Method for realizing the intelligent tour-inspection of power tower based on miniature multi-rotor unmanned helicopter

A multi-rotor unmanned, intelligent inspection technology, applied in the direction of controlling the starting method, aircraft parts, electrical components, etc., can solve the problems of not being able to effectively approach the observation target, the convenience of operation, and the large size of the aircraft. High efficiency, ensure safety, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is described in further detail:

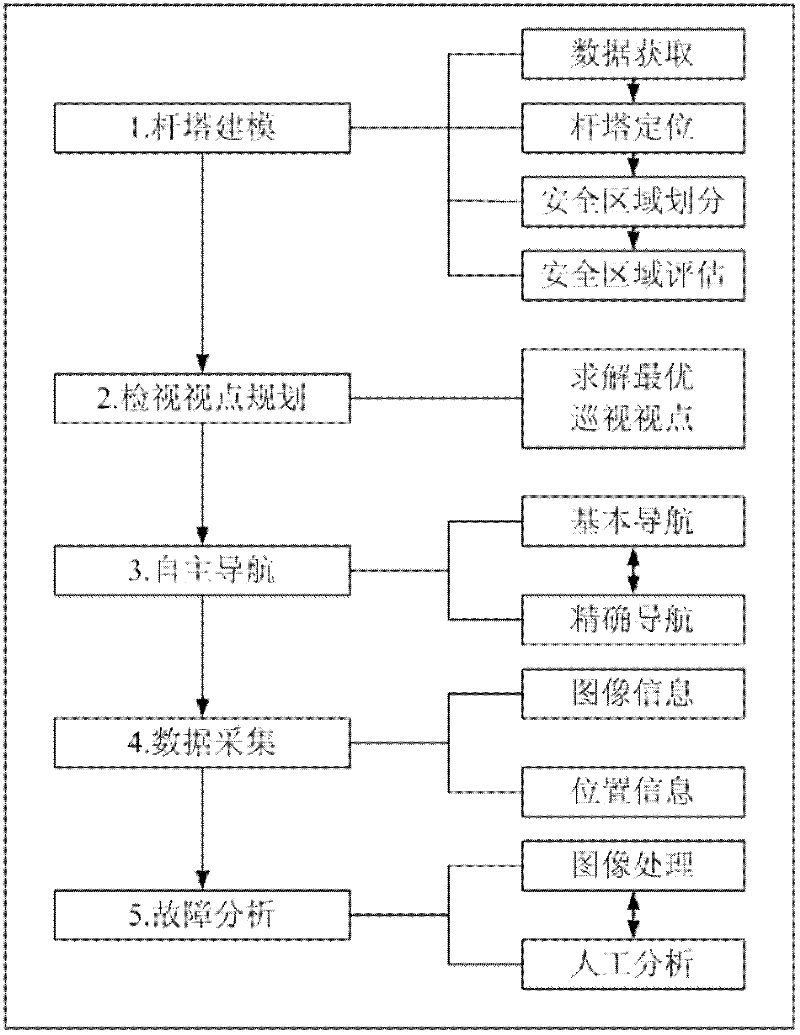

[0039] Such as figure 1 As shown, the intelligent inspection method of power poles and towers based on multi-rotor UAV. It is divided into the following steps: tower modeling, viewing viewpoint planning, autonomous navigation, data acquisition and failure analysis.

[0040] Tower modeling is divided into data acquisition process, tower positioning process, safety area division process and safety area evaluation process;

[0041]The data acquisition process is as follows: the basic structure of the tower is obtained through the engineering drawings provided by the designer of the transmission line, and on this basis, the more detailed structural characteristics of the tower are obtained by means of visual or laser testing, and the three-dimensional reconstruction process is completed;

[0042] The tower positioning process is as follows: according to the map and GPS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com