Treatment chemical for lead-zinc flotation tailing wastewater

A wastewater treatment and flotation tailings technology, which is applied in mining wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor technical and economic operability, high treatment cost, single drug effect, etc., and achieve the removal of precipitated heavy metals Ion, less dosage, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: The composition and weight percentage of this lead-zinc flotation tailings wastewater treatment agent are: 90% ammonium bicarbonate, 9% sodium phosphate, and 1% non-ionic polyacrylamide.

[0016] When in use, mix 90% of ammonium bicarbonate, 9% of sodium phosphate and 1% of non-ionic polyacrylamide according to the weight percentage, mix and stir evenly, add water to prepare a concentration of 2%, and put it into the treatment agent storage tank 1 for standby.

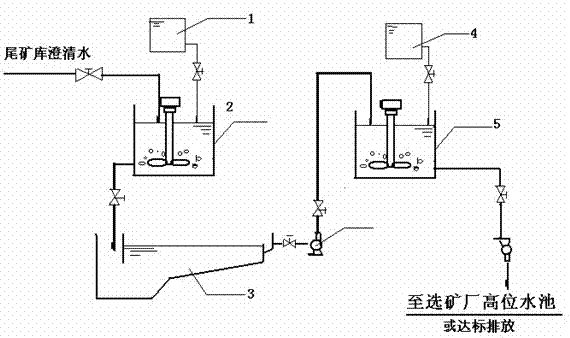

[0017] exist figure 1 Among them, the lead-zinc flotation plant tailings wastewater containing high calcium, high pH, and high heavy metal ions first enters the tailings pond for clarification, and the clarified water from the tailings pond is pumped to the No. Under the condition of high pressure, add 700 mg / L of the treatment agent with a concentration of 2%, and stir for 5 minutes, so that the chemical reaction with the free calcium oxide and heavy metal ions in the wastewater can fully occur...

Embodiment 2

[0021] Example 2: The composition and weight percentage of the lead-zinc flotation tailings wastewater treatment agent are: 80% sodium bicarbonate, 19% sodium tripolyphosphate, and 1% non-ionic polyacrylamide.

[0022] When in use, mix 80% sodium bicarbonate, 19% sodium tripolyphosphate and 1% non-ionic polyacrylamide according to the weight percentage, mix and stir evenly, add water to prepare a concentration of 5%, and put it into the treatment agent storage tank for later use.

[0023] Lead-zinc flotation plant tailings wastewater containing high calcium, high pH, and high heavy metal ions first enters the tailings pond for clarification, and the clarified water from the tailings pond is pumped to the No. Next, add 450 mg / L of the treatment agent with a concentration of 5%, and stir for 10 minutes, so that the chemical reaction with the free calcium oxide and heavy metal ions in the wastewater can fully occur in the No. 1 mixing tank to form a precipitate. At the same...

Embodiment 3

[0027] Example 3: The composition and weight percentage of the lead-zinc flotation tailings wastewater treatment agent are: 85% ammonium carbonate, 14.2% sodium dihydrogen phosphate, and 0.8% non-ionic polyacrylamide.

[0028] When using, mix 85% of ammonium carbonate, 14.2% of sodium dihydrogen phosphate and 0.8% of non-ionic polyacrylamide according to the weight percentage, mix and stir evenly, add water to prepare a concentration of 4%, and put it into the treatment agent storage tank for standby.

[0029] Lead-zinc flotation plant tailings wastewater containing high calcium, high pH, and high heavy metal ions first enters the tailings pond for clarification, and the clarified water from the tailings pond is pumped to the No. Next, add 600 mg / L of the treatment agent with a concentration of 3%, and stir for 8 minutes, so that the chemical reaction between the agent and free calcium oxide and heavy metal ions in the wastewater can fully occur in the No. 1 mixing tank to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com