Measuring device and measuring method of superconductive AC magnetic susceptibility

An AC magnetic susceptibility and measuring device technology, applied in the field of superconducting electronics, can solve the problems of high price, increase temperature measurement error, etc., and achieve the effect of slowing down the temperature change speed, reducing the temperature hysteresis effect, and reliable testing means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

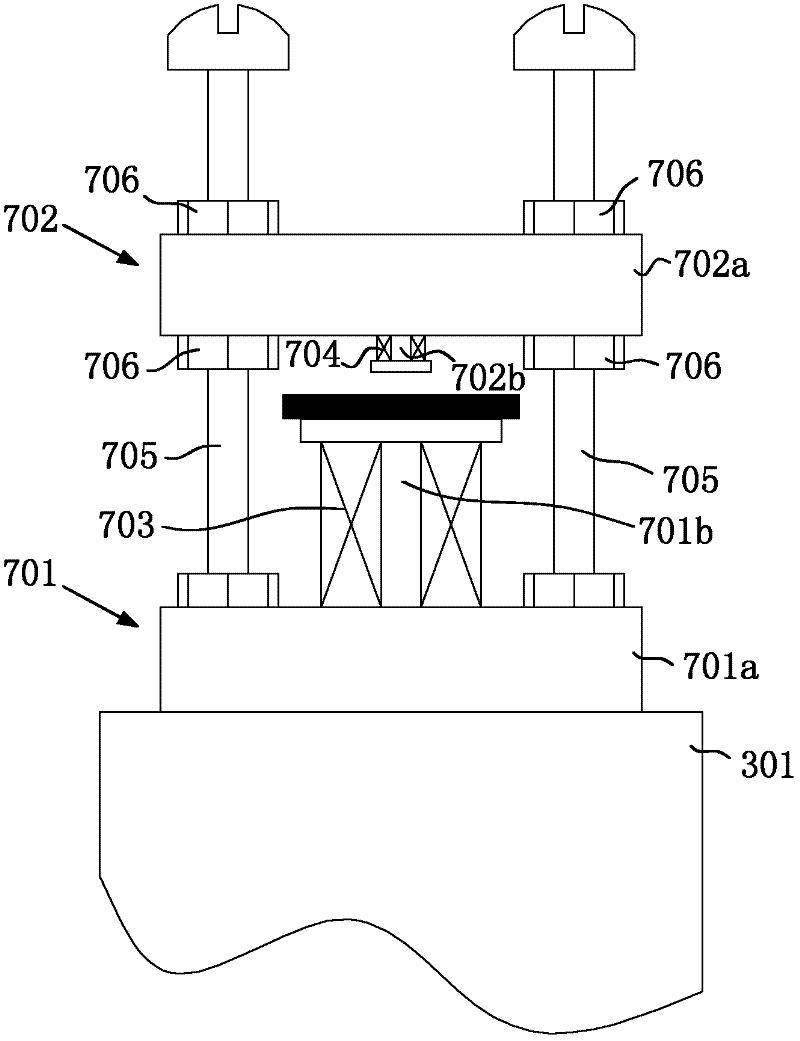

[0037] The invention is a superconducting AC magnetic susceptibility measuring device, such as figure 1 As shown, it includes a vacuum chamber 1, a vacuum pump 2, a compression refrigerator 3, a lock-in amplifier 4, a temperature controller 5, a computer 6 and a coil group 7;

[0038] Wherein, the vacuum chamber 1 is a closed structure, the vacuum pump 2 communicates with the vacuum chamber 1 through a pipeline, and a vacuum valve 201 is installed on the pipeline. The compression refrigerator 3 has a columnar heat-conducting copper 301. The columnar heat-conducting copper 301 is used as the cooling end of the compression refrigerator, extending from the bottom of the vacuum chamber 1 into the vacuum chamber 1. heat, the compression refrigerator 3 can reduce the temperature in the vacuum chamber 1 to below 50K, which can meet the transition temperature requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com