Bearizing drilling bit

A technology of reaming drill bit and drill bit, which is applied to drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems such as the deviation of the drilling hole center, the difficulty of retracting the fins, and the inability to retract the reaming fins, so as to improve the reliability. , the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

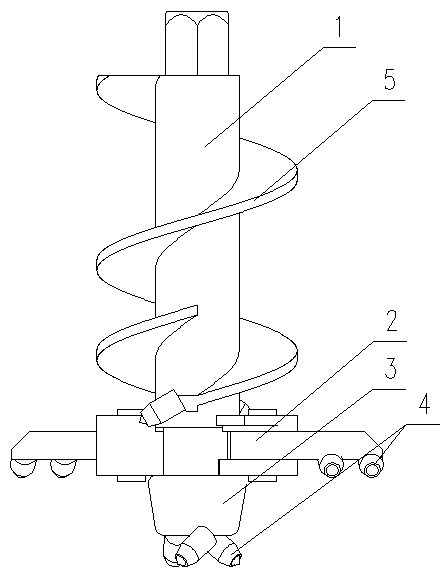

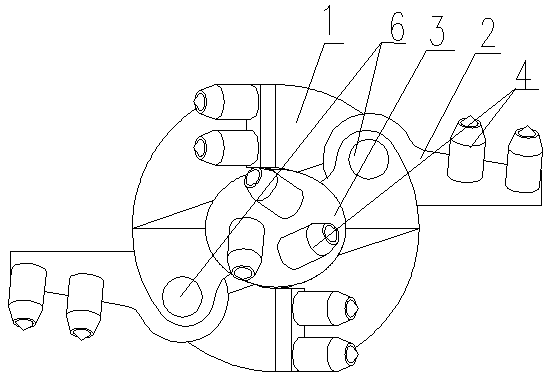

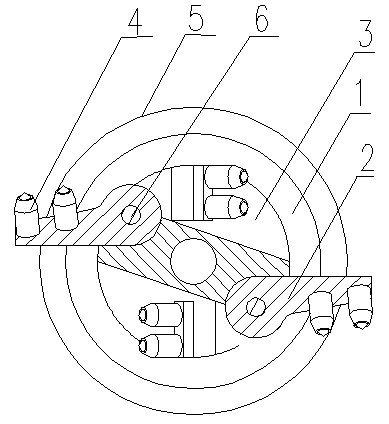

[0023] Such as Figure 1 to Figure 4 For the reaming drill shown, double helical blades 5 are arranged on the side wall of the drill main body 1, and two reaming wings 2 are symmetrically arranged on the drill main body 1 above the drill guide head 3, and the drill main body 1 is symmetrically arranged with The reaming wing 2 has the same number of grooves, one end of the reaming wing 2 is hinged in the groove through the pin shaft 6, and the reaming wing 2 can rotate around the pin shaft 6 to realize retraction and opening, and the reaming wing 2. The connecting end with the drill bit main body 1 is a cylindrical contact surface; the contact surface with the reaming wing 2 in the groove is a cylindrical concave contact surface, and the two have a common center of circle, that is, the axis of the connecting pin 6 of the two. Heart, the two do not form a cavity after cooperation. Drilling teeth 4 are arranged on the drill bit main body 1 , its guiding head 3 , and the reaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com