Iron core structure of motor

A technology of iron core and structure, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, salient poles, etc., can solve the problems of insufficient mechanical strength of the iron core, and achieve the effect of high strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, an embodiment of a suitable motor core structure according to the present invention will be described with reference to the drawings.

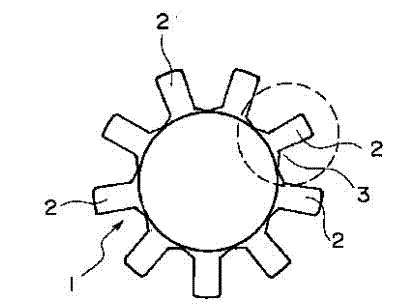

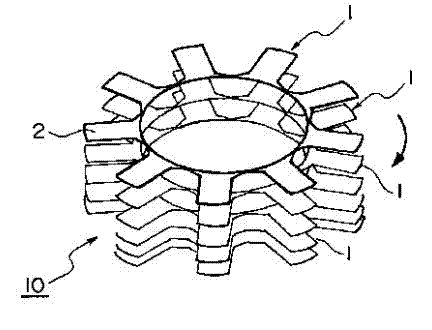

[0020] figure 1 It is a stamped wheel-shaped iron sheet 1, which is formed by a plurality of outwardly facing tooth portions 2. On the side of the tooth portion 2 of the above-mentioned core sheet 1, such as figure 2 The undercut 3 is shown formed. Such as image 3 As shown, a plurality of iron chips 1 are rotated and superimposed from the tooth portion 2 in the axial direction, that is, the commonly referred to as a rotation superimposed structure, thus forming a structure such as Figure 4 Iron cores 10 of a given thickness are stacked in turns as shown.

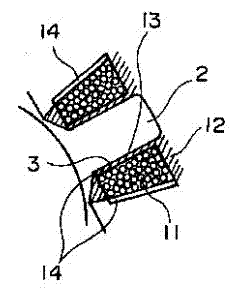

[0021] The above iron core 10 is in Figure 4 Coil 11 etc. are not set in, in fact it is as figure 2 As shown, the coil 11 of the insulating material 12 is coated on the periphery of the tooth portion 2 , so that a gap 13 is formed between the insulating materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com