Anti-caking prehydration sodium tripolyphosphate capable of dissolving in saline water quickly and preparation method thereof

A technology for prehydrating sodium tripolyphosphate and potassium tripolyphosphate, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficult industrial production, high requirements, high production costs, etc., and achieve simple production process , solve practical problems, and save overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Example 1

[0018] Weigh 50g potassium tripolyphosphate, 30g sodium pyrophosphate and 40g sodium hexametaphosphate according to the proportion (weight), and then add 10 liters of water to fully dissolve the phosphate in the water to form a uniform solution for the subsequent pre-hydration process.

[0019] Put 250kg of sodium tripolyphosphate material into the fluidized bed. According to XRD measurement, the content of type 1 sodium tripolyphosphate in the material is 20%, and the content of type 2 is 80%. The particle size is controlled at 60-200 mesh. Start the fluidized bed. Spraying the 10 liters of phosphate solution at a spraying rate of 0.4 liters per minute, without heating, controlling the temperature of the material below 30 degrees, mixing thoroughly for 30 minutes, without drying, to obtain a granular pre-hydrated sodium tripolyphosphate product. Collect 40-100 mesh products as qualified products. After crushing with meshes greater than 20 mesh and products under...

Example Embodiment

[0026] Example 2

[0027] Weigh 20g potassium tripolyphosphate, 20g sodium pyrophosphate and 120g sodium hexametaphosphate according to the proportion (weight), and then add 25 liters of water to fully dissolve the phosphate in the water to form a uniform solution for the subsequent pre-hydration process.

[0028] Put 250kg of sodium tripolyphosphate material into the high-speed mixer. According to XRD measurement, the content of trimeric type 1 is 30%, the content of type 2 is 70%, and the particle size is controlled at 60-200 mesh. Start the high-speed mixer and spray For the 25 liters of phosphate solution, the spraying speed is 0.4 liters per minute, without heating, controlling the material temperature below 30 degrees, and mixing thoroughly for 30 minutes without drying to obtain granular pre-hydrated sodium tripolyphosphate products. Collect 40-100 mesh products as qualified products. After crushing with meshes greater than 20 mesh and products under 100 mesh, continue to en...

Example Embodiment

[0031] Example 3

[0032] In this example, potassium tripolyphosphate, sodium pyrophosphate and sodium hexametaphosphate were not added, and 25 liters of water were directly weighed for pre-hydration. Put 250kg of sodium tripolyphosphate material into the high-speed mixer. According to XRD measurement, the content of trimeric 1 type is 50%, type 2 content is 50%, and the particle size is controlled at 60-200 mesh. Start the high-speed mixer and spray the above 25 liters of water, spraying rate of 0.4 liters per minute, no heating, control the temperature of the material below 30 degrees, fully mix for 30 minutes, without drying to obtain granular pre-hydrated sodium tripolyphosphate products. Collect 40-100 mesh products as qualified products. After crushing with meshes greater than 20 mesh and products under 100 mesh, continue to enter the next production cycle.

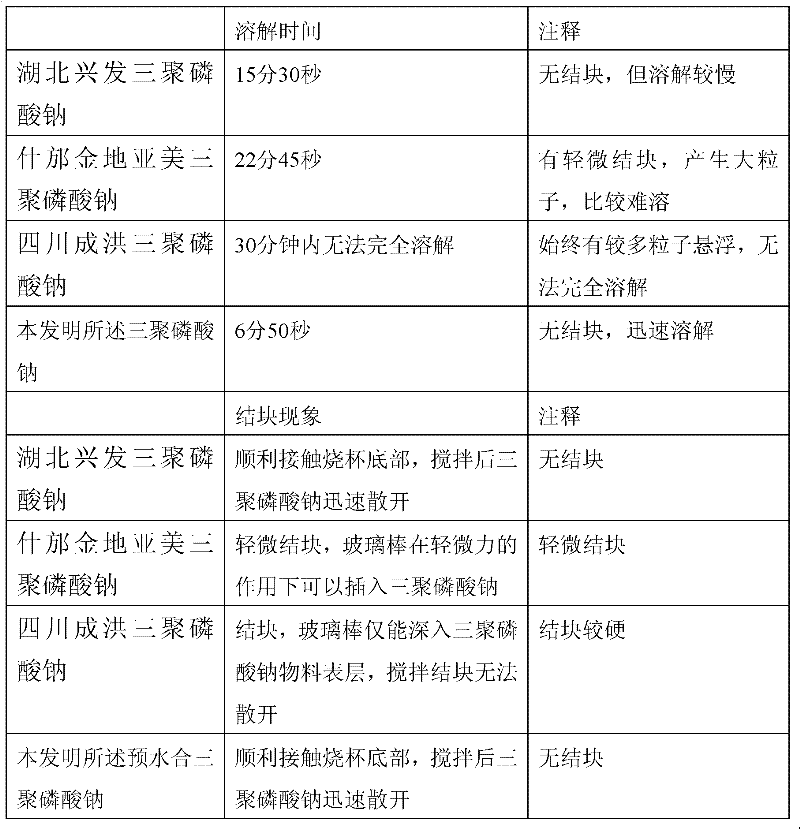

[0033] The dissolution rate and agglomeration of sodium tripolyphosphate in salt water are as follows

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com