Power generating device by waste heat of automobiles

A technology for waste heat power generation and automobiles, which is applied to generators/motors, electrical components, engine components, etc., and can solve problems such as low hysteresis characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

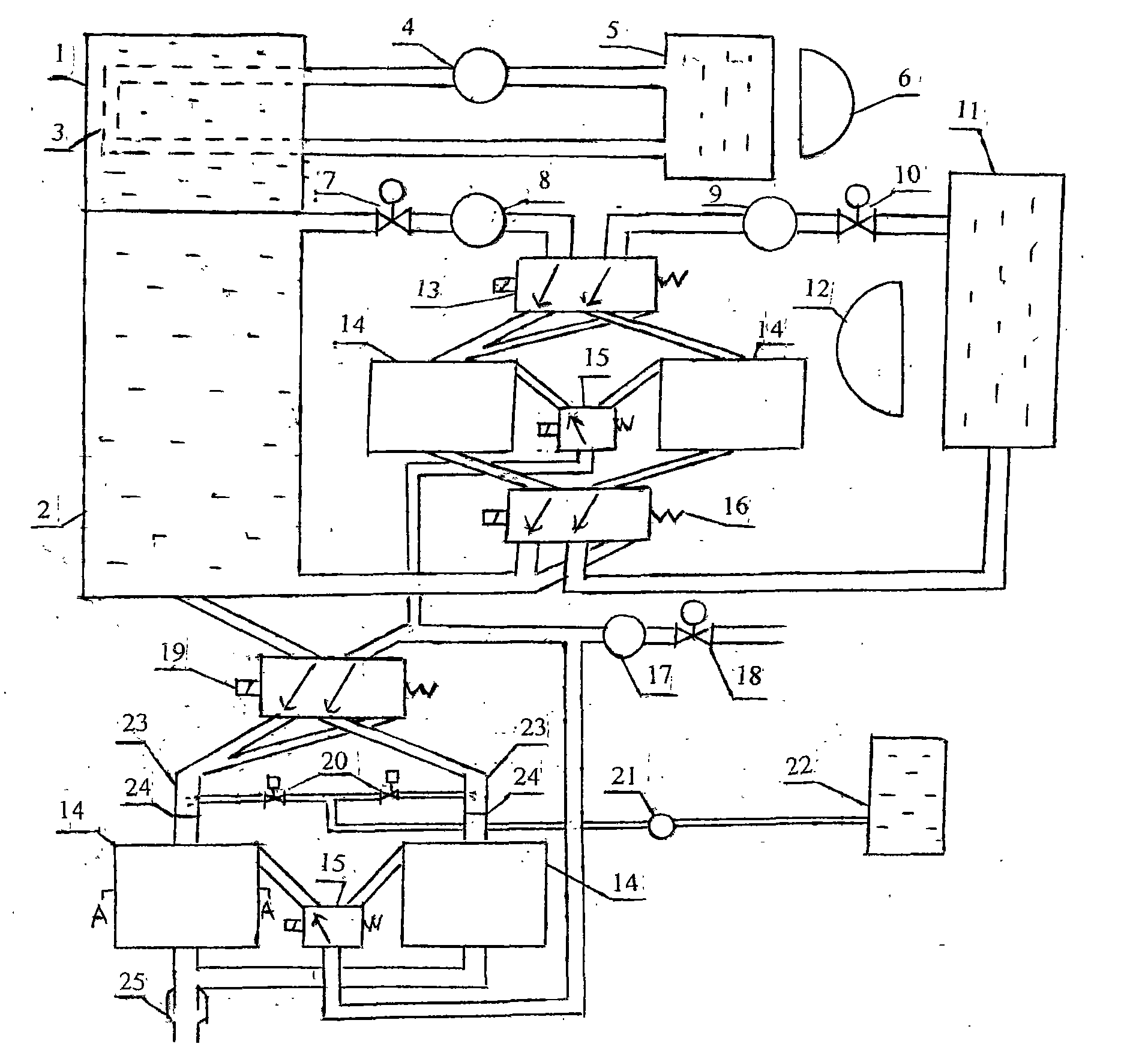

Method used

Image

Examples

Embodiment Construction

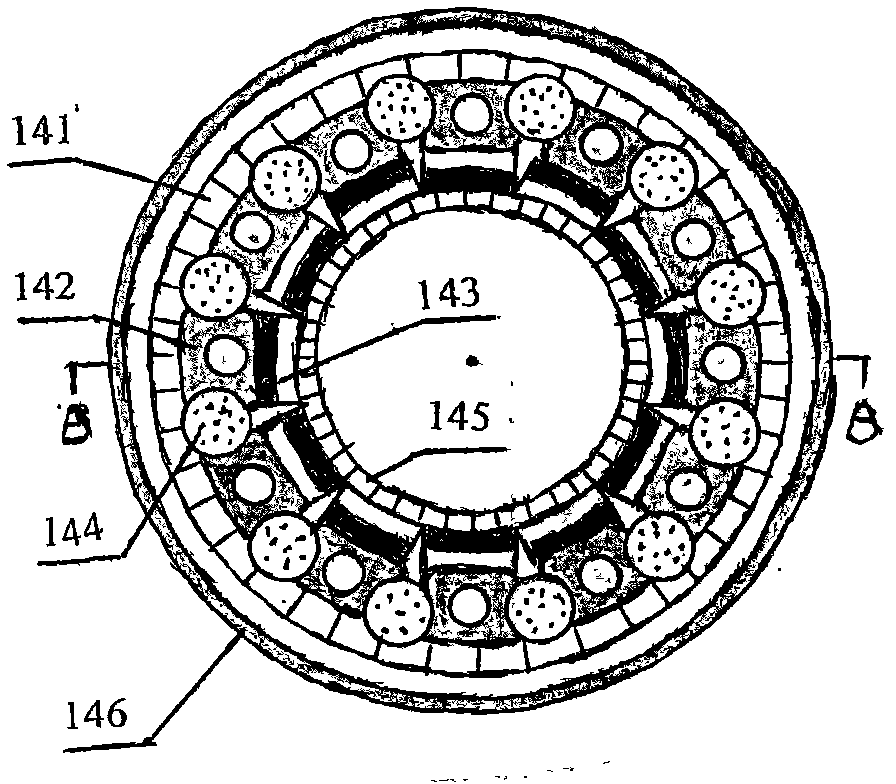

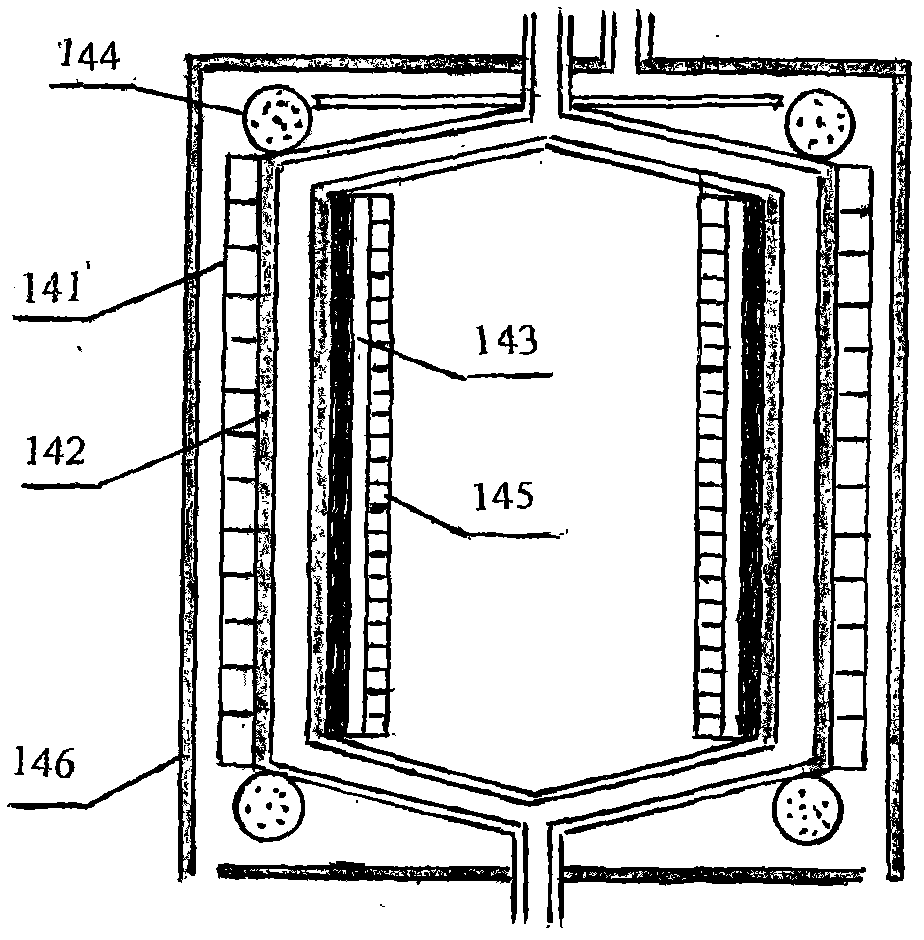

[0011] figure 2 , image 3 , shown, the automobile waste heat power generation device of the present invention, the inner side of the circular tubular soft iron pipe 141 of its generator 14 is pasted with many new alloys 142 centered symmetrically with the tube center line of the soft iron pipe 141 as the line of symmetry. A wire slot is formed between two adjacent new alloys 142, and the coil 144 is installed in the wire slot. There is a cold and heat exchange hole running through the whole new alloy 142 at the central position of each new alloy 142 section. A bar-shaped rare earth magnet 143 is pasted on the outer palm surface of each new alloy 142, and the magnetic polarity of the rare earth magnet 143 adjacent to the palm surface of the new alloy 142 is opposite. Another magnetic pole of the rare earth permanent magnet 143 is wrapped on a steel pipe 145 with the same core line as the soft iron pipe 141. There are insulation films between the new alloy 142 and the rare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com