Electromagnetic excitation detection-based resonant tuning fork liquid density sensor

A liquid density and electromagnetic excitation technology, applied in the field of high-precision online measurement of liquid density, high-precision resonant quasi-digital sensors, and resonant tuning fork liquid density sensors, can solve the problem that the vibrating membrane method is not easy to stabilize, the vibrating string method has a complex structure, and Vibration frequency is not stable enough to achieve the effect of improving anti-interference ability, low power consumption and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

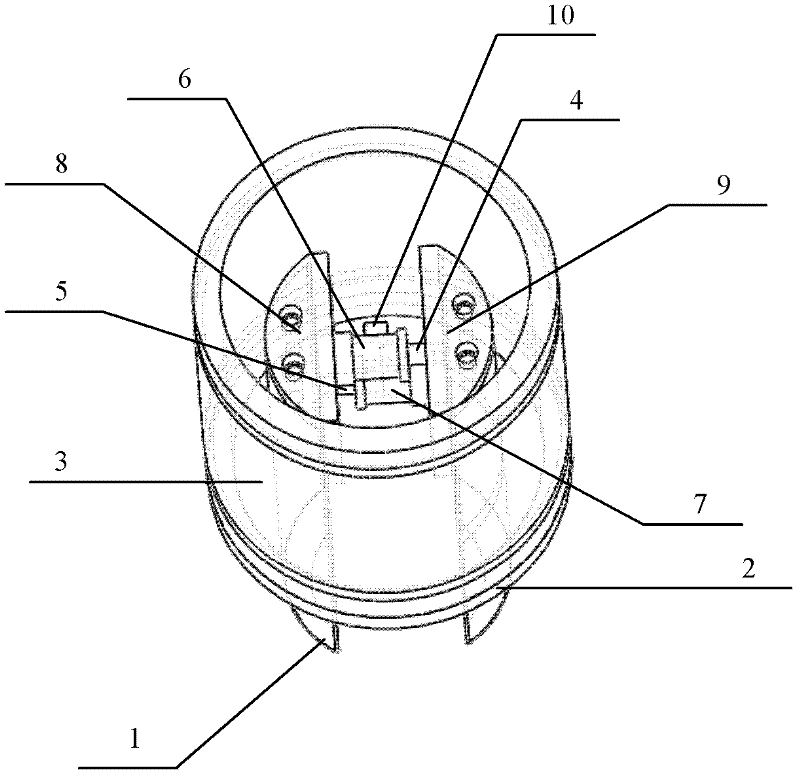

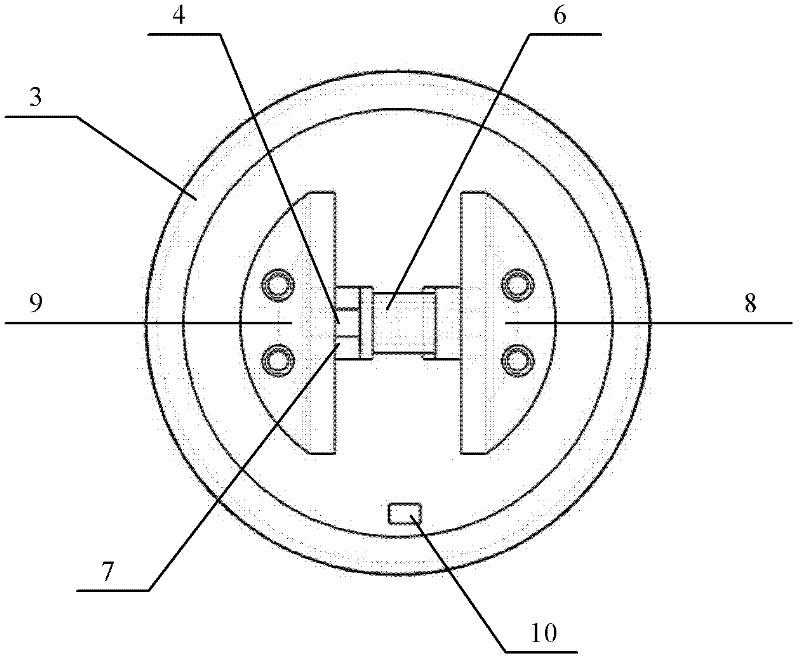

[0024] Such as figure 1 As shown, the resonant tuning fork liquid density sensor of electromagnetic excitation detection of the present invention is made of tuning fork body 1, solid support body 2, protection tube 3, first magnetic cylinder 4, second magnetic cylinder 5, first coil 6, second The coil 7, the first fixing part 8, the second fixing part 9 and the temperature sensor 10 are composed.

[0025] Such as figure 2 , image 3 , Figure 4 , Figure 7 As shown, the protective tube 3 is welded on the solid support body 2, and an undercut groove with a radius of 1 mm to 2 mm is processed at a distance of 3 mm to 5 mm (4 mm in this embodiment) from the two end faces of the protective tube 3 (in this embodiment 1mm), to eliminate the influence of stress on the vibration frequency of the tuning fork body 1. The depth that the first magnetic cylinder 4 enters the first coil 6 is times the length of the coil, respectively through the first fixture 8 and the second fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com