Method for preparing compound fertilizer from salt manufacturing mother liquor

A compound fertilizer and mother liquor technology, applied in chemical instruments and methods, phosphorus compounds, fertilization devices, etc., can solve the problems of complex process route, high energy consumption, difficult to popularize and apply, etc., and achieve cost reduction, simple process and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

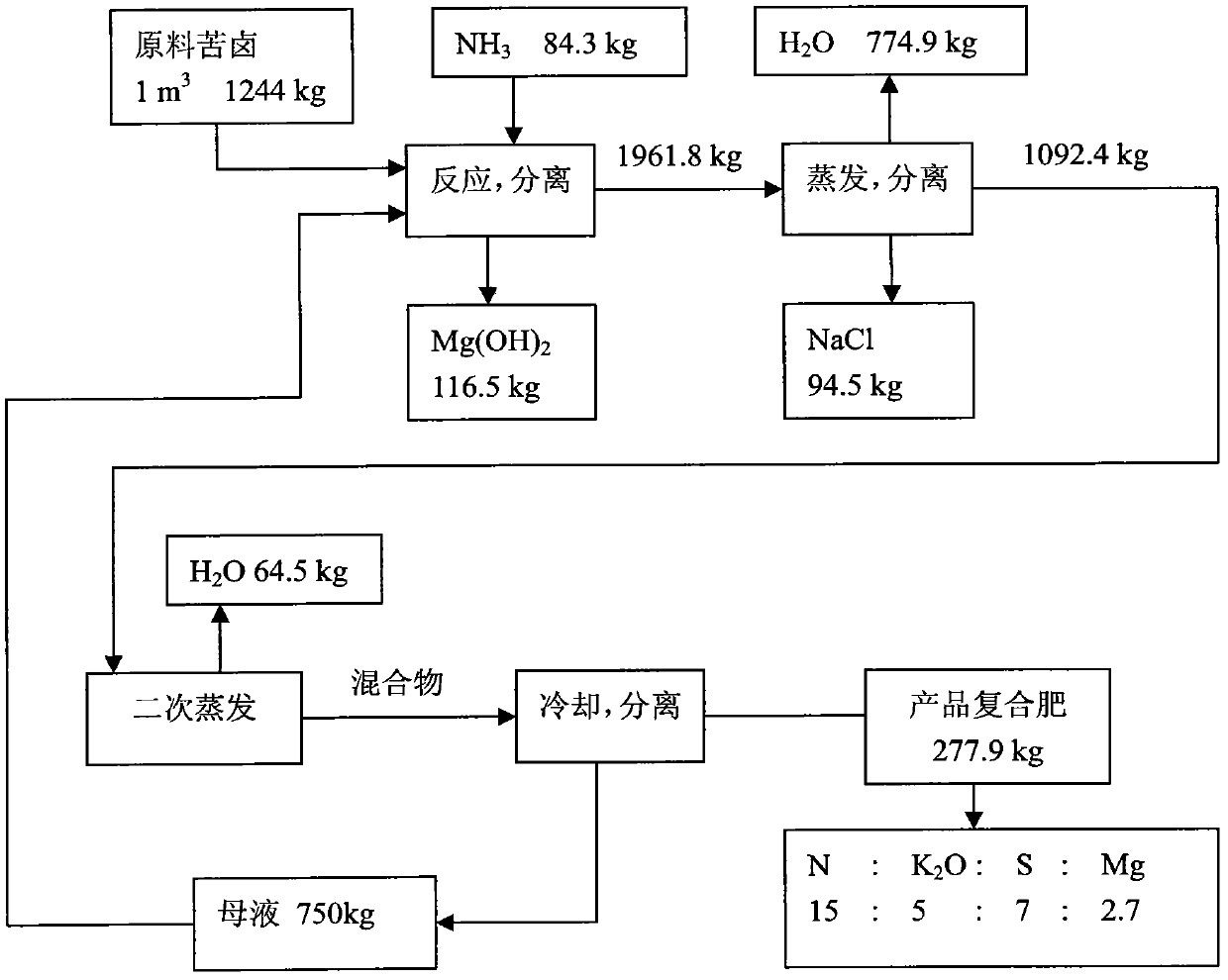

[0034] This example is an example of using the technology of the present invention to produce nitrogen, potassium, magnesium, and sulfur quaternary compound fertilizers using the salt-making mother liquor (bitrine) and ammonia gas after seawater salt making is a kind of patented technology. actual technical process.

[0035] This process mainly goes through several key steps: reaction-separation, evaporation-separation, evaporation-cooling-separation, mother liquor circulation.

[0036] The first step: reaction crystallization-solid-liquid separation process. This step reaction is based on NH 3 The basic principle is that the aqueous solution is alkaline, and magnesium ions can form intolerant magnesium hydroxide with hydroxide. By introducing ammonia into the bittern, hydroxide and ammonium ions are formed, and then magnesium hydroxide is formed with magnesium ions in the bittern. Introduce nitrogen, the active ingredient of compound fertilizer, into the system. The reactio...

Embodiment 2

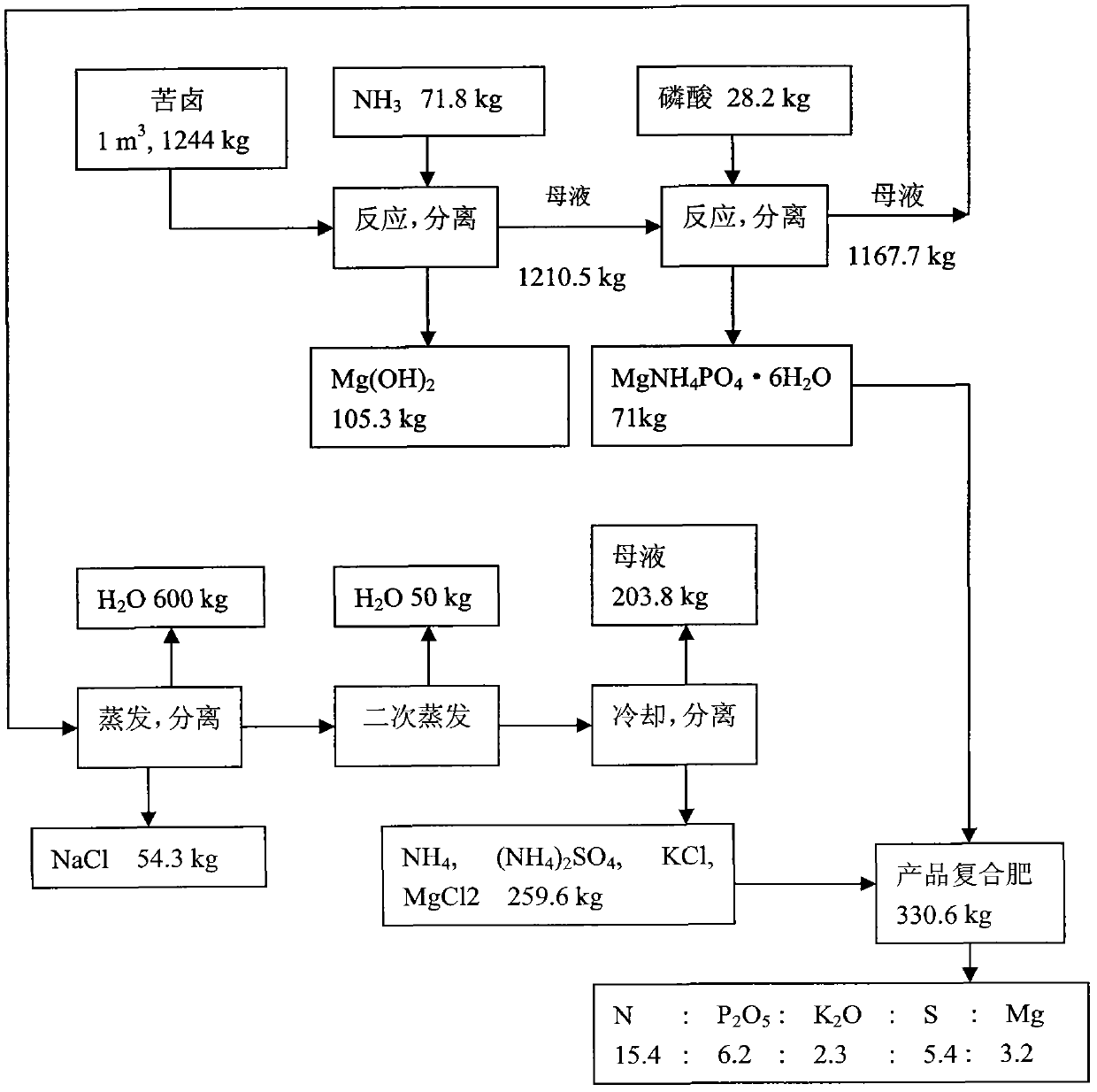

[0044] This example is an example of using the technology of the present invention to produce nitrogen, phosphorus, potassium, magnesium, and sulfur five-element compound fertilizer by using the salt-making mother liquor (bitrine), ammonia and phosphoric acid after seawater salt-making as raw materials. An actual technical process of technology. The main process is several key steps: ammonia reaction crystallization-separation, phosphoric acid reaction crystallization-separation, evaporation-separation, secondary evaporation-cooling-separation.

[0045] The first step: ammoniation reaction crystallization process - solid-liquid separation. The main purpose of this step reaction is to introduce nitrogen, an effective component of compound fertilizer, into the system. The reaction is carried out at normal temperature, and the main control index is that the recovery rate of magnesium is 75-80%. After solid-liquid separation, a mother liquor with ammonium ions is obtained, and t...

Embodiment 3

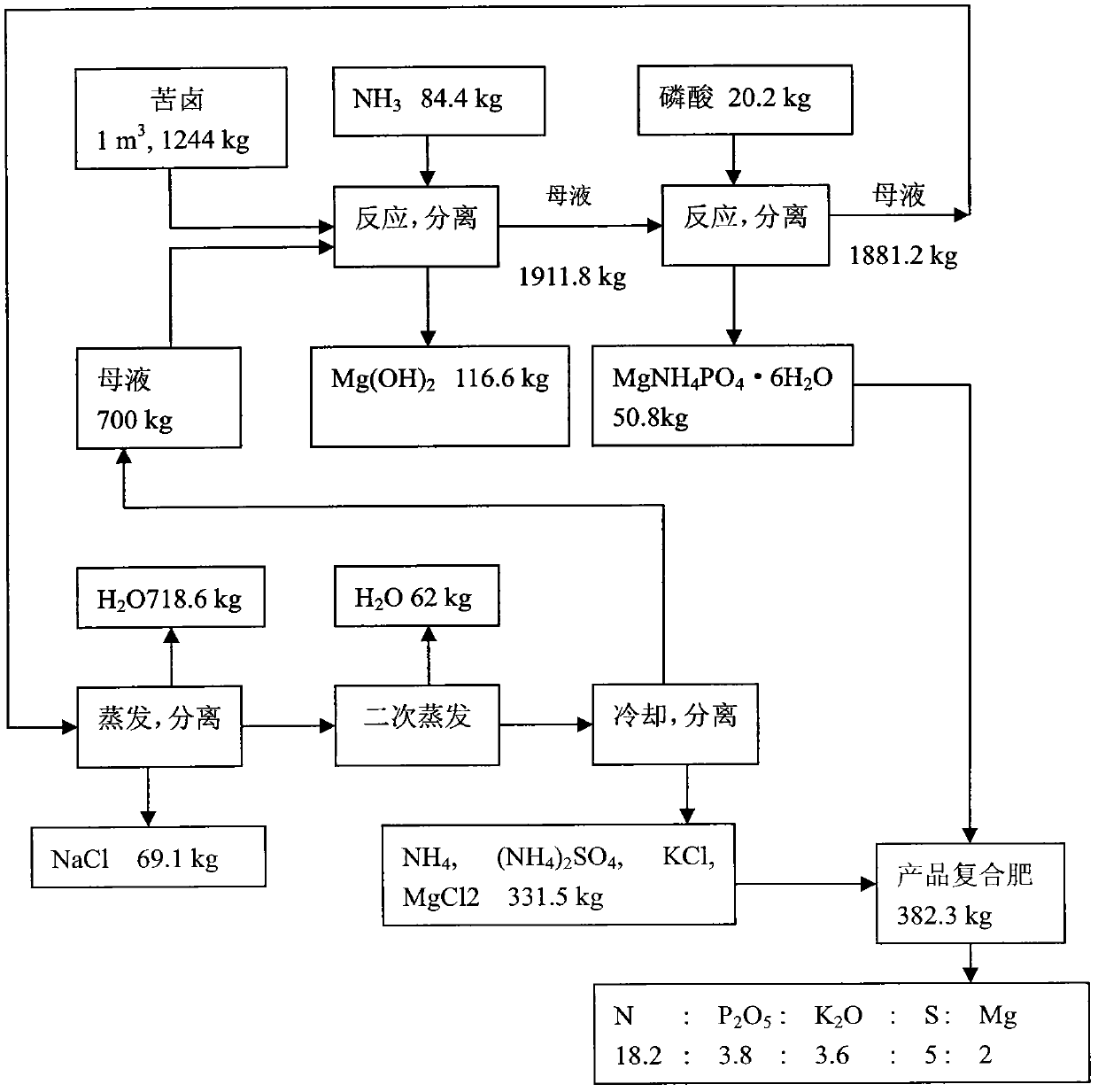

[0051] This example is an example of using this patented technology to produce nitrogen, phosphorus, potassium, magnesium and sulfur five-element compound fertilizer with bittern, ammonia and phosphoric acid after salt production from seawater as raw materials. There is a mother liquor recovery process in the process, which is a practical technical process of this patented technology.

[0052] This process mainly goes through several key steps: ammonia addition reaction crystallization-separation, phosphoric acid addition reaction crystallization-separation, evaporation-separation, evaporation-cooling-separation, mother liquor circulation.

[0053] The first step: the mother liquor in the production process is mixed with the raw material brine. Using mother liquor circulation, all the chemical components in the brine can be precipitated in the form of products.

[0054] The second step: ammoniation reaction crystallization process - solid-liquid separation. The main purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com