Compressing frame device for level delivering and stamping of fabric

A frame-pressing and flattening technology, applied in the elongation of fabrics, fabric surface trimming, textiles and papermaking, etc., can solve the problems of flatness, displacement, and defective products, and achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

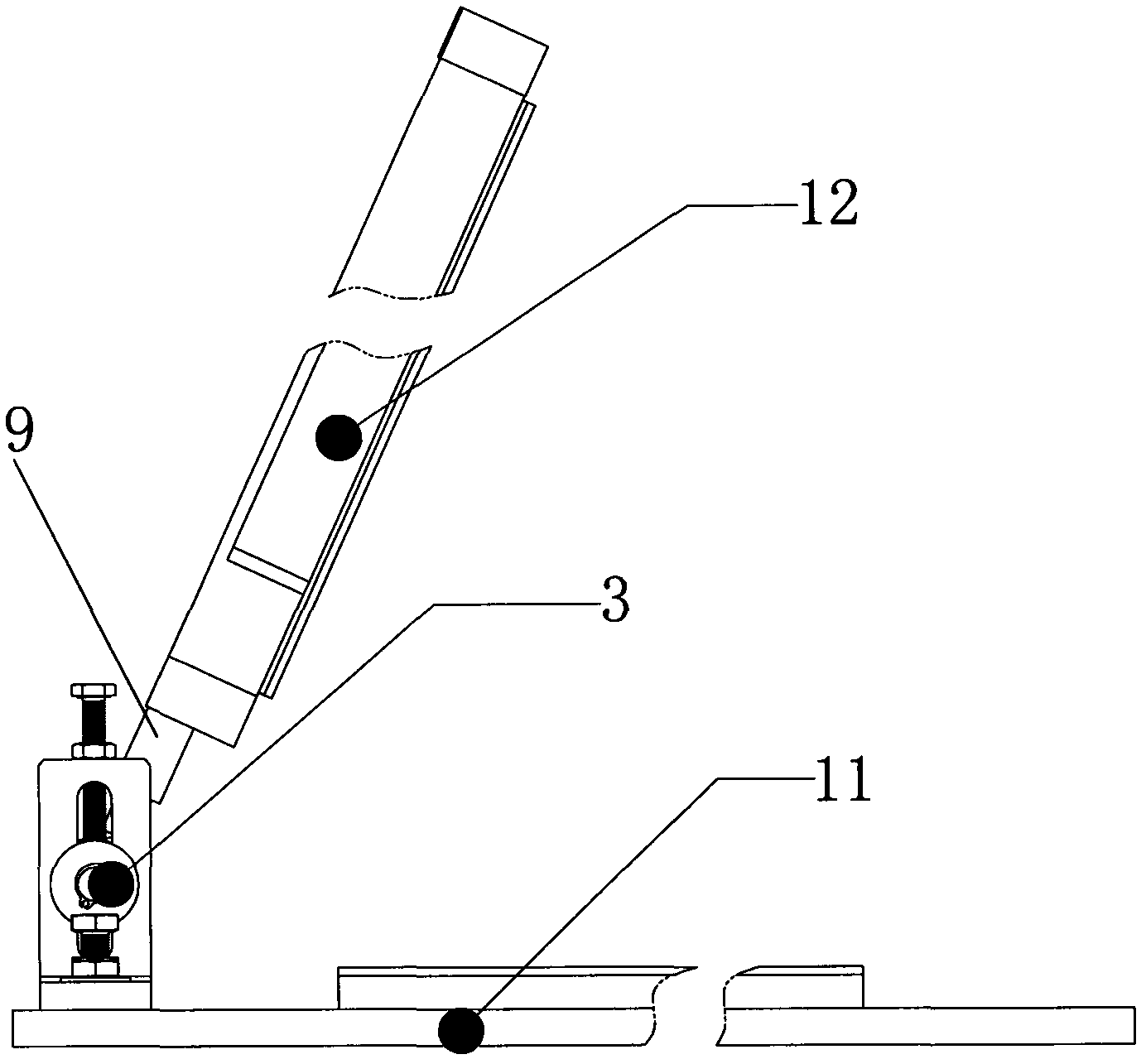

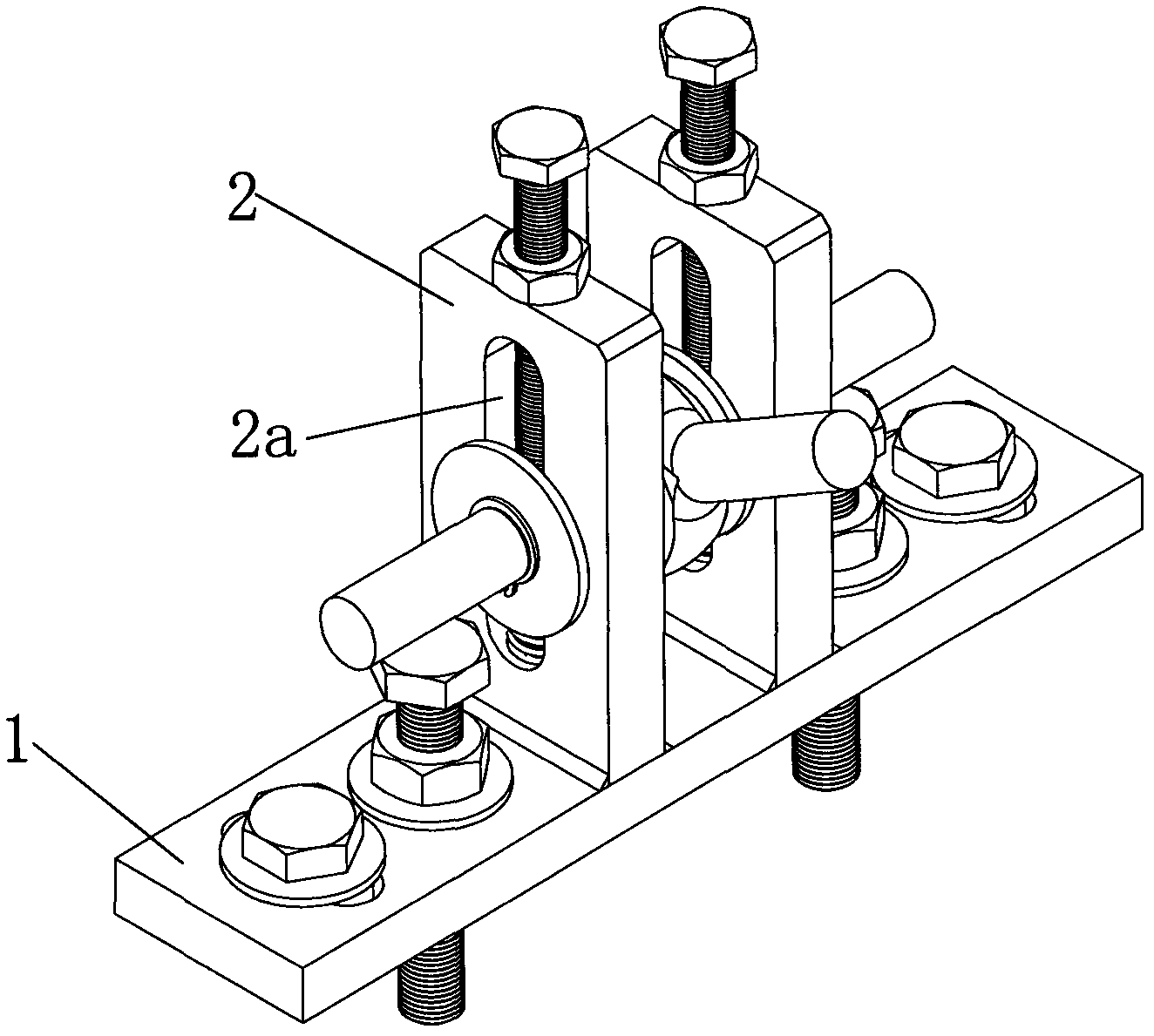

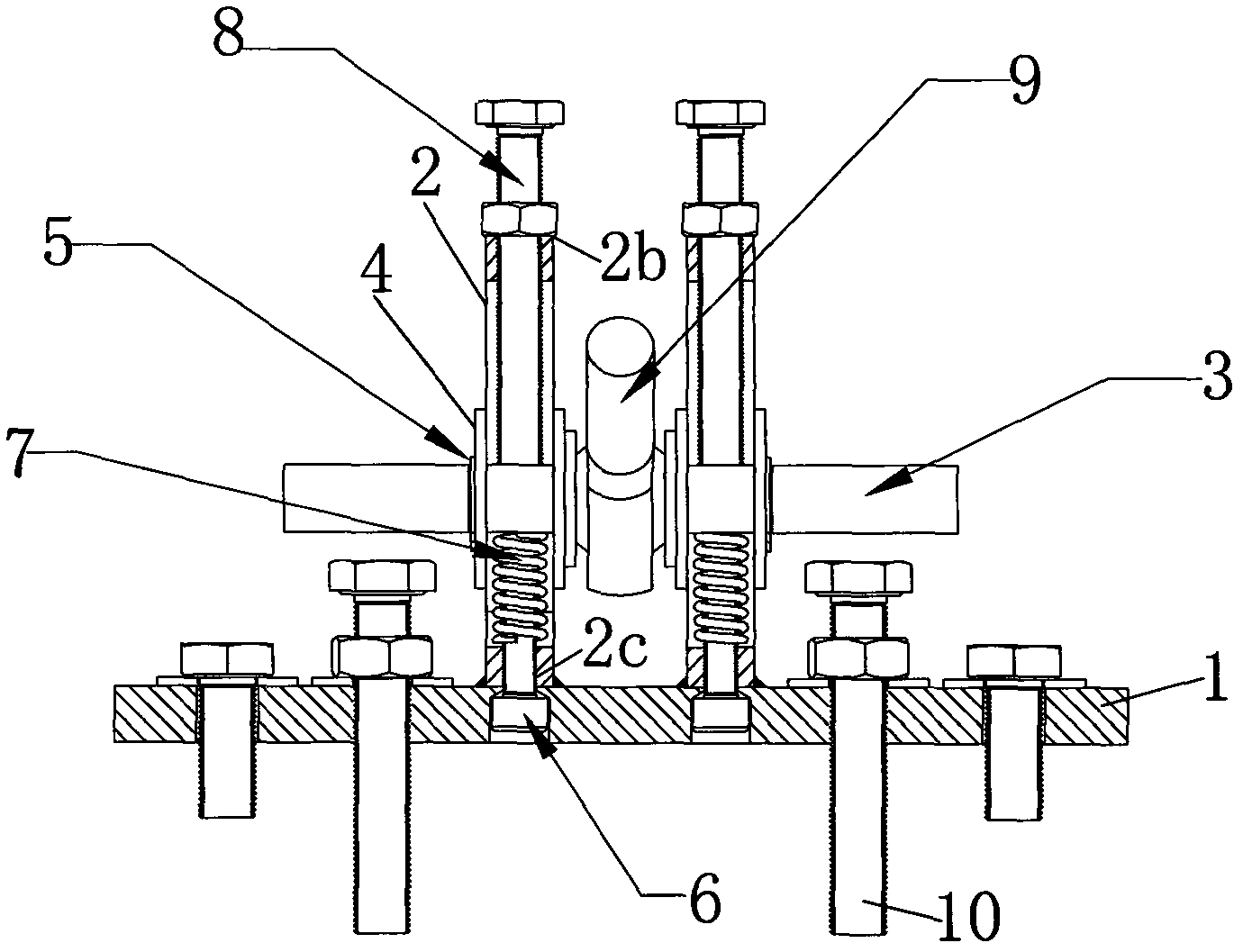

[0017] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0018] refer to figure 2 and image 3 , the connection mechanism has a horizontal plate 1; a pair of parallel vertical plates 2 are distributed on the horizontal plate 1, and the side of the vertical plate 2 is provided with a strip hole 2a; the strip hole 2a on the vertical plate 2 is provided with an adjustment hole 2b, Its bottom surface has fixed screw hole 2c; A floating shaft 3 passes through two strip holes 2a and is located in the two strip holes 2a; The floating shaft 3 is equipped with retaining rings 4 and The snap ring 5 is used to limit the movement of the floating shaft 3 in the left and right direction; the fixing screw 6 is installed in the fixing screw hole 2c, and the end of the fixing screw 6 is covered with a compression spring 7, and the other end of the compression spring 7 acts on the floating shaft 3; The adjustment screw 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com