Comprehensive quickly-disassembled clamping hoop test system

A comprehensive test and clamp technology, applied in the field of quick-release clamp comprehensive test system, can solve the problems of inaccurate test results, low work efficiency, high labor intensity, etc., to facilitate collection and calculation, save labor, and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

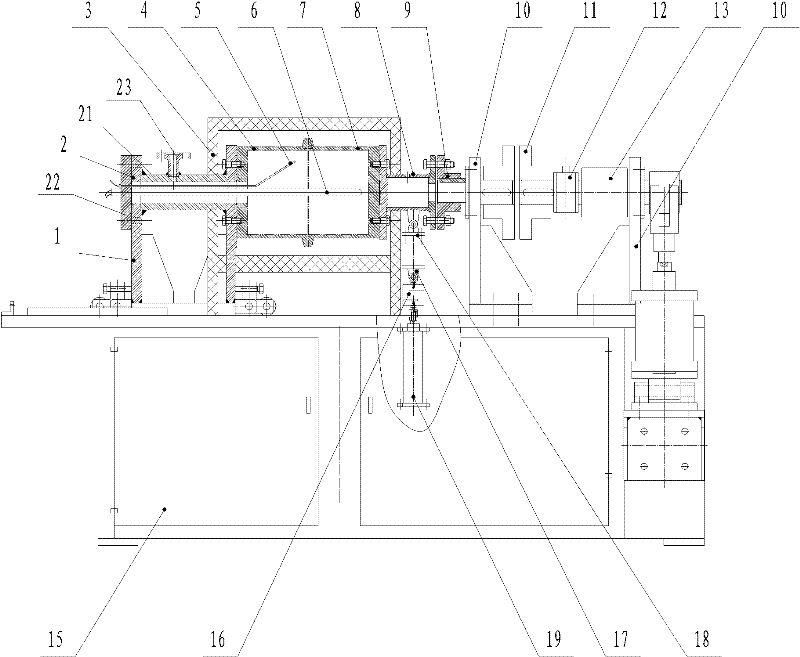

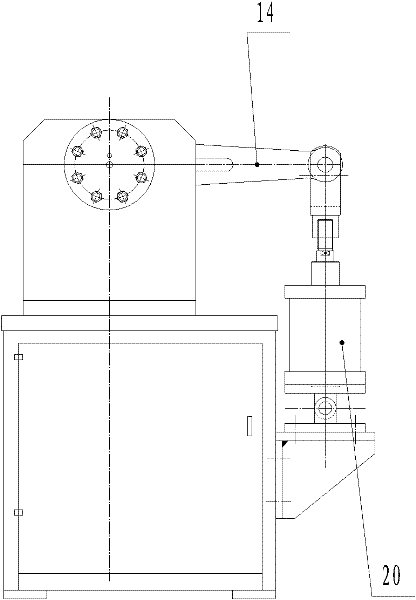

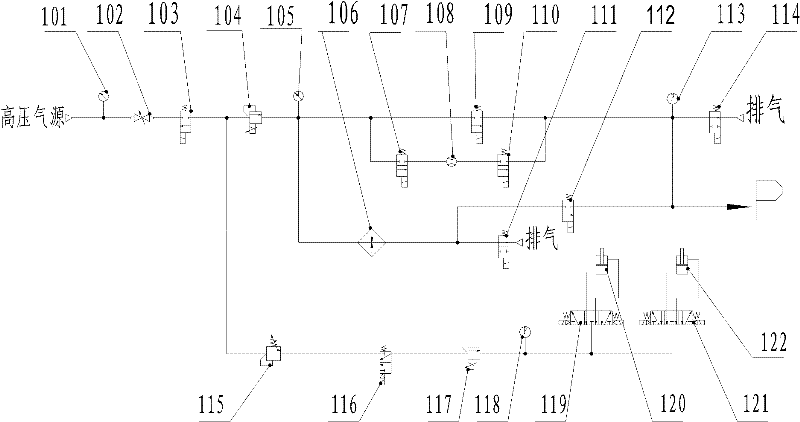

[0023] The present invention includes a mechanical structure and a pneumatic circuit, wherein the mechanical structure refers to figure 1 with figure 2 As shown, including platform body 15, front support 1 and rear support 10 are installed on the top of platform body 15, and front support 1 is provided with heating rod 6 and temperature sensor 5, and one side of front support 1 is fixedly connected with left Conduit 4, the left conduit 4 is connected to the right conduit 7 through a clamp, the right conduit 7 is connected to the movable flange 9 through the middle flange 8, and the lower part of the middle flange 8 is connected to the bending moment upper flange 18, the bending moment upper flange 18 The lower part of the flange 17 is provided with a bending moment lower flange 17, and the bending moment lower flange 17 is connected with a bending mome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com