Sintering method of self-bonding SiC refractory material

A refractory material, self-combination technology, applied in the field of non-oxide bonded silicon carbide refractory materials, can solve the problems of material quality degradation, performance index reduction, unspecified firing atmosphere, etc., to achieve stable quality, excellent performance, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

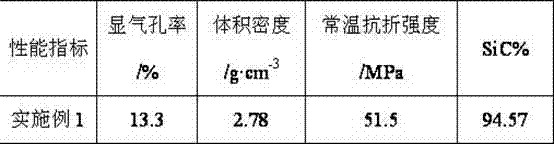

Embodiment 1

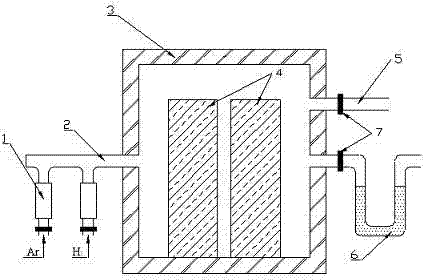

[0016] attached figure 1 What is given is an electric heating or fuel heating atmosphere sintering furnace, and the related equipment has been widely used. The sintering method of the present invention requires the sintering furnace to have good airtightness, so as to ensure the atmosphere control and safe operation of the sintering. sex.

[0017] Self-combined SiC body is prepared, using (mass percentage) 90% industrial grade black SiC particles and fine powder as aggregate, 7% silicon powder, 3% high-purity carbon powder, mixed with a hydraulic press to form.

[0018] The sintering temperature of this embodiment is 1500°C; put the dried green body into the atmosphere sintering furnace, pass through the pure Ar and then ignite the furnace, with a heating rate of 3°C per minute to 1400°C, and convert the atmosphere in the furnace to pure H 2 , when the temperature rises to 1500°C, heat preservation starts, and it is fired at this temperature for 15 hours. After the heat prese...

Embodiment 2

[0023] Preparation of self-combined SiC body, using (mass percentage) 91% high-purity SiC particles and fine powder, 6.5% silicon powder and 2.5% high-purity carbon powder as raw materials, plus 1% silicon-aluminum alloy, using friction pressing Brick machine molding.

[0024] The sintering temperature of this embodiment is 1400°C; put the dried green body into the atmosphere sintering furnace, pass through the pure Ar and light the furnace, and change the sintering furnace atmosphere to pure H at a rate of 2°C per minute to 1300°C. 2 , When the temperature rises to 1400°C, heat preservation starts, and the heat preservation time is 10 hours. After the heat preservation is completed, the furnace is stopped, converted into pure Ar, and then exits the kiln after cooling. During the whole process, the pressure difference of the U-shaped tube is maintained at (80-100) mm water column.

[0025] The performance indexes of the prepared refractories are shown in Table 2.

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com