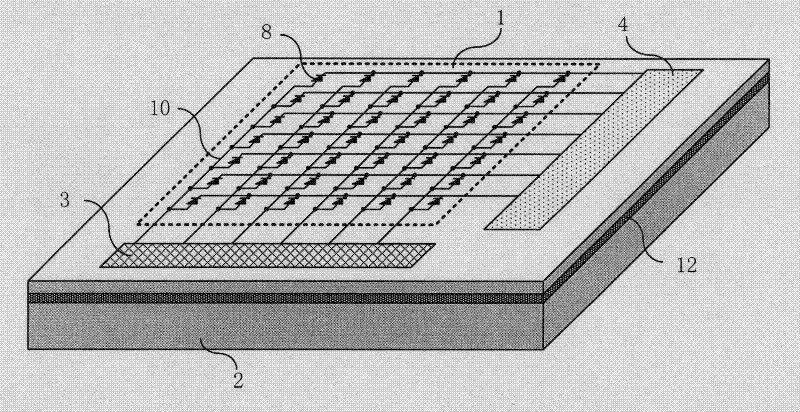

Design and preparation method of non-refrigeration infrared detector

An uncooled infrared and detector technology, applied in semiconductor devices, radiation control devices, final product manufacturing, etc., can solve the incompatibility of silicon micromachining technology, limit the miniaturization and integration of infrared detectors, detection sensitivity, and response speed Limited problems, to achieve the effect of convenient circuit design, low cost and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific example

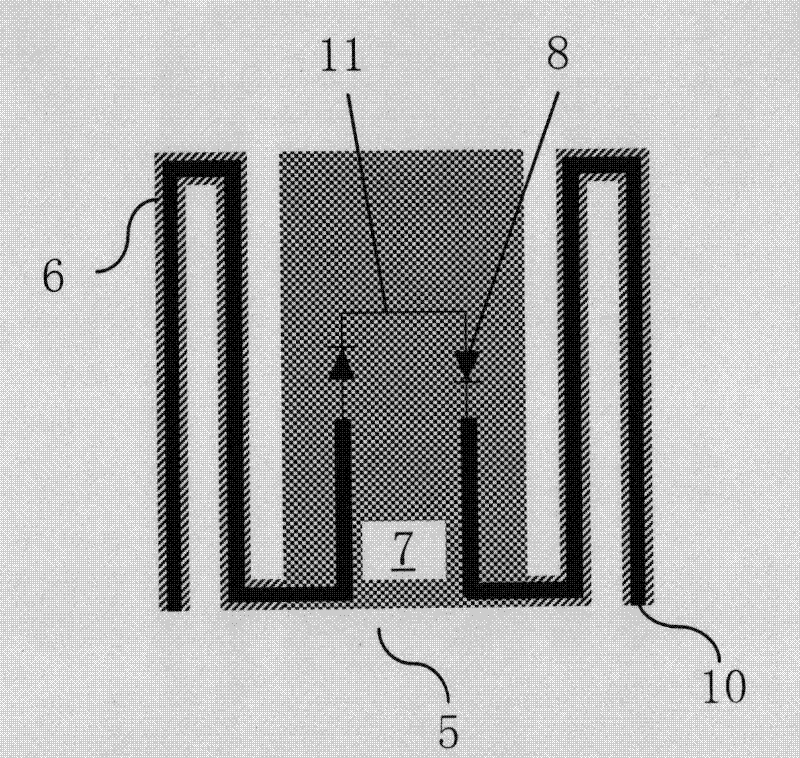

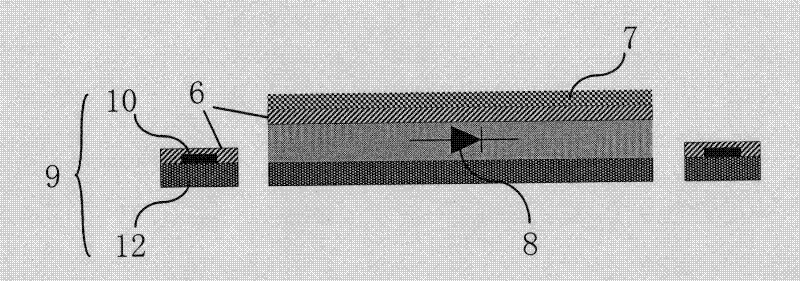

[0068] 1) The SOI substrate is used as the processing substrate, and the thickness of the device layer is Buried oxide layer thickness The thickness of the Si substrate is 525 μm. The first photolithography, the photoresist is used as a mask, and the device layer Si is etched to form a PN junction active region;

[0069] 2) The thickness of low pressure chemical vapor deposition is SiO 2 , perform boron ion implantation on the front side of the substrate, the implantation energy is 50KeV, and the implantation concentration is 1×10 13 / cm 3 , annealing at 1050°C for 4 hours, so that the implanted B ions diffuse uniformly in the device layer to form the P region of the PN junction;

[0070] 3) For the second photolithography, the photoresist is used as a mask, the N region of the PN junction is patterned, and phosphorus ions are implanted. The implantation energy is 80KeV, and the implantation concentration is 1×10 15 / cm 3 , wet etching removes step 2) the electrogene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com