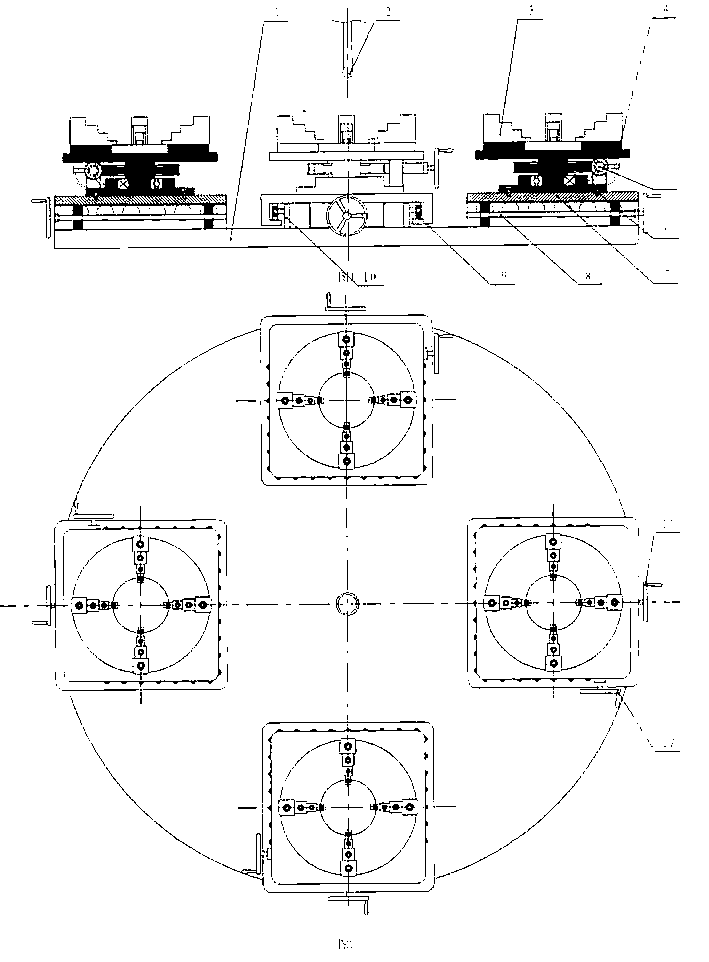

Radiography inspection stand of nuclear power cast steel members

A technology of radiography and steel castings, which is applied in the direction of using radiation for material analysis, etc., to achieve the effect of reducing inspection costs, clamping castings firmly, and being safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention demonstrates the implementation mode through its working principle. When in use, the gate of the closed inspection room is opened, castings are placed on each station of the indoor inspection table, and the four-jaw chuck 3 is used for clamping. Turn the carriage 7, the lower screw, the 8-axis, the upper hand wheel 11, adjust the distance from the center of the casting to the center of the disc on each station to meet the requirements of the focal length of the film, and arrange the film at the inspection position of each casting. Shake the handwheel 12 on the 5th axis of each worm, drive the worm gear 6 to drive the turntable 4 to rotate, select a satisfactory angle, and then take pictures of the cloth for inspection. After the inspection of one end is over, after the casting is fixed, the other end is photographed in turn until the entire volume of the casting is inspected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com