Process method and lifting gripping apparatus both for jam control rod of nuclear power station reactor

A technology for nuclear power plant reactors and processing methods, applied in the field of million-kilowatt advanced pressurized water reactor nuclear power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1, a kind of stuck control rod processing method of nuclear power plant reactor, comprises the following steps:

[0074] (1) Place the control rod transport storage container: place the control rod transport storage container in the reactor pool and keep it upright. Specifically:

[0075] (11) Raise the new fuel elevator in the spent fuel pool to the water surface;

[0076] (12) Use a new fuel short handle tool to grab the control rod transport storage container, and use a crane to lift the control rod transport storage container into the new fuel elevator;

[0077] (13) Lower the new fuel elevator to the bottom of the spent fuel pool;

[0078](14) Use the spent fuel long rod tool to grab the control rod transport storage container at the new fuel elevator, and use the spent fuel bridge crane to put the control rod transport storage container into the side tilting machine basket of the fuel plant of the fuel transfer device;

[0079] (15) Use the fuel tran...

Embodiment 2

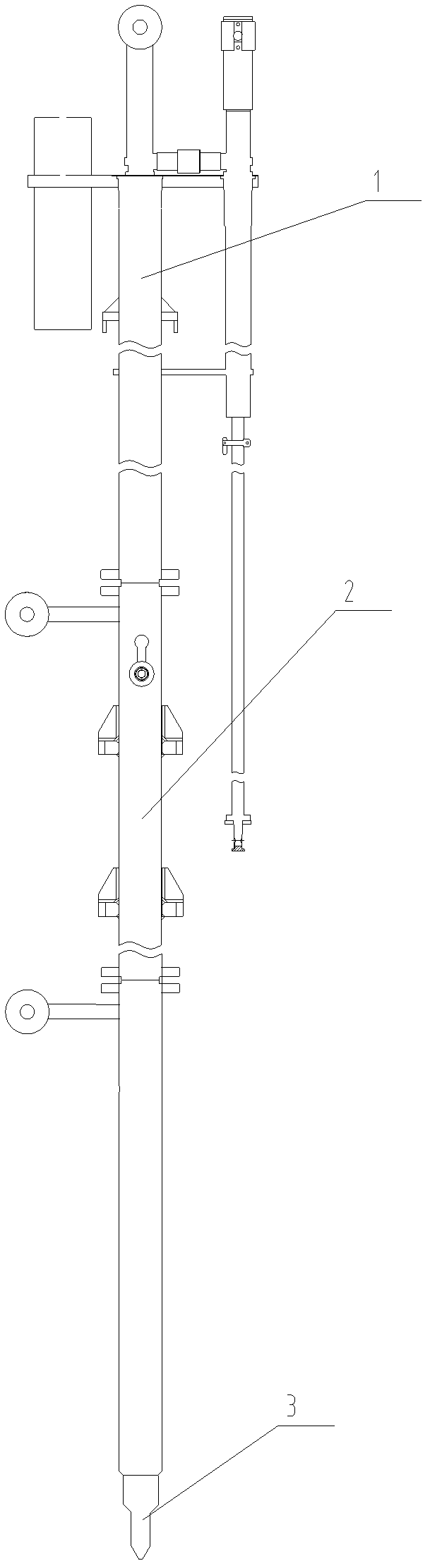

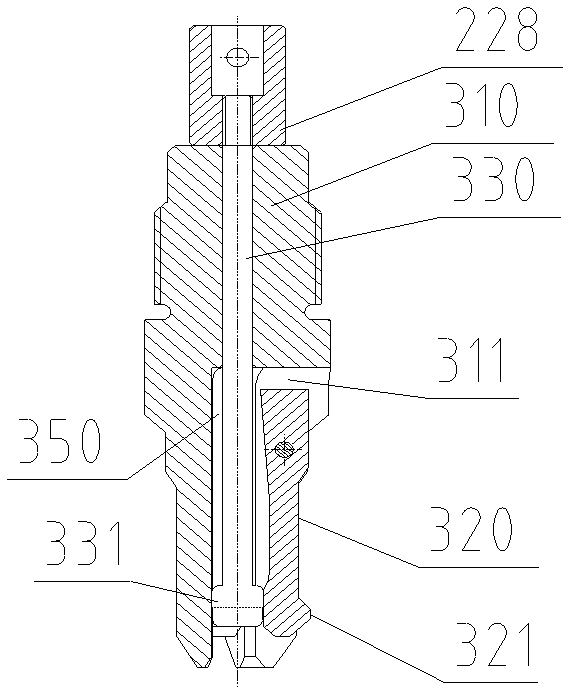

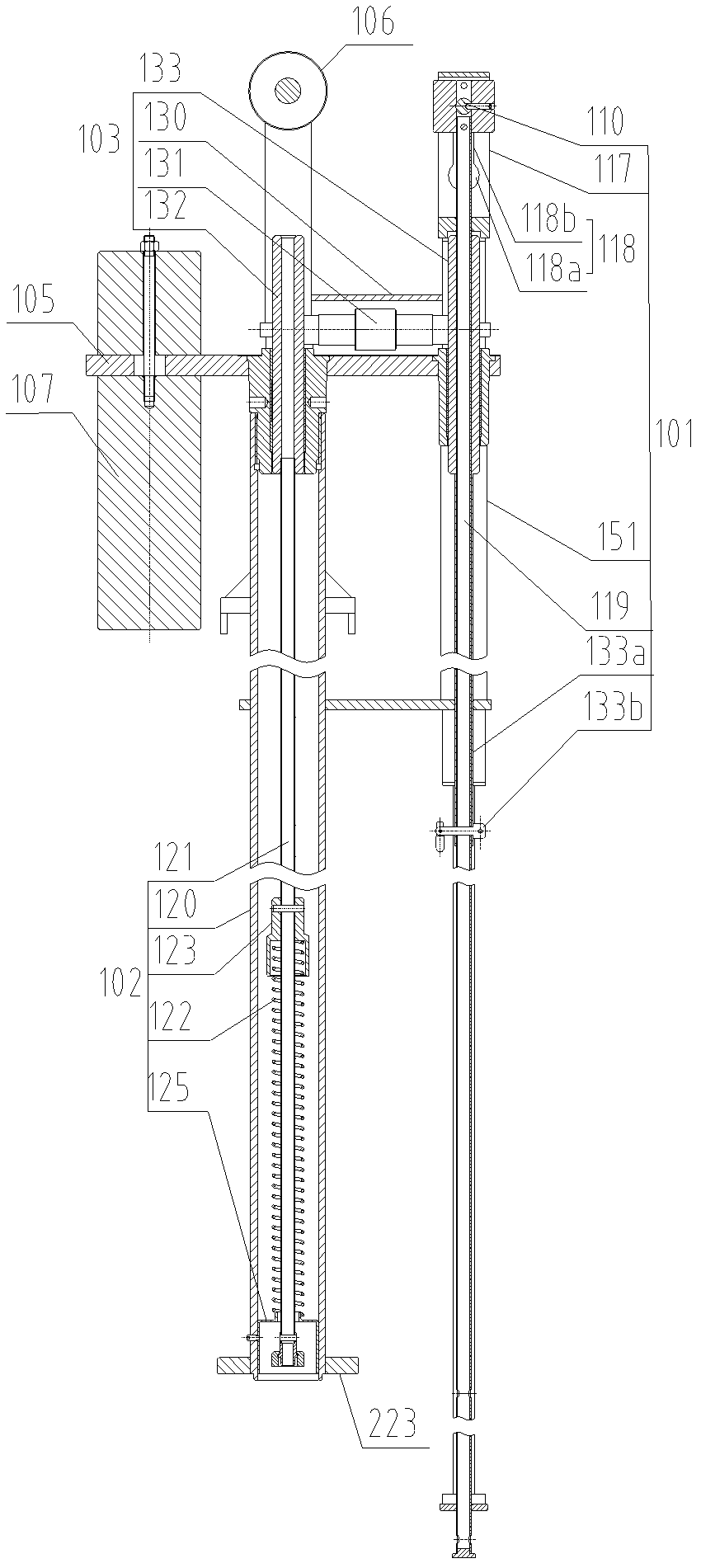

[0095] Embodiment 2, as Figure 1-6 As shown, a jamming control rod lifting gripper includes a grabbing mechanism 3 for grabbing the control rod that cooperates with the control rod, and the upper part of the grabbing mechanism 3 is sequentially connected with a manipulation mechanism 2 and a functioning mechanism 2 from bottom to top. The extension control mechanism 1 for adjusting the longitudinal position, the extension control mechanism 1 and the control mechanism 2 are fixedly connected or the two are detachably fixedly connected, and the operation of the extension control mechanism 1 and the control mechanism 2 can respectively drive the grasping mechanism 3 to act Grasp the control stick or let go of the control stick. Since the gripper is used for grasping the control rod at a depth of about 12 meters, the gripper as a whole is a slender rod-shaped structure, and the control mechanism 2 is a slender structure, and the extension of the control mechanism 1 is also to len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com