 160° C. for 10 minutes to fabricate a current collector for a bipolar lithium ion secondary battery having a two-layer structure.

[0109]

[0110] LiMn mixed as positive electrode active material 2 o 4 85% by mass, 5% by mass of acetylene black as a conductive additive, 10% by mass of polyvinylidene fluoride (PVDF) as a binder, and an appropriate amount of N-methyl-2-pyrrolidone ...

Embodiment 2

[0121] A bipolar secondary battery was produced in the same manner as in Example 1 above, except that the blending amount of Ketjen Black was 5% by mass relative to 100% by mass of EVOH when producing the second conductive layer.

Embodiment 3

[0123] As the first conductive layer, a material with a film thickness of 12.5 μm was used, and the second conductive layer was produced so as to have a film thickness of 37.5 μm. By the same method as in the above-mentioned Example 1, a Bipolar secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com