Fireproof silicone foam material and preparation method thereof

A silicone foam and formula technology, applied in the field of polymer fireproof materials, can solve the problems of inconvenient maintenance and replacement, inability to compensate for the mechanical displacement of mechanical pipes, etc., and achieve the effects of easy construction and replacement, small specific gravity, and good flame retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

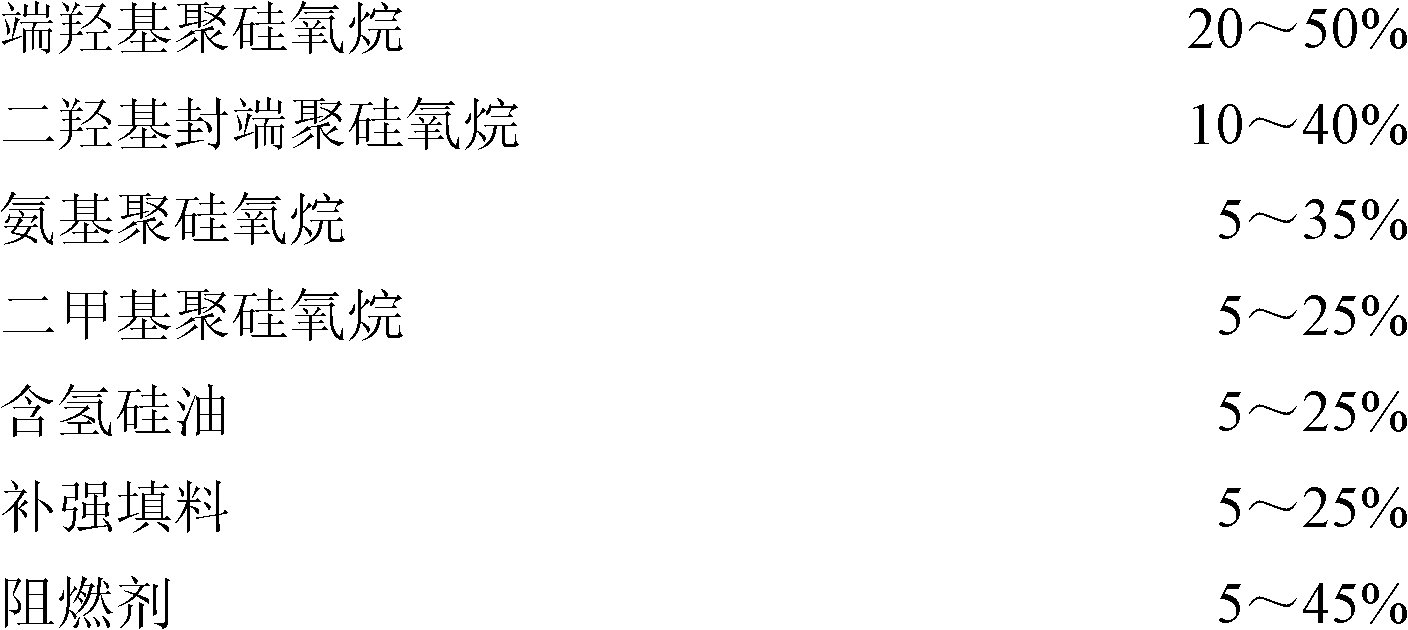

[0038] a) Take by weighing each raw material according to the following formula:

[0039] The composition formula of A component is as follows:

[0040]

[0041] The composition formula of B component is as follows:

[0042]

[0043] b) Put the hydroxyl-terminated polysiloxane, dihydroxy-terminated polysiloxane, aminopolysiloxane, and dimethyl polysiloxane in component A through a vacuum kneader at 50-150°C, and the vacuum degree is - Vacuum kneading at 0.1-0.05MPa for 30-120 minutes, then add hydrogen-containing silicone oil, stir and mix at high speed for 30-60 minutes, then add flame retardant, reinforcing filler, stir and mix to obtain component A;

[0044] c) Put the hydroxyl-terminated polysiloxane, dihydroxy-terminated polysiloxane, aminopolysiloxane, and dimethyl polysiloxane in component B through a vacuum kneader at 50-150°C, and the vacuum degree is - Vacuum kneading at 0.1-0.05MPa for 30-120 minutes, then add platinum group catalyst, stir and disperse at hi...

Embodiment 2

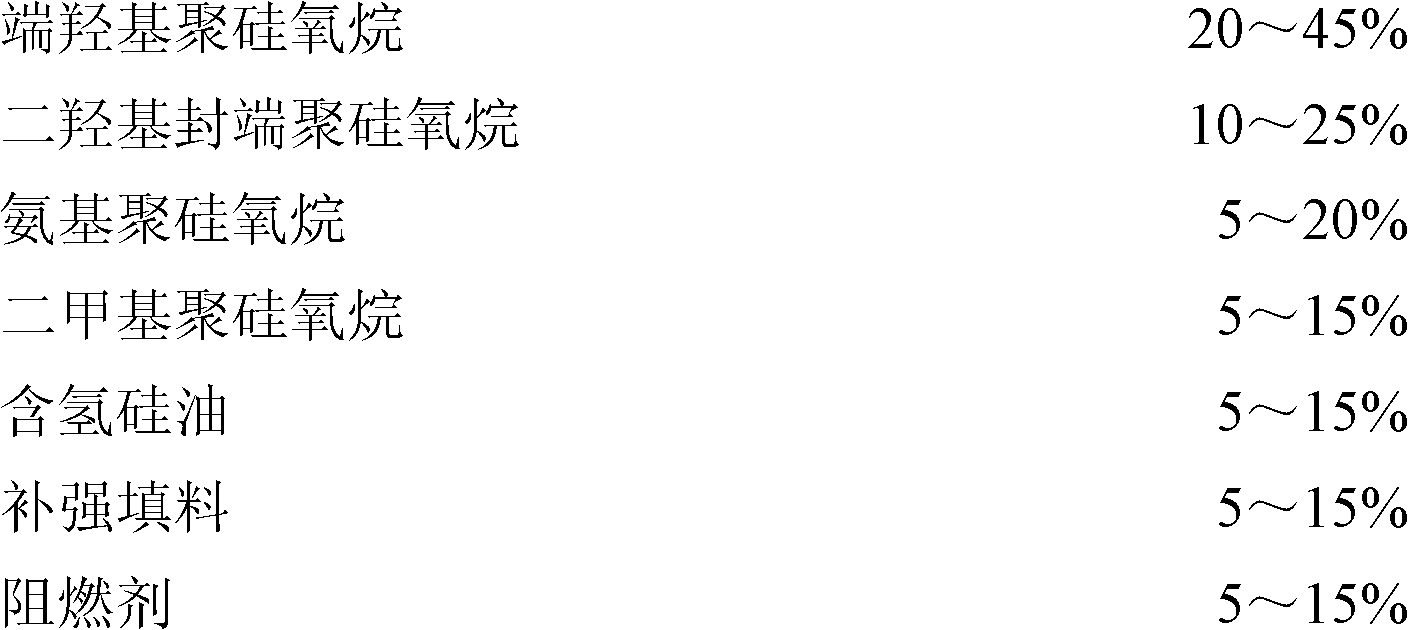

[0047] The composition formula of A component is as follows:

[0048]

[0049]

[0050] The composition formula of B component is as follows:

[0051]

[0052] All the other contents are the same as those described in Example 1.

Embodiment 3

[0054] The composition formula of A component is as follows:

[0055]

[0056] The composition formula of B component is as follows:

[0057]

[0058]

[0059] All the other contents are the same as those described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com