Weighing error automatic compensation method of vehicle scale

An error compensation and automatic compensation technology, applied in neural learning methods, detailed information of weighing equipment, weighing, etc., can solve problems such as poor compensation effect and large difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

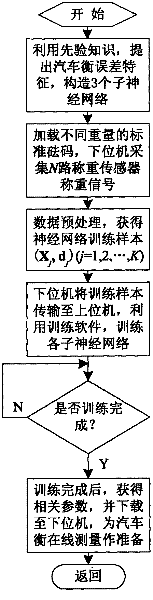

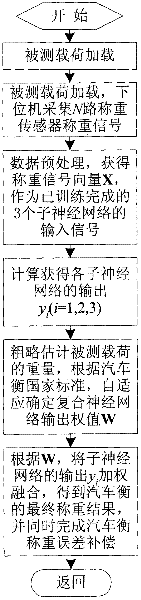

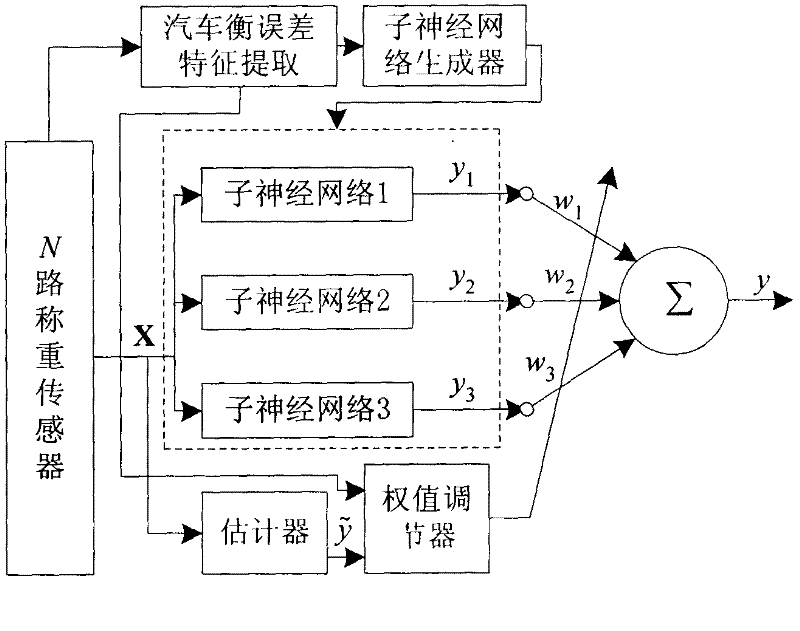

Method used

Image

Examples

Embodiment 1

[0043] It is assumed that in this embodiment, the truck scale has 8 load cells (N=8), the measuring range is 40 tons, the maximum capacity of each load cell is 20 tons, the number of divisions is 4000, and the verification division value e and the actual The division value d is 10kg. The high-performance single-chip microcomputer MSP430F449 of TI Company is used as the lower computer 10 .

[0044] (1) Compound neural network structure. In this embodiment, the sub-neural network adopts a radial basis function neural network (RBFNN), and the basis function of the RBFNN adopts a Gaussian function. According to the method shown in formula (1), three sub-neural networks are constructed. Taking sub-neural network 1 as an example, the sub-neural network at this time is a network with 8 inputs and 1 output, so its output is

[0045] y 1 = b 1 + Σ j ...

Embodiment 2

[0057] Set in this embodiment, the truck scale has 6 load cells (N=6), the measuring range is 40 tons, the maximum capacity of each load cell is 20 tons, the division number is 4000, the verification division value e and the actual The division value d is 10kg. The DSP TMS320VC5502 of TI Company is adopted as the lower computer 10 .

[0058] (1) Compound neural network structure. In the present embodiment, sub-neural network adopts BP neural network (BPNN), and the hidden layer activation function f of BPNN 1 Using the S-shaped function, the output layer activation function f 2 Using a linear function, taking sub-neural network 1 as an example, the sub-neural network at this time is a network with 6 inputs and 1 output, so its output is

[0059] y 1 = W 2 F 1 + b 2 = W ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com