Industrial connector, and male head and female socket thereof

A connector and industrial technology, applied in the direction of connection, two-part connection device, and parts of the connection device, etc., can solve the problems of poor connection, structure shedding, instability, etc., and achieve the effect of tight and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

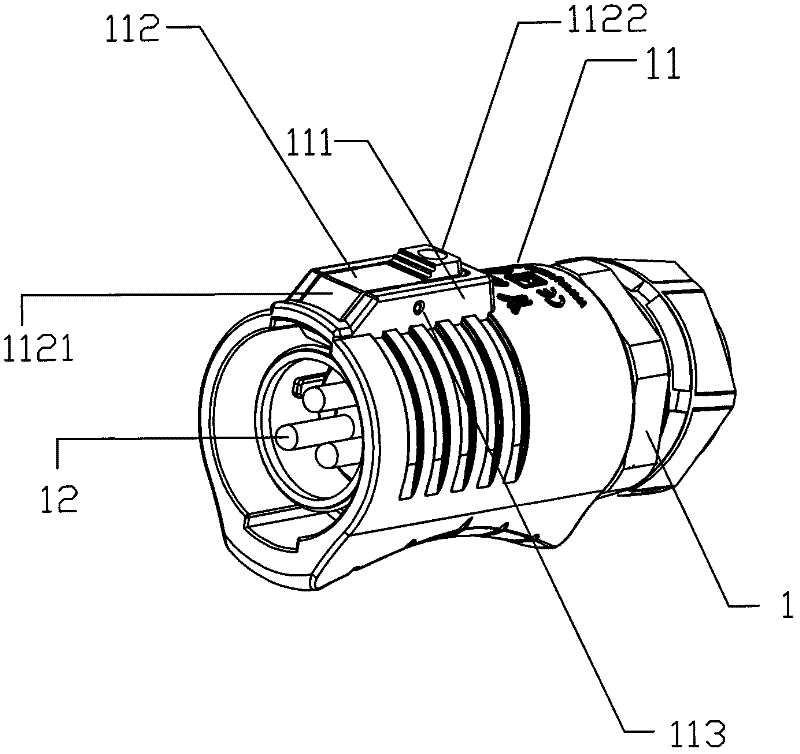

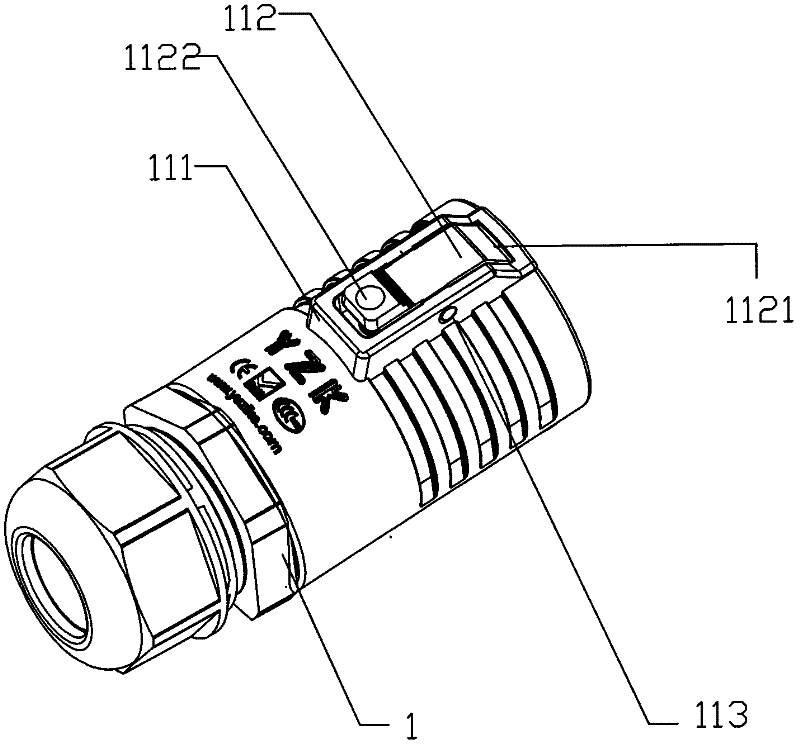

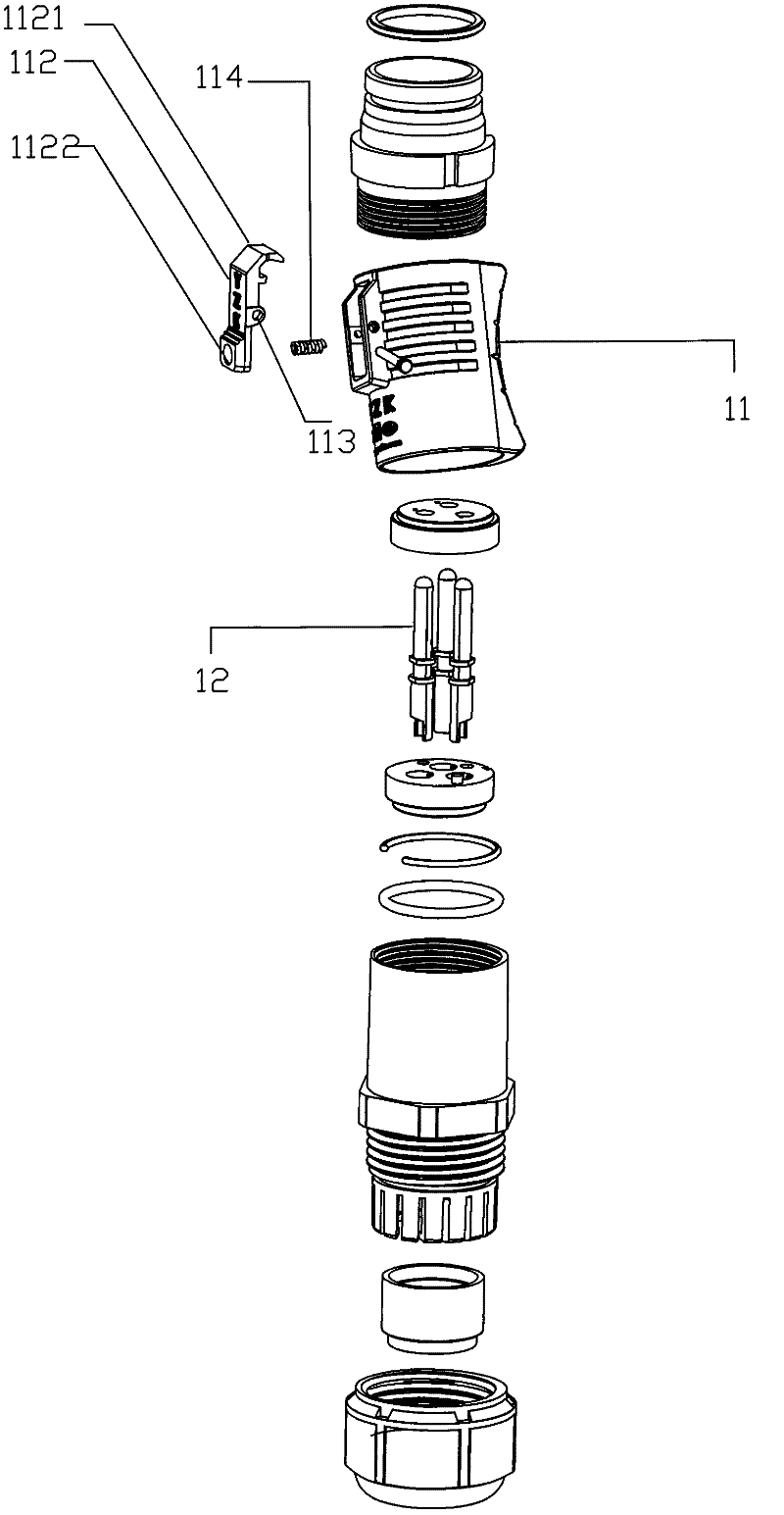

[0028] Refer below Figure 1-Figure 8 An embodiment of the 3-core industrial connector of the present invention is described in detail; as image 3 and Figure 8 As shown, this embodiment mainly includes a male head 1 and a female seat 2 connected by a plug-in type. The male head 1 includes a plug housing 11 and a ferrule assembly 12 arranged in the plug housing 11. The female seat 2 includes a socket cover 21 and a socket assembly 22 arranged in the socket cover 21, and a hook groove 111 is protruded on the outer surface of the plug cover 11 of the male head 1, and the hook groove 111 111 is provided with a hook 112, the hook 112 is screwed with the hook groove 111 through the pin shaft 113 arranged in the middle position, and one end of the hook 112 is provided with a hole that passes through the plug housing 11 toward Inside the hook head 1121, the other end is provided with a snap button 1122, and a spring 114 is arranged under the snap button 1122. One end of the spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com