Laser ultrasonic thickness measuring method and laser ultrasonic thickness measuring device capable of being used for field detection

A laser ultrasonic and on-site detection technology, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of increased device testing flexibility, inappropriate on-site testing, and high laser cost, achieving simple structure, low cost, Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

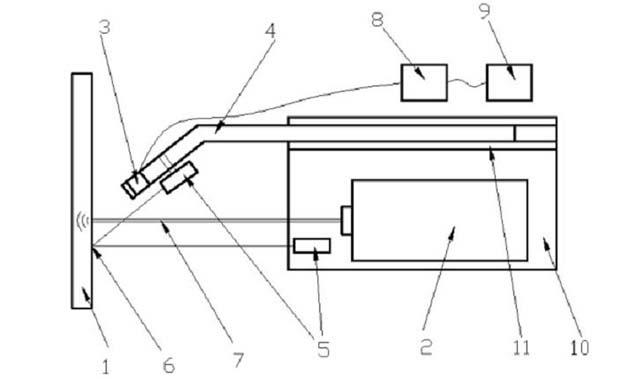

[0015] Such as figure 1 The laser ultrasonic thickness measuring device shown is mainly composed of a laser 2 , a main support 10 , an air-coupled sensor 3 , a support rod 4 , a centering device 5 , a signal processing system 8 and a display system 9 . The laser 2 and the transmission rod 4 are installed on the main support, and a guide rail 11 parallel to the laser beam is arranged on the main support. The rear end of the support rod 4 is installed on the guide rail 11 and can slide back and forth on the guide rail. An air-coupled sensor 3 is arranged at the front end of the rod 4 . The centering device is composed of two small lasers, one is arranged on the pole 4, and its light direction is parallel to the direction in which the air-coupled sensor 3 receives the signal, and the other is arranged on the main support 10, and its light direction is in line with the direction in which the laser emits laser light. direction parallel. The signal processing system 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com