Method for quickly and nondestructively measuring thickness and band structure of graphene film

A technology of graphene film and energy band structure, which is applied in the direction of measuring devices, instruments, and polarization-influenced characteristics, to achieve the effects of increasing detection speed, reducing difficulty, and simplifying complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

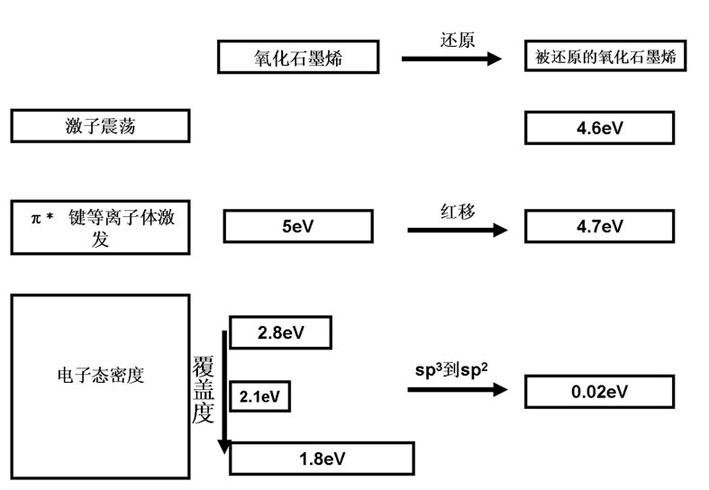

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The method for measuring the energy gap gradient of graphene thin films proposed by the present invention can be applied to the measurement of electronic energy gaps of graphene thin films such as FRGO and GO. What is described below takes the detection of energy gap changes before and after the reduction of GO thin films as an example. process flow.

[0018] First, grow a layer of SiO on the silicon substrate 101 2 Thin film 102, then transfer GO or FRGO to SiO 2 On, generate thin film 103, such as figure 1 shown.

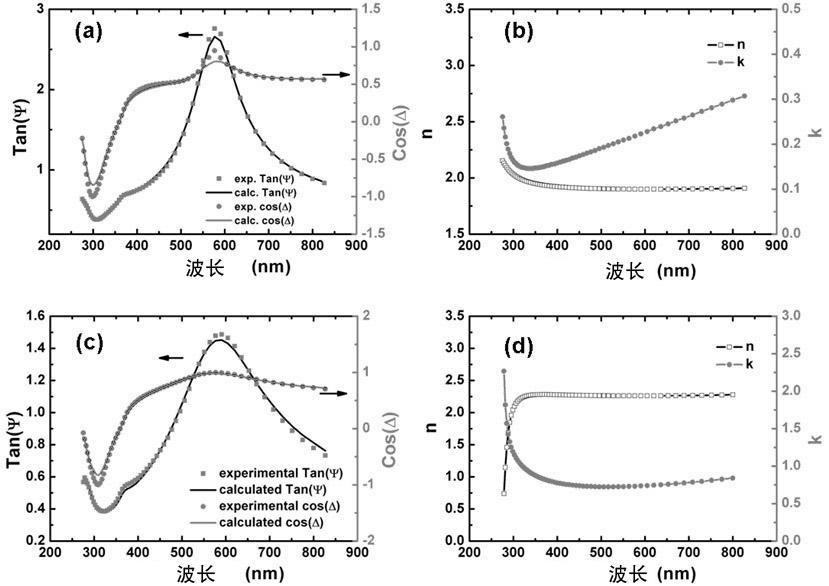

[0019] Next, the ellipsometric data of GO and FRGO thin films were obtained by ellipsometry, and the spectra of GO and FRGO thin films are as follows figure 2 (a) and (c) are shown by the solid line.

[0020] Next, establish a theoretical model, here we use the classic Lorentz oscillator model for analysis. The compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com